NEW ARRIVAL OFFERS I ( QUALITY

Page 64

Page 65

Page 66

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

FOR a: Continental vehicle manufacturer to set up a sales organization in Great Britain for his products, despite heavy import 'duties, indicates that the concern • has great faith in the ability of its vehicles to compete against indigenous products. This is undoubtedly so in the case of Daimler-Benz, A.G.,whose goods vehicles are being imported into this country for the first time since

the war.

The high quality of the current Mercedes-Benz goodsvehicle design is immediately apparent to anyone who cares to look for it, and the exceptionally well-finished cab reflects the standard of the mechanical units. Quality .conapensates for the high price, but an equally important consideration is that the items fitted as standard are classed and charged as extras by many British 'makers. In fact, an off-the-peg " Mercedes-Benz 13-ton-gross four-wheeler costs only about the same as an equivalent`British vehicle with all the fittings which are standard on the German model.

The range being brought into this, country for distribution by the concessionnaires, Mercedes-Benz (Great Britain), Ltd., consists of the L31913 oilengined 35-cwt. forward-control chassis, available also in van and lorry forms; 322-series forwardand semi-forward-control 10-tongross four-wheelers and 18-ton-gross 'tractive units; 327type forwardand semi-forward-cOntrol 13-tan-gross fourwheelers and 23-ton-gross tractive units; and 4 x 4 load carriers rated for 10+ ions and tractive units for. 18 tons.

Excellent Performance: Superlative Comfort A full road test of one of the 327-series forward-control four-wheelers was carried out shortly before the Commercial Motor Show, and a brief summary of the results was published in The Commercial Motor on September 16. The model was an LP 327/44 14-ft. 5+-in.-whee1base oilengined chassis. The performance when running at 13 tons gross was most satisfactory, whilst in terms of general handling and driver comfort the vehicle may truly be said to have few equals anywhere in the world.

The LP 327 chassis is the forward-control version of the L 327 semi-forward-control design. Basically, the chassis frame and general layout of these two models differ very little. Both are offered with wheelbases of 14 ft. 5+' in., whilst there is a semi-forward-control version with a wheelbase ,of 16 ft. 4i in. and a .short LP 327 with a wheelbase of 12 ft. 1+ in: The 14-ft. 51-in, forward-Control chassis is suitable for a body length of 21 ft. 21 in., the body fitted to the test vehicle being 20 ft. long.'

Both types of chassiS have the DB OM 3216 5-litre oil engine as standard, It has a gross output of 120 b.h.p. (110 b.h.p. net) at the governed, speed of 3,000 r.p.m., whilst the torque output is 232 lb.-ft. at 1,600 r.p.m. Alternative versions of both typesof chassis, known as the L and LP 337, have the OM 32611V 10.8-litre oil engine, which is rated to develop 172 b.h.p. (net) at 2,200 r.p.m. This unit would be more suitable when the vehicle was intended for use' With a separate trailer.

In both cases the 'standard gearbox has five speeds, all with synchromesh engagement, whilst the standard rear axle of the 327 models is a single-speed. spiral-bevel unit with a reduction ratio of 8.17 to 1. The 337 vehicles have a two-speed spiral-bevel axle with ratios of 4.88 and 6.88 to I. A Daimler-Benz two-speed axle giving ratios of 7.17 and 10 to 1 is also offered in the 327 series and was fitted to the vehicle tested.

Thus, the relatively low nominal power output of the D16 vehicle was amply compensated for by the doubling-up of the main gearbox ratios. This combined with the available engine speed of 3,000 r.p.m. to give a particularly lively performance on both level and hilly stretches of road.

The two-speed axle ratios and the ratios of the standard gearbox are particularly well matched, and there is no overlapping of ratios, as often occurs when a proprietary two-speed axle is employed in conjunction with a chassis manufac turer's gearbox. Thus, the road speeds in second, third, fourth and top gears, with low and high axle ratios engaged, were 3, 9, 11, 14, 19, 22, 30, 36 and 48 m.p.h. respectively at maximum governed engine speed. Under normal main-road conditions, it was rarely necessary to engage a lower ratio than fourthlow, whilst normal cruising speeds could be maintained by using toplow and high ratios.

The standard chassis frame has 1-in.-thick members and the seven cross-members, which have alligatorjaw ends, are riveted in position, except for those in the vicinity of the spring-hanger brackets, where bolts are employed. The frame side members, have a maximum depth of 10 in., and the flanges are 24 in. wide.

Semi-elliptic springs are employed at both axles, with telescopic dampers at the front and helper leaves at the rear. The springs arc long by British standards, those at

the front having an effective. length of 57 in., whilst the rear springs are 71 in. long. The use of Daimler-Benz recireulatory-ball steering ensures minimum steering friction and gives light handling, even when fully laden, without any need for power assistance.

• Ate-Lockheed hydraulic braking equipment is assisted by a Westinghouse air-pressure servo, which operates at a: maximum pressure of 76 p.s.i. The wheel brake units have leading and trailing shoes and give a total frictional area of 440 sq. in. The multi-pull hand-brake lever actuates the rear brakes only.

The standard forward-control cab supplied with this vehicle is of all-steel construction, with plain but pleasing lines. The standard of finish, both inside and out, is extremely high, and the detail fittings inside the cab are numerous. They include two ashtrays, two coat hooks, two padded sun visors, a glove locker with hinged lid, rubber floor mats, head lining, two-man passenger seat, fully detachable driving seat and deep pockets in each door.

Access to the cab is easy because of the provision of steps ahead of the front wheels, whilst the full-widthonepiece curved windscreen gives a good range of vision. The cab has a three-point mounting, with one of the points sited centrally at the rear.

The test vehicle had Boalloy 20-ft. drop-sided body with light-alloy framing and timber floorboards. The kerb weight of the complete vehicle was 4 tons 6 cwt. Test weights totalling 8 tons 11 cwt. had been placed to keep the front-axle rating down to 4 tons with the cab empty,

although the permissible rating is 41 tons and that of the rear axle is 8-1.tons, giving 13 tons all told.

My first test was concerned with fuel consumption, and was conducted on a 12-mile out-and-return circuit along Western Avenue, which included several roundabouts and two sets of traffic lights, and was extremely busy. Several traffic stops were made during the test, and I had to change down to fourth-high when balked on hills. Nevertheless, the circuit was completed at an average speed of 26 m.p.h. and the test tank indicated a consumption rate of 12.4 m.p.g. Under clearer traffic conditions, which would have allowed more continuous use of the top-high combination of ratios, 14 m.p.g. should have been obtained.

On the second day of the test the same 12-mile route was retraced with the test load removed. On this occasion the average speed was 28.8 m.p.h. and the average consumption rate was 19 m.p.g. Operators running laden inonly one direction can expect to achieve 15-16 m.p.g. under normal service conditions.

Fast Acceleration

After the laden consumption test, acceleration times up to 30 m.p.h. were taken from a standstill, using second, third and fourth gears, and from 10 m.p.h. in direct drive, low axle ratio. Between 0 and 30 m.p.h., the performance was lively, and even the direct-drive results were commendable in view of the comparatively small engine. The transmission, however, was rather rough and noisy at 9 m.p.h. in direct drive. Braking tests followed next, and good retardation characteristics were obtained when making full-pressure Stops from 20 m.p.h. and 30 m.p.h. There was no apparent time-lag in the system, but rear-wheel locking produced differences between the average deceleration indicated by the stopping distances and the maximum efficiency shown on the Tapley meter.

Hill tests were carried out on Hedsor Hill, in the Marlow area. Its gradient is half a mile long with an average severity of 1 in 13, the steepest section being 1 in 9. The ambient temperature was 58° F., and a brisk climb was made in 21 minutes, the speed on no occasion dropping below 8 m.p.h. The lowest ratio engaged was third-low, which I used for two minutes.

Unfortunately, the shape of the radiator filler-neck made it impossible to insert a stick thermometer, but the temperature gauge in the instrument panel was recording 180° F. before and after the climb, although it did rise slightly above this level at one stage during the ascent. It was obvious, however, that the cooling system was entirely adequate.

Fade. Test To test for fade resistance I coasted the Mercedes-Benz down the bill in nentral, using the foot brake to ratriet the maximum speed to 20 m.p.h. This descent lasted 2 minutes 12 seconds,_ and at the bottom of the hill a " crash " atop from 20 M.p.h. gave, a Tapley-meter reading of 40 per cent.—a reduction of 22 per cent compared; with: the cold-drum figure Obtained earlier in the day. The degree of fade recorded wasfairly reasonable, and there was no emission of smoke or smell from the brakes.

Oaring a second descent I relied solely on the engine exhaust brake, except on the steepest section, when I momentarily touched the foot brake to allow me to change from fourth-high into third-high after the road speed had risen to 25 m.p.h. The rest of the. descent was carried Out comfortably in third high at approximately 15-na.p.h.

A hill with a maximum gradient of 1 in 91 was used for the restart test. On this slope a comfortable restart was made in second high without signs of clutch slip. The hand brake 'held the vehicle without trouble, although five pumps were needed to apply it fully. As the unit has controlled release characteristics, it Was easy to release the brake smoothly.

The vehicle handled particularly well and it did not take Me long to become accustomed to the 21-in.-diameter steering wheel, which lies in an almost horizontal Plane. The steering lock was remarkable, and there was good castor action and no suspension interference. There was a marked lightening in the steering when running unladen, but even under such conditions it was positive. The fairly low gearing and the good lock necessitate seven turns of the wheel from lock to lock, but this does not seem to create any particular disadvantage when driving and is not obvious under normal circumstances.

. The gear-change is light, .despite the -rather long lever travel, and the synchromesh appeared to be unbeatable. Slight gearbox whine was emitted when running in the indirect ratios. Light Gear-change A short lever on the left of the steering column controls the air-operated two-speed axle change. The mounting is convenient to use, and particularly fast changes may be made from low to high ratios without difficulty, although I did not seem to bi able to change from high to low without causing slight grating of the gears.

The brakes seemed rather heavy, but for normal stops a pressure of about 25 p.s.i. was sufficient, this being indicated by a second needle on the air-pressure gauge. The exhaust brake, controlled by a lever on the right of the steering column, is convenient to use and is foolproof in operation, stalling of the engine being prevented by interlitakage with the clutch and accelerator pedal, so that when 'either is depressed the exhaust brake is released automatically.

At normal cruising speeds there was little engine noise.

but when approaching the governed speed of 3,000 r.p.m: it became rather raucous. Most sound appeared to come from the fan and compression noises were decidedly less than is normal for an indirect-injection unit. Slight vibration was transmitted to the cab when the engine was idling, indicating that the mountings were not as effective as they might have been.

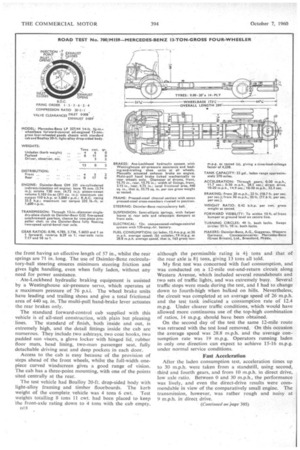

A few maintenance tests were carried out and. shoWed that those components likely to require regular attention were not particularly accessible. For example, it took 43 seconds to check the radiator water level because the filler neck couldbe reached only from inside the Cab by opening a trap on the facia panel (secured by two catches), which revealed a further flap (one catch) before the filler cap was exposed. My time for cheeking thislevel was taken frd'm the mómentf started to' climb into the cab until" I returned tothe ground.

Engine oil level took 51 seconds to check, because the dipstick was not easy to see or reach, despite the provision of .a trap in the left side -of the cowl. I was .unable to check either the rear-axle or the gearbox oil levels, because of the absence of a special key with which to remove the plugs.

Checking the Battery The single battery—specially made by Exideis located beneath the passenger-seat cushions nearest the door. It is reached by hinging up the squab. This can be held in place by a chain which attaches to one of the coat hooks. Then. the cushion can be lifted up and the hardboard panel covering the battery can be lifted off. Although the procedure sounds complicated, it took only 1,1 minutes to _check the cell levels,

" The fluid reservoir for the brake master cylinder is on top of the cylinder and inside the right-hand side member_ It would be impossible to see inside the reservoir to cheek the level, but fortunately this is not necessary as the cap has an integral dipstick. Thus, the level is easy to check and it took only52 seconds.

The engine air cleaner is behind the detachable front grille. This grille is secured by two budget locks, which makes it easy to remove, and the filter bowl is attached by four spring clips to the main body. I was able to check the oil level in this bowl in 70 seconds. Access to the engine is given by raising the one-piece cowl, which is hinged at its front end.

Detachable Gear Lever Because of the conversion from the standard left-handdrive layout, the gear lever tends to obstruct movement of this cowl. Consequently, the lever has been made detachable (with a quick-acting bolt with a lever head). The single passenger-seat cushion has also to be removed, which in turn entails lifting and hooking back the squab. The cowl itself is somewhat heavy because of the amount of insulation provided, and it took me 52 seconds to expose the engine.

With the cowl raised access to the power unit is acceptable, although most of the auxiliary components are on the driver's side—again because of the conversion from left-hand drive.

I did not have time to adjust the brakes, but these should not be difficult to reset, because each has two external adjusters, which are easy to see and reach.