FLUID FLYWHEELS

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

for LONDON BUSES Experimental Use of the Daimler Fluid Flywheel and Pieselective Gearbox on Three New Vehicles to be Put into Service by the L.G.O.C.

FOR many years it has been realized that transmission systems as a whole are very much behind power units as regards their state of development. However well the conventional clutch and gearbox have worked in practice there is no doubt that both are somewhat crude and that their very crudity contributes in no small measure to -the total burden of maintenance costs which has to be borne by all vehicle users. This is particularly the case with big bus concerns, the troubles of which are magnified by the large number of gear changes daily, consequent upon dense traffic in urban areas.

In May of this year we announced a great forward step made by the Daimler Co., Ltd, Daimler Works, Cove itry. It consisted of a hydro

dynamic device known as the Fluid Flywheel; it has been applied to production-model private cars.'"The same concern has also introduced a pre-selective gearbox, giving silent running on all ratios and instant and silent engagement of gears, with a control below the steering wheel.

We are now informed by the London General Omnibus Co., Ltd., of Broadway House, Westminster, London, S.W.1, l!that it is shortly putting into service three new Daimler chassis equipped with the Fluid Flywheel and the interesting type of gearbox to which we have referred. These vehicles will be used experimentally and their behaviour will be watched with interest by the. engineer and by the general public. It would seem that the combination of transmission innovations will be ideally suited to the arduous work on London streets. The smoothness of drive should appeal strongly to the bus user.

In place of the conventional .clutch is installed the Fluid Flywheel ; this is a hydro-dynamic mechanism which has only two working parts. It requires no control on the part of the driver and cannot cause any jerkiness in the drive. The power is transmitted from the engine by means of the interchanges of energy in a rapidly moving fluid. In consequence starting from rest and takeup are bound to be free from snatch. A great advantage of the system in question is that the engine can be used as a brake in the ordinary way. There is no vibration when overrunning.

A Truly Silent Gearbox. ,

Another striking recommendation for the new transmission layout is that -there is no noise from the gearbox when any ratio is engaged, and? when idling in neutral there is none of the usual "constant mesh" hum. Owing to the ease of gear-changing and the fact that noise is nonexistent a higher top gear than normal can be employed ; this, of course, is conducive to high maximum speed, fuel economy and quiet running.

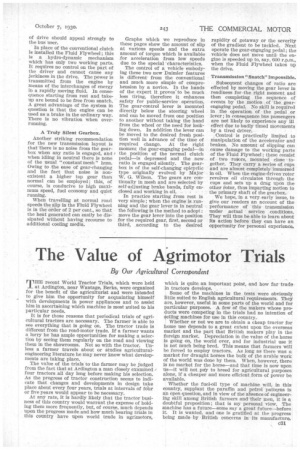

When travelling at normal road speeds the slip in the Fluid Flywheel is in the order of 2 per cent., so that the heat generated can easily be dissipated without having recourse to additional cooling media. Graphs which we reproduce in these pages show the amount of slip at various speeds and the extra amount of torque which is available for acceleration from low speeds due to the special ' characteristics.

The control of a vehicle embodying these two new Daimler features is differentfrom the conventional and much more simple of comprehension by a novice. In the hands of the expert it proves' to be much less tiring, therefore it enhances safety for public-service operation. The gear-control lever is mounted directly below the steering wheel and can be moved from one position to another without taking the hand from the wheel or the need for looking down. In addition the lever can be moved to the desired fresh position well in advance of the time of required change. At the right moment the gear-engaging pedal—in the position of the normal clutch pedal—is depressed and the new ratio is engaged silently. The gearbox is of the self-changing epicyclic type originally evolved by Major W. G. Wilson. The gears are continually in mesh and are selected by self-adjusting brake bands, fully en

closed and working in oil. .

In practice starting from rest is very simple ; when the engine is running and the gear lever is in neutral the following is the method to adopt : move the gear lever into the position for the required gear, first, second or third, according to the desired

rapidity of getaway, or the severity of the gradient to be tackled. Next operate the gear-engaging pedal; the vehicle does not move until the engine is speeded up to, say, 600 r.p.m., when the Fluid Flywheel takes up the drive.

Transmission" Snatch" Impossible.

Subsequent changes of ratio are effected by moving the gear lever in rea.diaess for -the right moment and then completing the sequence of events by the motion of the gearengaging pedal. No skill is required in the operation of the pedal or lever ; in consequence bus passengers are not likely to experience any ill effect due to badly timed movements by a tired driver.

,Control is practically limited to manipulation of the accelerator and brakes. No amount of slipping can cause damage to the working parts of the Fluid Flywheel; these consist of.. two roOors, mounted close together. They carry a series of cups and are almost completely immersed in oil. When the engine-driven rotor revolves oil circulates through the cups and sets up a drag upon the other fotor, thus imparting motion to the primary shaft of the gearbox..

We hope, in a very.early issue, to give our readers an account of the performance of this transmission under actual service conditions. They will thus be able to learn about Its action before they can have an opportunity for personal experience.