WATER IN THIS FUEL WAS NO PROBLEM

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

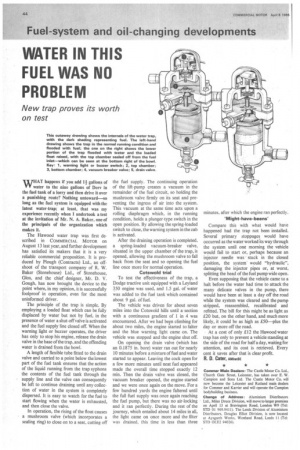

New trap proves its worth on test

WHAT happens if you add 11 gallons of water to the nine gallons of Dery in the fuel tank of a lorry and then drive it over a punishing route? Nothing untoward—so long as the fuel system is equipped with the latest water-trap; at least, that was my experience recently when I undertook a test at the invitation of Mr. N. A. Baker, one of the principals of the organization which makes it.

The Hawood water trap was first described in COMMERCIAL MOTOR on August 13 last year, and further development has satisfied its makers that it is a very reliable commercial proposition. It is produced by Plough (Contracts) Ltd., an offshoot of the transport company of R. W. Baker (Stonehouse) Ltd., of Stonehouse, Glos, and the chief designer, Mr. D. V. Gough, has now brought the device to the point where, in my opinion, it is successfully foolproof in operation, even for the most uninformed driver.

The principle of the trap is simple. By employing a loaded float which can be fully displaced by water but not by fuel, in the presence of water a shut-off valve is activated and the fuel supply line closed off. When the warning light or buzzer operates, the driver has only to stop his engine, release the drain valve in the base of the trap, and the offending water is drained from the bowl.

A length of flexible tube fitted to the drain valve and carried to a point below the lowest part of the fuel tank ensures that the action of the liquid running from the trap syphons the contents of the fuel tank through the supply line and the valve can consequently be left to continue draining until any collection of water in the system is completely dispersed. It is easy to watch for the fuel to start flowing when the water is exhausted, and then close the valve.

In operation, the rising of the float causes a mushroom valve (which incorporates a sealing ring) to close on to a seat, cutting off the fuel supply. The continuing operation of the lift-pump creates a vacuum in the remainder of the fuel circuit, so holding the mushroom valve firmly on its seat and preventing the ingress of air into the system. This vacuum at the same time acts upon a rolling diaphragm which, in the running condition, holds a plunger-type switch in the open position. By allowing the spring-loaded switch to close, the warning system in the cab is activated.

After the draining operation is completed, a spring-loaded vacuum-breaker valve, situated in the upper chamber of the trap, is opened, allowing the mushroom valve to fall back from the seat and so opening the fuel line once more for normal operation.

Cotswold trial

To test the effectiveness of the trap, a Dodge tractive unit equipped with a Leyland 350 engine was used, and 1.5 gal. of water was added to the fuel tank which contained about 9 gal. of fuel.

The vehicle was driven for about seven miles into the Cotswold hills until a section with a continuous gradient of 1 in 4 was encountered. After we had been climbing for about two miles, the engine started to falter and the blue warning light came on. The vehicle was stopped and the engine shut off.

On opening the drain valve (which has an 0.1875 in. bore) water ran out for nearly 10 minutes before a mixture of fuel and water started to appear. Leaving the cock open for a few more minutes until neat fuel appeared made the overall time stopped exactly 12 min. Then the drain valve was closed, the vacuum breaker opened, the engine started and we were once again on the move. For a few hundred yards the engine faltered until the full fuel supply was once again reaching the fuel pump, but there was no air-locking and it ran perfectly. During the rest of the journey, which entailed about 14 miles in all, the light came on once more and the filter was drained, this time in less than three minutes, after which the engine ran perfectly. 'Might-have-beans'

Compare this with what would have happened had the trap not been installed. Several primary stoppages would have occurred as the water worked its way through the system until one morning the vehicle would fail to start or, perhaps because an injector needle was ' stuck in the closed position, the system' would "hydraulic", damaging the injector pipes or, at worst, splitting the head of the fuel pump wide open.

Even supposing that the vehicle came to a halt before the water had time to attack the many delicate valves in the pump, there would have been at least a day off the road while the system was cleared and the pump stripped, reassembled, recalibrated and refitted. The bill for this might be as light as £20 but, on the other hand, and much more likely, it could be as high as £50 plus the day or more off the road.

• At a cost of only £12 the Hawood water trap has only to prevent a vehicle standing at the side of the road for half a day, waiting for attention, and its cost is retrieved. Every cent it saves after that is clear profit.

R. D. Cater, AMIrstBE