B.T.C. Ain

Page 92

Page 93

If you've noticed an error in this article please click here to report it so we can fix it.

it QUICKER

HANDLING

Freight Transport Exhibition Emphasizes Increased Use by B.R.S. of Special Vehicles

S0 far as the trader and industrialist arc concerned, the essence of an efficient freight transport service lies in the door-todoor factor. It is a service which the independent haulier has long been able to provide and its features include convenience, the minimum of handling, saving of time and lower costs.

Recent -developments within the structure of British Road Services, however, show clearly that the British Transport Commission are prepared to spend a good deal of money to get the business. In this, B.R.S. are in step with British Railways, which, with their rail wagons and road vehicles, are making notable attempts to offer a throughout service in the fields in which tail must predominate.

The lines on which the B.T.C. are thinking were made abundantly clear at the freight transport exhibition which they staged at Battersea Wharf Depot, London, this week. Although most of the exhibits were of new railway equipment, particularly of. containers and special-purpose wagons, B.R.S. were strongly represented. Here, again, the emphasis was on specialization—the availability of the right vehicle for a particular purpose.

Of a total fleet of some 16,000 B.R.S. vehicles, only 7,750 are assigned to general haulage. The remainder are for outsize traffics (Pickfords), parcels, meat and for contract hire.

Throughout the exhibition, emphasis was placed on speedy handling, especially in the loading and unloading of railway wagons. There were frequent demonstrations and in most of them it was the driving of the fork-lift truck and the 7+ton Rapier mobile crane which excited as much interest as the load itself.

The fork truck in use was the SD Freightlifter, complete with British Railways' modifications. This machine, of which 50 are in use in depots throughout the B.R. system, will lift more than 8 tons as a fork lift, can be converted into a 6,1--ton mobile crane, and with a lifting frame, can handle containers up to 71 tons. It will also serve as a searcher crane for removing articles weighing up to a ton from the corners of covered wagons, and can be driven from depot to depot on the road.

There are alternative driving positions, both enclosed, at front and rear, and driver fatigue is markedly reduced by the use of hydraulic booster steering. The power unit is a Perkins P6 65 b.h.p. oil engine.

The Penman ramp is being experimentally used. This simple device is designed to ease the task of transferring containers between rail and road vehicles in the railway siding. It consists of two raised rails with inclined end sections which are set up on each side of the railway line. The containers are provided with pull-out skids at each corner and these engage with the guide rails as the vehicle moves between them.

Easy Transfer Thus, a railway conflat wagon can he driven between the guide rails, the skids are rolled up the incline and the container is left in the elevated position while the wagon is removed and replaced by the lorry. In the reverse motion, a hingedt flap under the container engages with a batten on the floor of the vehicle, the motion of which draws the container gently downwards on to the platform.

Perhaps the greatest factor in reducing handling costs is the use of the unit load, either in a container or on a pallet. Containers are available in a large number of types and sizes, for both rail and road use. They are, howeVer, expensive consignments when travelling empty. An effective solution of this problem lies in the collapsible container, an example of which has been developed for the railways by T.I. (Group Services), Ltd.

It is largely of light alloy and in the erect state has a capacity of 4 tons, or 648 cu. ft. It measures overall 16 ft. long, 7 ft. 5-1in. wide and 7 ft. high, and has a tare weight of 1 ton 11 cwt. in prototype form. It is intended to reduce this to 27 cwt. by using light-metal castings and extrusions where mild Steel is embodied at present.

The collapsing drill is simple. Inside the end door there is a roof-mounted lever, actuation of which pushes the body ends outwards, freeing spigots and with

drawing interlocking bars in the body side collapsing cams. Movement of levers on the exterior of the body sides then breaks the sides at the horizontal hinges, allowing them to jack-knife inwards.

In the collapsed position, the container is folded within its own dimensions and is ready for stacking. Four chain sling attachments are provided for raising and lowering with crane or fork lift.

Flexibility of the pallet system was demonstrated by the Tr-pad shown on a Leyland Octopus rigid eight-wheeler. This arrangement was fully described in The Commercial Motor on August 1.

It consists of a 24-ft. platform in three interchangeable sections. Each 8-ft. pallet is capable of carrying 5 tons and can be handled by fork truck. Each section is located on the underfrarne by two pyramid projections and transverse triangular members.

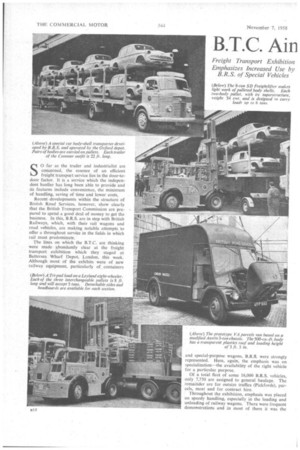

An unusual car-body transporter has been evolved by B.R.S. and is in use by their Oxford depot. In constant service on the run to Birmingham, the outfit consists of a Commer ES2, tractor, with two 22-ft. trailers. Each trailer is a two-tier structure carrying four body, shells on pallets; loading is by heavy-duty fork truck.

• The more familiar type of car transporter was also shown at Battersea. This model is a double-deck:er, in which cars

are run on to the upper stage, which can be raised and lowered by hydraulic rams. Pivoted at front and rear, the deck can be raised from ground level smoothly and rapidly into the travelling position. Four complete vehicles can be carried.

As yet in prototype form, the VA 3-ton parcels van based on the Austin 11-ft. 6-in, wheelbase forward-control chassis, with 3.4-litre B.M.C. oil engine, represents another B.R.S. development. This specially designed van was also described in The Commercial Motor on August 1. Although basically a forwardcontrol vehicle, the steering-column rake has been altered and the pedals set back to give an unobstructed passage from cab to body proper.

A deep windscreen and short bonnet line give excellent vision forward when parking, and a window in the bulkhead behind the driver gives almost as good a view to the rear. There is no passenger's seat and entry from both sides is practically unobstructed. The 500-cu.-ft. body has a full-width transparent plastics roof and a rear loading height of 3 ft. 3 in.

The B.R.S. section at the exhibition was completed by displays of coachwork of more standard pattern. They included a 4,000-gal. five-compartment petrol tank on an A.E.C. Mammoth Major chassis,

Bonallack 10-ton bulk grain carrier on a Leyland Comet and an 8-ton meat trolley.