New top A.weight DAFs to replace 2600 series

Page 59

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

DAF, of Eindhoven, has introduced over the past three years new features and cabs on all its truck models except the heaviest range, and today the programme is completed with the announcement ' of a brand new top-of-the-range model, the 2800-series, which will replace the current 2600-series models.

The 2800 series covers a very wide range of types including tractive unit, rigid drawbar and tipper chassis in 4 x 2, 6 x 2 and 6 x 4 form. Rear axles are available in 10 and 13-ton ratings and bogies in 16 or 20-ton ratings. Normal and sleeper cabs are available on any model. Four engine outputs are also offered.

The first DAF 2800 series models are expected to be available in Britain from April 1974 but details as to which models from the vast basic range will be offered here have not yet been announced.

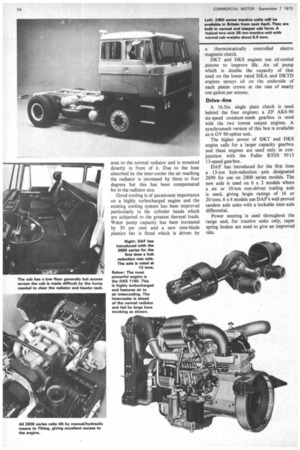

TN cab The 2800 series cab shares many panels of the lighter models but is stretched to full width and given a very distinctive styling of its own. An important feature is that the cab is now tiltable — to 70 degrees by a hand-operated hydraulic pump. Daily oil and water checks can be made through the grille without needing to tilt the cab. Despite the vertically mounted in-line engine, the central engine cover is quite shallow, giving a very roomy cab. On the sleeper cab models the seats are Bostrom Viking 300 suspension types which are upholstered in a breathing-fabric material. The mate's seat is additionally fitted with arm and head rests.

The driving position is basically good but the large diameter horizontal wheel seems strangely old. fashioned compared to the new Leyland Marathon's and the seat only adjusts for height by sliding up and down a ramp. Raising the seat

means it moves rearwards and lowering vice versa, which is not such a good system as separate height and reach adjustments. The instruments are big and clear and have non-reflective glass lenses for easier reading, but are mounted low down, well below the bottom edge of the screen. Three wipers clear 90 per cent of the screen area outside and a full width of demister vents should keep it clear from the inside. Headroom for a top weight Eurotruck is sufficient but well below average.

Four engine ratings The same basic engine is retained for the 2800 series, ie an in-line 11.6-litre four-stroke diesel. but it is now available in four power ratings to satisfy the needs of particular markets. The lowest output version is the DKA 1160 which is normally aspirated but uses a ram induction intake manifold. Above about 1500 rpm the ram induction effect produces 5 bhp more than a conventional manifold; maximum power is 230 bhp DIN at 2200 rpm and maximum torque 592 lb ft at 1300 rpm.

The next level of output available is 260 bhp DIN, again at 2200 rpm, and 658 lb ft torque at 1450 rpm. This engine is designated DKTD 1160 and the extra power is achieved by moderate turbocharging. A somewhat higher degree of turbocharging is used for the next level of output in the DKT 1160 engine which produces 290 bhp DIN at 2200 rpm and 795 lb ft torque at 1400 rpm.

The most powerful engine offered is the DKS 1160; this engine is rated at 320 bhp DIN at 2200 rpm and 830 lb ft at 1450 rpm. A very high level of turbocharging of 14.7 psi is used in this engine and to maintain engine life an air to air intercooler is fitted as standard. Turbocharging to this pressure increases air temperature from an ambient of 20 deg C to 110deg C but use of the intercooler reduces the temperature to 35deg C with little loss of pressure before entering the cylinders. The intercooler is similar in area to the normal radiator and is mounted directly in front of it. Due to the heat absorbed by the inter-cooler the air reaching the radiator is increased by three to four degrees but this has been compensated for in the radiator size.

Good cooling is of paramount importance on a highly turbocharged engine and the existing cooling system has been improved particularly in the cylinder heads which are subjected to the greatest thermal loads. Water pump capacity has been increased by 30 per cent and a new nine-blade plastics fan is fitted which is driven by a thermostatically controlled electro magnetic clutch.

DKT and DKS engines use oil-cooled pistons to improve life. An oil pump which is double the capacity of that used on the lower rated DKA and DKTD engines sprays oil on the underside of each piston crown at the rate of nearly one gallon per minute.

Drive-line

A 16.5in. single plate clutch is used behind the four engines; a ZF AK6-90 six-speed constant-mesh gearbox is used with the two lowest output engines. A synchromesh version of this box is available as is GV 90 spitter unit.

The higher power of DKT and DKS engine calls for a larger capacity gearbox and these engines are used only in conjunction with the Fuller RT(0) 9513 13-speed gearbox.

DAF has introduced for the first time a I3-ton hub-reduction axle designated 2699 for use on 2800 series models. The new axle is used on 6 x 2 models where a six or 10-ton non-driven trailing axle is used, giving bogie ratings of 16 or 20 tons. 6 x 4 models use DAF's well-proved tandem axle units with a lockable inter-axle differential.

Power steering is used throughout the range and, for tractive units only, taper spring brakes are used to give an improved ride.