Twin-steer tractors save Shell money

Page 22

If you've noticed an error in this article please click here to report it so we can fix it.

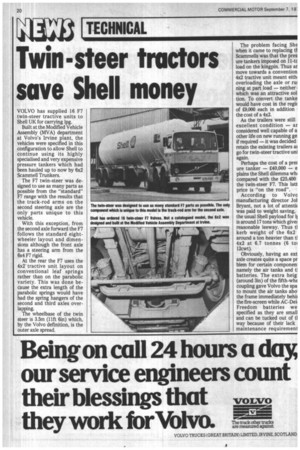

VOLVO has supplied 16 F7 twin-steer tractive units to Shell UK for carrying lpg.

Built at the Modified Vehicle Assembly (MVA) department at Volvo's Irvine plant, the vehicles were specified in this configuration to allow Shell to continue using its highly specialised and very expensive pressure tankers which had been hauled up to now by 6x2 Scamrnell Trunkers.

The F7 twin-steer was designed to use as many parts as possible from the "standard" F7 range with the results that the track-rod arms on the second steering axle are the only parts unique to this vehicle.

With this exception, from the second axle forward the F7 follows the standard eightwheeler layout and dimensions although the front axle has a steering arm from the 6x4 F7 rigid.

At the rear the F7 uses the 4x2' tractive unit layout on conventional leaf springs rather than on the parabolic variety. This was done because the extra length of the parabolic springs would have had the spring hangers of the second and third axles overlapping.

The wheelbase of the twin steer is 3.5m (lift 6in) which, by the Volvo definition, is the outer axle spread. The problem facing She when it came to replacing ti Scammells was that the pres ure tankers imposed on 11-tc load on the kingpin. Thus ar move towards a convention 4x2 tractive unit meant eith, overloading the axle or rui fling at part load — neither which was an attractive sot tion. To convert the tanke would have cost in the regic of £9,000 each in addition the cost of a 4x2.

As the trailers were still excellent condition — ar considered well capable of a other life on new running ge if required — it was decided retain the existing trailers at go for twin-steer tractive uni again.

Perhaps the cost of a pre5 ure tanker — £40,000 e plains the Shell dilemma whi compared with the £25,400 the twin-steer F7. This latt price is "on the road".

According to Volvo manufacturing director Jol Bryant, not a lot of attentic was paid to weight saving, the usual Shell payload for is around 17 tons which give5 reasonable leeway. Thus ti kerb weight of the 6x2 around a ton heavier than t] 4x2 at 6.7 tonnes (6 to 12cwt).

Obviously, having an ext axle creates quite a space pr Nem for certain componen namely the air tanks and t] batteries. The extra heig (around 3in) of the fifth-whE coupling gave Volvo the spa to mount the air tanks abo. the frame immediately behii the fire-screen while AC-Del Freedom batteries we specified as they are small and can be tucked out of ti way because of their lack maintenance requirement