SUPERIO SUPERPOIS

Page 56

Page 57

Page 58

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

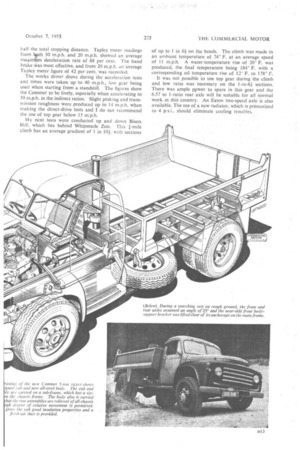

ALTHOUGH. most operators' attention will be focused on the cab and bodywork of the new range of Commer Superpoise vehicles (described in The Commercial Motor last week) it must also be remembered that important improvements have been made to the chassis details. These improvements combine with the new styling to produce vehicles which are pleasing to look at, have a long potential life despite rough treatment, and improved accessibility for maintenance. A further advantage is the optional overdrive unit now available on all models.

A new Superpoise 5-ton end-tipper proved these statements under test and the effortless performance of the vehicle during the two days' trial made me sure that it would take a lot of hard work to break these new Cornmers. Even should a breakdown occur, the good all-round accessibility would reduce off-the-road time to a minimum. .

The vehicle provided for my test was a 5-ton petrolengined tipper, which suited my purposes admirably. Not only did it give me a chance to become fully acquainted with the interesting design of the Commer all-steel tipping body, but I was able to ,run the vehicle over rough ground ruthlessly without fear of being thought unfair.

Tippers spend most of their working life on unmade surfaces, and the Commer has many features which make it suitable for this type of work. These include a new frame which has strength and flexibility, with redesigned cross-members to resist permanent distortion; an improved cab-mounting system which leaves the cab and front-end assembly free of stresses regardless of the flexure of the chassis frame; modified springing to give greater inter-axle articulation and a smoother ride under both laden and unladen conditions; and a rigid, First impressions obtained as a passenger were of the good allround visibility, the adequate ventilation provided by the opening door windows, quarterlights and the fresh-air intake, and the quietness of the power Old and gearbox. On the assumption that what sounds right is right, this was a good omen.

I was disappointed to find that an engine air-cleaner is not fitted as standard to petrol-engined home models. This omission, besides making the engine prone to possible Mechanical troubles—especially with a tipper operating in dusty conditions—also allows induction roar to he heard in the cab when pulling hard.

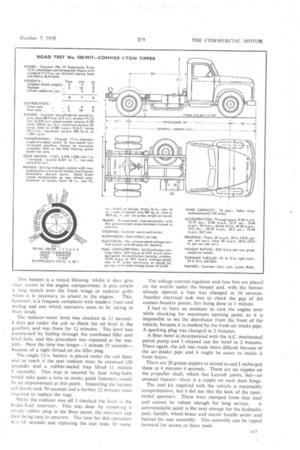

My first tests were made along a quiet, level road near Ilarton-in-the-Clay and covered braking and acceleration. A slight time-lag was apparent in the braking system when making emergency stops, but the figureS obtained were satisfactory. No uneven skidding occurred and when braking from 30 m.p.h., black marks were left on the road by the: rear tyres for approximately

half the total stopping distance. Tapley meter readings from hp th 30 m.p.h. and 20 m.p.h. showed an average inaAirularn• deceleration rate of 68 per cent. The hand Nuke was most effective, and from 20 m.p.h. an average Tapley meter figure of 42 per cent, was recorded.

The works driver drove during the acceleration tests and times were taken up to 40 m.p.h., low gear being used when starting from a standstill. The figures show the C,ommer to be lively, especially when accelerating to 30 m.p.h. in the indirect ratios. Slight pinking and transmission roughness were produced up to 14 m.p.h. when making the direct-drive tests and I do not recommend the use of top gear below 15 m.p.h.

My next tests were conducted up and down Bison. Hill, which lies behind Whipsnade Z00. This i-mile climb has an average gradient of 1 in 10+. with sections

of up to I in 64on the bends, The climb was made in an ambient temperature of 74° F. at an average speed of 11 m.p.h. A water-temperature rise -of• 20 F. was produced, the final temperature being 184° F. with a corresponding oil temperature rise of 12° F. to 178° F.

It was not possible to use top gear during the climb and low ratio was necessary on the 1-in-6+ sections. There was ample ppwer to spare in this gear and the 6.57 to 1-ratio rear, axle will be suitable for all normal work in this country. An Eaton two-speed axle is also available. The use of a new radiator, which is pressurized to 4 p.s.i., should eliminate cooling troubles. A descent was made at 25 m.p.h. with the gear in neutral and the foot brake applied. Not unnaturally, at the bottom of the hill thick smoke was pouring from the brake drums, but an emergency stop from 20 m.p.h. produced a Tapley meter reading of 38 per cent., the pedal travel having increased by 1 in.

After letting the drums cool a return was made to a 1-in-64 section and a stop-start test made. The hand brake held the vehicle satisfactorilY, but to release it, the foot brake had to be applied. A reasonably smooth first-gear start was made at an engine speed of approximately 1,000 r.P.m., it being necessary to slip the clutch slightly when pulling away.

The heavily undulating road between Dunstable and Tring was used for consumption runs, an 8.1-mile trip being made in each direction. On the outward run third gear was engaged on two occasions to tackle hills, and the return leg, being more severe, demanded the use of this ratio four times. The resulting consumption rate of 10.9 m.p.g. at an average speed of 24.5 m.p.h. is entirely reasonable and on longer runs with a smaller percentage of hills, at least 11 m.p.g. should be regularly returned when continuously running laden.

On the following day the same route was covered with the Commer unladen, and on this run 14.75 m.p.g. was returned. Although the same maximum speed was not exceeded, the average speed was higher, because all the hills were climbed in top gear. A combination of the two results obtained gives an average consumption rate of 12.825 m.p.g. and this figure can be expected in service when running laden in one direction and unladen in the other.

To unload the tipper it was taken to a gravel pit near . Luton. The surface was heavily scarred and laced by deep ruts and there were numerous large mounds over which the suspension could be tested. -I was agreeably surprised at the limits to which the Commer could be driven and it was impossible to find a part of the pit bad enough to cause the engine to stall.

250 Angle Between Axles

The degree of axle movement allowed by the suspension can be judged from the fact that on one occasion the front and rear axles were at an angle of 25°, with a 5° angle between the cab and body horizontals. The frame was twisted sufficiently to cause the near-side front body-support bracket to be lifted clear of its support on the main frame, thereby indicating the built-in rigidity of the body itself. It was, however, still possible to open and close the cab doors.

After these contortions the Commer was reversed up to a section of the tip where the load was to be discharged. The remote-control mechanism for the tailgate locking cams enabled me to tip the gravel singlehanded without leaving the cab. It took 35 seconds to release the tail-gate, engage the power take-off and raise the body to its maximum angle of 500. It was not necessary to shake the vehicle much to clear the load completely, as the inside of the U-shr,i)ed body is corn

o14 pletely smooth. Lowering the body took 14 seconds.

The overall performance of this new range should make an immediate appeal to operators of medium-class vehicles. As far as detail points are concerned, I liked the fully adjustable bench seat, the squab of which moves with the cushion; the large cab interior light; the comprehensive instrument panel and neatly arranged controls (which include a hand throttle); and the external cab steps. I think that two driving mirrors should be fitted as standard and opening windscreen panels would be an advantage.

Pleasant to Drive

From the driver's angle, the Commer is pleasant to handle, although the low gearing of the steering (54 turns from lock to lock, compared with 4i turns on the previous range), will seem strange to drivers used to a higher steering ratio, and I would prefer a stronger reverse-stop spring in the otherwise good synchromesh gearbox.

So that T might assess the value of the optional overdrive gear, I conducted a later consumption test on a longwheelbase 5-ton petrolengined chassis. With three people in the cab, the gross weight was 8 tons 51 cwt. Before the test the vehicle had covered 850 miles so it was reasonably free mechanically.

The same return route between Dunstable and Tring was used and two runs were made in each direction. The first out-and-home run was made without engaging the overdrive ratio. The 16.2-mile circuit was covered at an average speed of 28 m.p.h. and an average petrol consumption rate of 11.75 m.p.g. was returned.

This figure is higher than the consumption rate obtained with the short-wheelbase tipper, a peculiarity that can be accounted for only by a possible difference in the atmospheric conditions, a different driver and the slight mechanical variations between the two chassis.

A second run was then made, using overdrive whereever possible. This was completed at an average speed of 28.7 m.p.h. and the rate of fuel consumption averaged 12.4 m.p.g., showing an improvement of 5.5 per cent.

The route chosen was not the kind on which the advantages of an overdrive unit are shown to the full and it was possible to use it for only 70 per cent. of the total running time. In more level country the fuel saving would be more marked and under any condition the overdrive would be an economic proposition when the vehicle was unladen. The test vehicle had the same ratio rear axle (6.57 to 1) and was equipped with 7.5020-in. tyres.

At the conclusion of the road test I returned the Commer to the manufacturers' service department and there carried out a few simple maintenance tasks, the first of these being to check the engine-oil level. This was done in 30 seconds, to which time should be added 20 seconds for raising the alligator bonnet top. This bonnet is a mixed blessing: whilst it does give clear access to the engine compartment, it also entails a long stretch over the front wings or radiator grille

when it is necessary to attend to the engine. This, however, is a frequent complaint with modern front-end styling and one which operators seem to be taking in their stride.

The radiator-water level was checked in 12 seconds. 1 then got under the cab to check the oil level in the gearbox, and was there for lf minutes. The level was ascertained by feeling through the combined filler and level hole, and this procedure was repeated at the rear axle. Here the time was longer-1 minute 55 seconds— because of a tight thread on the filler plug.

The single I2-v. battery is.placed under the cab floor and to reach it the seat cushion must be removed (20 seconds) and a rubber-sealed trap lifted (1 minute 5 seconds). This trap. is secured by four wing-bolts which take quite a time to undo; quick fasteners would be an improvement at this point. Inspecting the battery cell levels took 50 seconds and a further 21 minutes were required to replace the trap.

While the cushion was off I checked the level in the brake-fluid reservoir. This was done by removing a simple rubber plug in the floor panel, the reservoir cap then beng easy to unscrew. The time for this operation was 16 seconds and replacing the seat took 30 more.

The voltage-control regulator and fuse box are placed on the scuttle under the bonnet and, with the bonnet already opened, a fuse was _changed in 14 seconds. Another electrical task was to check the gap of the contact-breaker points, this being done in I minute.

I had to have an assistant to turn the engine over while checking for maximum opening point, as it is impossible to see the distributor from the front of the vehicle, because it is masked by the fresh-air intake pipe. A sparking plug was changed in 2 minutes.

A fitter bowl is incorporated with the A.C. mechanical petrol pump and 1 cleaned out the bowl in 2 minutes. There again, the job was made more difficult because of the air-intake pipe and it might be easier to tackle it from below.

There are 28 grease nipples to attend to and I recharged these in 4 minutes 4 seconds. There are no nipples on the propeller shaft, which has Layrub joints, but—an unusual feature—there is a nipple on each door hinge.

The tool kit supplied with the vehicle is reasonably comprehensive, but I did not like the look of the openended spanners. These were stamped from thin steel and cannot be robust enough for long service. A commendable point is the neat storage for the hydraulic jack, handle, wheel-brace and starter handle under and behind the seat assembly. This assembly can be tipped forward for access to these tools.