IMPROVEMENTS

Page 42

Page 43

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

All Along the Line

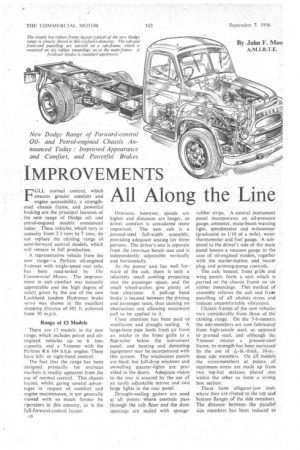

New Dodge Range of Forward-control Oiland Petrol-engined Chassis Announced Today : Improved Appearance and Comfort, and Powerful Brakes By John F. Moo

A.M.I.R.T.E.

• normal: control,' .which ensures 'greater cortifOrt and engine accessibility, •a strength-ened chassis frame, and powerful braking are the principal features of the new range. of :Dodge oiland petrol-erigined models announced . today. ,These vehicles, which vary in capacity froni 23 tons, to 7 tons, do not replace. the existing range of semi-forward control Models, which will remain in full production.

A representative vehicle from the new range—a Perkins oil-engined 5-tOnner with single-speed rear axle, has been road-tested by The Commercial Motor. The improvement in cab Comfort was instantly' appreciable and the high degree of safety given by the use of the new Lockheed tandem Hydrovac brake servo was shown in the excellent stopping distance of 481 ft. achieved from 30 m.p.h.

Range of 13 Models There are 13 models in the new range, which includes petrol and oilengined vehicles up to 6 Ions capacity, and a 7-tonner with the Perkins R.6 104 b.h.p. engine. These have leftor right-hand control.

The fact that the range :has been designed primarily for overseas markets is readily apparent from the use of normal control. This chassis layout, whilst giving several advantages in respect of comfort and engine maintenance, is not generally viewed with so Much favour by operators in this country, as is the full-forward-control layout.

c6 Overseas, however, speeds are higher and distances are longer, so driver comfort is considered more important. The new cab is a pressed-steel full-width• assembly, providing adequate seating for three persons. The driver's seat is separate from the two-man bench seat and is independently adjustable vertically and horizontally.

As the power unit lies well for-fl of the cab, there is only a

relatively small cowling projecting into the passenger space, and the small wheel-arches give plenty of foot clearance. A pull-up hand brake is located between the driving and passenger seats, thus causing no obstruction and allowing maximum pull to be applied to it.

Close attention has been paid tot ventilation and draught sealing. A large-bore pipe feeds fresh air from an intake in the front grille to a flap-valve below the instrument panel, and heating and demisting equipment may be incorporated with this system. The windscreen panels are fixed, but full-drop windows and swivelling quarter-lights are "provided in the doors. Adequate vision to the rear is assured by the use of. an easily adjustable mirror and two

large lights in the rear panel. .

Draught-sealing gaiters are used at all points Where controls pass through the cab floor and the door openings are sealed with sponge rubber strips. A central instrument panel incorporates an oil-pressure gauge, ammeter, main-beam-warning light, speedometer and mileometer (graduated to 1/10 of a mile), water thermometer and fuel gauge. A subpanel to the driver's side of the main panel houses a vacuum gauge in the case of oil-engined models, together with the starter-button and heater plug and priming-pump controls.

The cab, bonnet, front grille and wing panels form a unit .which is .carried on the chassis frame on six rubber mountings. Thi's method of assembly relieves the cab and frott panelling of all chassis stress and reduces uncomfortable. vibrations.

ChassiS frames ofthe new ‘"iehieles. vary considerably from those of the existing ,:ra:ng.e.': On the 5-6-formers the side-members arc nom/ fabricated fromhigh-tensile steel, as opposed to pressed steel, and although the 7-tonner retain S a pressed-steel frame, its strength has been increased by the use of -&-in.-thick, 10-in.deep side members. On all. models. the cross-members at points.. of maximum stress. are .made up from. twotop-hat sections placed one within the other to forni a strOng box section.

These have 'alligator-jaw ends where they are riveted to the top and bottom flanges of the side members. The distance between. the • parallel. side members has been reduced to conform to generally accepted dimensions and in the case of the 5-tormer, this is just under 34 in.

Lockheed hydraulic brakes with two-leading-shoe units on all wheels -continue to be used, but 5-6-ton models have the new tandem Hydrovac which gives increased braking power compared with the single unit

formerly used. The 7-tormer has Girling hydraulic braking with a Clayton Dewandre 8+-in.-diarneter vacuum servo, but an air-pressure hydraulic brake system is offered as optional equipment on this model.

Spring-hanger brackets are bolted to the frame to facilitate replacement in the event of damage, and The semielliptic springs now used on all models have half-wrapped eyes.

These are formed by extending the second leaves round the eyes of the main leaves, hut leaving sufficient clearance so as not to interfere with normal spring action.

If a main leaf fractured, the vehicle would still be able to carry on. Rubber trunnions support the -propeller shaft centre-bearing in the case of longand medium-wheelbase chassis, which have two-piece pro

peller' shafts.

A six-cylindered petrol engine, with a maximum output of 116 b.h.p., is offered on models up to 6 tons capacity. Alternatively, the 2-3-tonner may be fitted with a Perkins P.4 55 b.h.p. oil engine and the 5-tonner with the P.6 83 b.h.p. engine, as used in the test vehicle. ,The 6-tonners and 7-tonners are available with the Perkins R.6 104 b.h.p. unit.

Irrespective of power unit, all the new chassis have hydraulic clutch operation, which allows for relative movement between the engine-gear box unit and the clutch pedal. . A pressurized radiator is employed on every model and the radiator is mounted integrally with the front panel of the cab-bonnet assembly.

The standard axles throughout the range are Single-speed spiral-beveldrive units with fully floating • half shafts. Eaton twO-speed axles are available as optional equipment but not, on the 2-3-tonner. These have vacuum-operated change mechanisms except when used on chassis with airhydraulic brakes, in which case electrical control is specified.

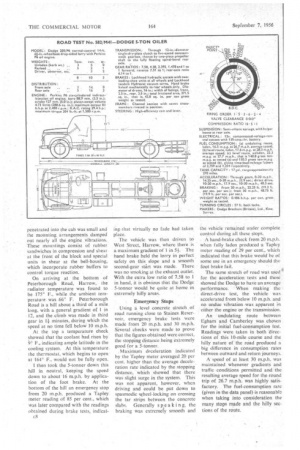

Unladen Weight 3i Tons The test, chassis was in standard trim as a 5-ton oiler, with the exception that helper leaves were incorporated in The rear" springs. -It had a 15-ft. drop-sided timber body and an unladen-weight check showed this to be 3+ tons. In stripped taxation condition this model: weighs 2 tons 181 cwt.

A payload consisting of concrete blocks was placed in the body, complete with securing baulks of timber. and with driver and passenger aboard the gross weight came to 8 tons 101 cwt. The weight distribution was good, the front-axle loading being 2 tons 14 cwt. •

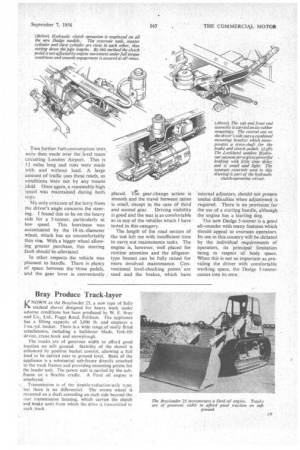

It was decided to make the hillclirnb tests firsr.and. for this the 5tonner was taken to Harrow. Travelling as passenger during this journey I noted the comfort provided by the cab. As I was the only passenger, there was plenty of room to. spread out on the two-man seat and foot-room was entirely adequate:.

The amount of engine noise which penetrated into the cab was small and the mounting arrangements damped out nearly all the engine vibrations. These mountings consist of rubber sandwiches in compression and shear at the front of the block and special units in shear at the bell-housing, which incorporate rubber buffers to control torque reaction.

On arriving at the bottom of Peterborough Road, Harrow, the radiator temperature was found to be 175° F., while the ambient temperature was .66° F. Peterborough Road is a hill about a third of a mile long, with a general gradient of I in 12, and the .climb was made in third gear in 11 minutes, during which the speed at no time fell below 10 m.p.h.

At the top a temperature check showed that the coolant had risen by .0 F., indicating ample latitude in the cooling system. At this temperature the thermostat, which begins to open at 164° F.. would not •be fully open.

I then took the 5-tonner down this hill in neutral, keeping the speed down to about 16 m.p.h. by application of the foot brake. At the bottom of the hill an emergency stop from 20 m.p.h. produced a Tapley meter reading of 85 per cent., which was later compared with the readings obtained during brake tests, indicat c8 ing that virtually no fade had taken place.

The vehicle was then driven to West Street, Harrow, where there is a maximum gradient of 1 in 5+. The hand brake held the lorry in perfect. safety on this slope and a smooth second-gear still was made. There was no smoking at the exhaust outlet. With the extra low ratio of 7.58 to 1 in hand, it is obvious that the Dodge 5-tonner would .be quite at home in extremely hilly areas.

Emergency Stops Using a level concrete stretch of road running close to Staines Reservoir, emergency brake tests were made from 20 m.p.h. and 30 m.p.h. Several checks were made to prove that the figures obtained were correct, the stopping distance being extremely good for a 5-tonner.

. Maximum deceleration indicated by the Tapley meter averaged 20 per cent, higher than the average deceleration rate indicated by the stopping distance, which showed that there was slight surge in the system. This was not apparent, however, when driving and could be put down to spasmodic sziheel-locking on crossing the tar strips between the concrete slabs. Generally speak in g, the braking was extremety smooth and

the vehicle remained under complete control during all these stops.

A hand-brake check from 20 m.p.li. when fully laden produced a Tapley meter reading of 29 petcent., which indiCated that this brake would be of some use in an emergency should the foot brake fail.

The same stretch of road was used for the acceleration tests and these showed the Dodge to have an average performance. When making the direct-drive test, the vehicle was accelerated from below 10 m.p.h. and no undue vibration was apparent in either the engine -or the transmission.

An undulating route between Egham. and Camberley was chosen for the initial fuel-consumption test. Readings were taken in both directions of this 10-mile course and the hilly nature of the road produced a big difference in consumption rates between outward and return journeys.

A speed of at least JO m.p.h. was maintained whenever gradients and traffic conditions permitted and the resulting average speed for the round trip of 26.7 m.p.h. was highly satisfactory. The fuel-consumption rate (given in the data panel) is reasonable when taking into consideration the many stops made and the hilly sections of the route. . Two further fuel-consumption tests, were then made over the level route circuiting London Airport. This is 12 miles long and runs were made with and without load. A large amount of traffic uses these roads, so conditions were not by any means ideal. Once again, a reasonably high speed was Maintained during both tests.

'My only criticism of the lorry from the driver's angle concerns the steering. I found this to be on the heavy side for a 5-tonner, particularly at low speed. This heaviness was accentuated by the 18-in.-diameter wheel, which has an uncomfortably thin rini. With a bigger wheel allowing greater purchase, this steering fault should be alleviated.

In other respects the vehicle was pleasant to handle. There is plenty of space between the /three pedals, and the gear lever is conveniently. placed. Tre gear-change action is smooth and the travel between ratios is small, except in the case of third and second gear. Driving visibility is good and the seat is as comfortable as in any of the vehicles which I have tested in this category.

The length of the road section of the test left me with insufficient time to carry out maintenance tasks. The engine is, however, well placed for routine attention and the alligatortype bonnet can be fully raised for more involved maintenance. Conventional level-checking points are used and the brakes, which have

"internal adjusters, should not present undue difficulties when adjustment is required. There is no provision for the use.of a starting handle, although the engine has a starting dog.

The new Dodge 5-tonner is a good all-rounder with many features which should appeal to overseas operators. Its use in this country will be dictated by the individual requirements of operators, its principal limitation being in respect of body space. When this is not so important as providing the driver with comfortable working space, the Dodge 5-tonner comes into its own.