Lively and Easy :o Service

Page 76

Page 77

Page 78

If you've noticed an error in this article please click here to report it so we can fix it.

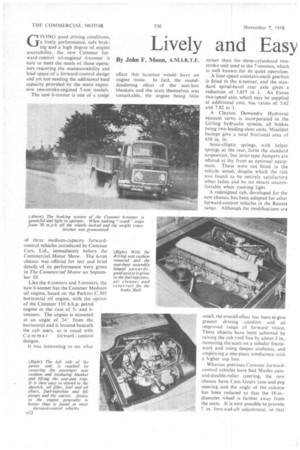

New Commer Forward-control Range of 4-, 5-, and 6-tonners Has Brisk Performance By John F. Moon, A.M.I.R.T.E. GIVING good driving conditions, . a lively performance, safe braking and a high degree of engine accessibility, the new Commer forward-control oil-engined 6-tonner is sure to meet the needs of those operators requiring the manceuvrability and bad space of a forward-control design and yet not needing the additional load capacity provided by the more expensive two-stroke-engined 7-ton models. The new 6-tonner is one of a range of three medium-capacity forwardcontrol vehicles introduced by Commer Cars, Ltd., immediately before the Commercial Motor Show. The 6-ton chassis was offered for test and brief details of its performance were given in The Commercial Motor on September 19.

Like the 4-tonners and 5-tonners, the new 6-tonner has the Commer Medium oil engine, based on the Perkins C.305 horizontal oil engine, with the optionof the Commer 110 b.h.p. petrol.

engine in the case of 5and 6tonners. The engine is mounted at an angle of 24° from the horizontal and is located beneath the cab seats, as is usual with Commer forward control designs.

It was interesting to see what effect this location would have on engine noise. In fact, the sounddeadening effect of the seat-box blankets and the seats themselves was remarkable, the engine being little noiser than the three-cylindered twostroke unit used in the 7-tonners, which is well known for its quiet operation.

A four-speed constant-mesh gearbox is fitted in the 6-tonner, and the standard spiral-bevel rear axle gives a reduction of 5.857 to I. An Eaton two-speed axle, which may be supplied at additional cost, has ratios of 5.62 and 7.82 to I.

A Clayton Dewandre Hydrovac vacuum servo is incorporated in the Girling hydraulic system, all brakes being two-leading-shoe units. Moulded facings give a total frictional area of 438 sq. in.

Semi-elliptic springs, with helper springs at the rear, form the standard suspension, but lever-type dampers are offered at the front as optional equipment. These were not fitted to the vehicle tested, despite which the ride was found to be entirely. satisfactory when laden and by no means uncomfortable when running light.

A redesigned cab, developed for the new chassis, has been adopted for other forward-control vehicles in the Rootes range.. Although the modifications are

small, the overall effect has been to give greater driving comfort and an improved range of forward vision. These objects have been achieved by raising the cab roof line by about 3 in., mounting the seats on a tubular framework and using deeper cushions, and employing a one-piece windscreen with a higher top line.

Whereas previous Commer forwardcontrol vehicles have had Marles camand-double-roller steering, the new chassis have Cam Gears cam-and-peg steering and the angle of the column has been reduced so that the 18-in.diameter wheel is farther away from the seats. It is now possible to provide 7 in. fore-and-aft adjustment, so that drivers of all shapes and sizes can be suited..

Additionally, there is 2 in. vertical adjustment, although the adjustment mechanism is not particularly easy to operate and can certainly not be worked while the vehicle is on the move, which possibly makes for safety.

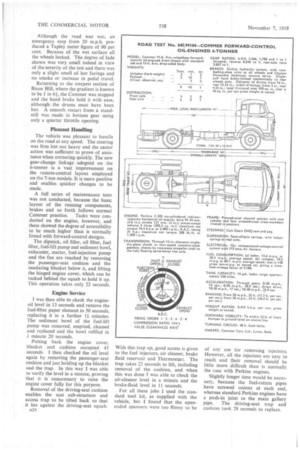

Carrying a test toad consisting of small concrete blocks which totalled 5 tons 19+ cwt., the 6-tonner was tested at a 'gross weight of 9 tons 101 cwt. The payload was evenly distributed throughout the length of the body and the weight distribution between front and rear axles was nearly in the ideal ratio of 1: 2.

Wheels Lock

Using a level stretch of the North Orbital Road, in the Hatfield area, braking and acceleration tests were

conducted first. When making fullpressure stops from both 20 m.p.h. and 30 m.p.h. all the wheels locked and on each occasion the Tapley meter showed that the maximum deceleration had exceeded 100 per cent.

There was little noticeable lag in the braking system, so the difference between maximum and average deceleration rates would be accounted for almost solely by the distance for which the wheels were locked. The hand brake showed exceptional efficiency, an. average reading of 54.75 per cent. being obtained from 20 m.p.h. Without excessive effort on the lever. During the hand-brake tests the near-side rear wheel locked.

Using second, third and top gears, rapid acceleration was achieved from a standstill up to 30 m.p.h. and the direct-drive times between 10 m.p.h. and 30 m.p.h. were good. The engine and transmission showed no signs of roughness when pulling away in top gear from 10 m.p.h. during the second series of tests.

Fuel-consumption figures were taken over the six-mile undulating circuit between Barton and Clophill normally employed on Commer tests. For the first laden test I drove, and, despite three stops, the course was completed at an average speed of 27.5 m.p.h., the fuel-consumption rate being 15.3 m.p.g., as shown by the test tank.

Alan Hargreaves, of Commer Cars, Ltd., drove for the second run and had to use the gears a little less, with the result that 1/32 of a pint less fuel was used, giving a rate of 15.6 m.p.g., and time was saved, the average speed being 28.3 m.p.h. Later in the day the course was retraced with the test weights removed and on this occasion I obtained 19.2 m.p.g. at an average speed of 30.7 m.p.h. All the figures are reasonable for an indirect-injection oil engine. although it is likely that greater economy would have been shown had an Eaton two-speed axle been fitted.

Hill-climbing tests were made in an ambient temperature of 61° F. Bison Hill, + mile long and having an average gradient of 1 in 10-1, was used.

Good Cooling Because of the long cranked filler neck necessitated by the low-slung radiator it was impossible to take the temperatures of the water in the header tank before and after the climb. but the temperature of the water the top of the neck rose from 149° F. to 162° F. during the ascent, which occupied the surprisingly short time ot 4 minutes 23 seconds. The low temperature rise served to indicate that the cooling system has ample capacity for prolonged hill-climbing in ambient temperatures of at least 100° F., additional latitude being given by the pressurizing of the system to 4 psi.

The minimum speed during the climb was 6 m.p.h. and bottom gc:tr was engaged for just over a minute.

For the fade test the 6-tonner

coasted down the hill in neutral, usjii,2, the foot brake to keep the speed &my. to 20 m.p.h. This test lasted 2+ min. and approximately 40 sec. of this time was spent with top gear engaged and full throttle applied to compensate for the reduced gradient towards the bottom of the hill.

Although the road was wet, an emergency stop from 20 m.p.h. produced a Tapley meter figure of 80 per cent. Because of the wet surface all the wheels locked. The degree of fade shown was very small indeed in view of the severity of the test and there was only a slight smell of hot facings and no smoke or increase in pedal travel.

Returning to the steepest section of Bison Hill, where the gradient is known to be 1 in 61, the Commer was stopped and the hand brake held it with ease, although, the drums must have been hot. A smooth restart from a standstill was made in bottom gear using only a quarter throttle opening.

Pleasant Handling

The vehicle was pleasant to handle on the road at any speed. The steering was firm but not heavy and the castor action was sufficient to prove of assistance when cornering quickly. The new gear-change linkage adopted on the 6-tonner is a vast improvement on the remote-control layout employed on the 7-ton models. It is more positive and enables quicker changes to be made.

A full series of maintenance tests was not conducted, because the basic layout of the running components, brakes and so forth follows normal Commer practice. Tasks were conducted on the engine, however, and these showed the degree of accessibility to be much higher than is normally found with forward-control designs.

The dipstick, oil filler, oil filter, fuel fitter, fuel-lift pump and sediment bowl, exhauster, starter, fuel-injection pump and the fan are reached by removing the passenger-seat cushion and the insulating blanket below it, and lifting the hinged engine cover, which can be tucked behind the squab to hold it up. This operation takes only 22 seconds.

Engine Service

I was then able to check the engineoil level in 13 seconds and remove the fuel-filter paper element in 50 seconds, replacing it in a further 11 minutes. The sediment bowl of the fuel-lift pump was removed, emptied, cleaned and replaced and the bowl refilled in I minute 20 seconds.

Putting back the engine cover, blanket and cushion occupied 45 seconds. I then checked the oil level again by removing the passenger-seat cushion and just holding up the blanket and the trap. In this way I was able to verify the level in a minute, proving that it is unnecessary to raise the engine cover fully for this purpose.

Removal of the driving-seat cushion enables the seat sub-structure and access trap to be tilted back so that it lies against the driving-seat squab.

o24 With this trap up, good access is given to the fuel injectors, air cleaner, brake fluid reservoir and Thermostart. The trap takes 22 seconds to lift, including removal of the cushion, and when this was done I was able to check the air-cleaner level in a minute and the brake-fluid level in 11 seconds.

For all these jobs I used the standard tool kit, as supplied with the vehicle, but I found that the openended spanners were too flimsy to be of any use for removing injectors. However, all the injectors are easy to reach and their removal should be little more difficult than is normally the case with Perkins engines.

Slightly longer time would be necessary, because the fuel-return pipes have screwed unions at each end, whereas standard Perkins engines have a push-in joint to the main gallery pipe. The driving-seat trap and cushion took 28 seconds to replace.