A Giant Constructor

Page 56

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

Scammell Developments are New 30-tonner, Scarab with Oil Engine and Frameless Tanker for Powders

HREE new vehicles will be shown at Earls Court by Scammell

Lorries, Ltd., Watford, in addition to a bodied version of the articulated 24-ton eight-wheeler, a roadtest report of which was published in the August 31 issue of The Commercial Motor. These comprise a heavier Constructor 6 x 6 oilfield semi-trailer outfit, with a rated weight capacity of 30 tons, a Scarab oil-engined &tomer and a bulk powder carrier, which will he seen in the demonstration park discharging material into a silo. The tractor of the bulk, carrier is a Scammell 15-ton unit powered by a Gardner 6LW oil engine.

The unladen weight of the new Constructor equipped with a body is 16 tons 3 cwt., which represents an increase of approximately 3 tons. The wheelbase is 25 ft. l in., compared with a maximum wheelbase of older models of 21 ft. 9 in. The gross bogie loading is now 39 tons and that of the front axle is 71 tons.

Tyres on the bogie have been increased in section from 14.00 in. by 20 in. to 14.00 in. by 24 in. to accommodate the higher loading, the 14.00-in. by 20-in. tyres at the front being unchanged. The bogie centres have been increased from 4 ft. 8 in. to 4 ft. 11 in. to provide for the heavier tyres.

An increase in the rear track from 6 ft. 61-1in. to 6 ft. 1l in. has enabled straight side frame members to be used, which materially facilitates body mounting. The overall width of 9 ft. 11 in. compares with a former width of 9 ft. 3 in. The overall length has been increased from 30 ft. 10 in. to 34 ft. 44 in.

TheRolIs-R oyce C6NFL six-cylindered direct-injection oil engine has been uprated to 200 b.h.p. at 2,100 r.p.m., whereas older Constructor chassis were

equipped with a similar engine rated at 185 b.h.p. at 2,100 r.p.m. Following the original practice, the drive is transmitted through a six-speed gearbox with high-pressure lubrication and a twospeed transposing box, giving a total of 12 speeds. The front-axle 'ratio is 9.4 to 1; whilst the rear-axle ratio has been increased to 10..25 to 1.

Apart from the dimensional, powerrating and weight-capacity changes, the new Constructor has a number of original features, including a disc hand brake on the transmission, diaphragmtype air-pressure foot brakes and modified propeller-shaft mountings. Another detail of interest is an adjustable anchorage for gin-pole check chains.

Developed for the Constructor application in conjunction with Girling, Ltd., the transmission brake is of the single-caliper type and is operated by cable, caliper actuation being on the wedge principle. The cast-iron 16-in. disc is ventilated to increase cooling and a good wearing life is provided by circular pads of 2+-in, diameter which have a useful thickness of 1+ in. The brake is capable of holding a fully laden vehicle on a gradient of 1 in 8.5. Normally it will be employed only as a parking brake.

To provide the necessary flexibility for the disc and to accommodate the braking-force reaction, a new type of spider mounting with Metalastik rubber bushes was introduced, and it was then decided to replace all but the rearmost propeller-shaft mountings with the same type, which has the advantage that it reduces vibration. A rubber-bushed self-aligning •cone end mounting is retained because of the angular movement of the final propeller shaft. There are now nine propeller, shafts, an Lnerease of two compared with those of the smaller Constructor.

Weight saving and the elimination of ;!xposed pin joints are the advantages provided by the BendixWestinghouse diaphragm-type braking equipnient at the. rear. The, diaphragm units; whiCh are mounted directly on the Wheel raSsemblies, take the -place of air= -pressure Olinders attached : to the torque arm which actuated the brake shoes by. means of cross-shafts, rods and niggle levers, • The braking effort at the rear has been stepped up by an amount commensurate with increased bogie loading.

Suspension details of the chassis remain unchanged,but whereas. the lighter Constructor mbdels are available with laminated leaf springs in plaCe of the solid, beams of the hogie,.the 30tanner is fitted with the, latter without' the option of alternative equipment. Apart from the larger number . of propeller shafts, the transmission layout is also standard, separate drives from the transposing box being provided for the three axles.

. Theheavy-duty winch which will be fitted_ is . a Woodfield Senior. with a capacity of 70,000 lb. The drive incor-: porates an independent 'reversing box, so that the winch can be• operated in both directions with • . the • vehicle' 'stationary. The tail roller assembly is equipped,with skid plates for .a • 941.wide oilfield body.

Byequipping a Scarab 6-tonner with: a Perkins P4 oil engine in place.of the: Searnmell side-valve petrol engine, the power available has been increased from 45 b.h.p. at 3,200 r.p.m. to 52 bh.p. at 2,400 r.p.rtt, and tests have shown that, irt congested city service, the fuel consumption i improved by nearly 100 per cent. A consumption rate of 17-18-m.p.g. js.., now obtainable.

To .enable the niaximum'advantage to be taken Of the higher torque rating of the oil engine, the back-axle ratio has been reduced, from 11,5 to 1 to 7.5 to 1, The only other modification is the use of slipper-type semi-elliptic leaf springs at the rear.

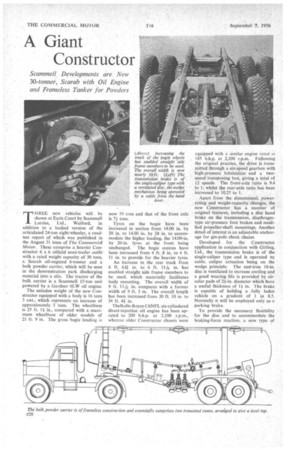

Designed by Scarramell, with a • development period of over six years, the bulk powder carrier represents a trend of growing importance to. the national economy, and it is significantthat the tanker will be supplied to Unilever, Ltd., who are among the foremost users of the latest mechanical

handling Methods: •

Of halite-less construction, the' fourWheeled tanker Semi-traifer. essentiallycomprises two truncated steel cdtiesarranged to provide a fiat top with the deepest section-in the centre. Thertank is divided into three compartments and has three discharge points grouped in front of the bogie. Air :is supplied by a' compressor on the tractor driven from the power take-off, to the top of the compartments, and is initially employed to. aerate the material and later to discharge the poWder Under top .pressure.