For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZ E" OF TEN SHILLINGS is awarded each week to the sender of the best letter which we publish on this page; all others are paid for at the rate of a penny a line, with an allowance for photographs. All notes arc edited before being published. Mention. your employer's name, in confidence, as evidence of good faith. Address, .D., M. and F., "The Cotinnercial Motor," .7-15, gosebery Avenue, London, E. C. 1.

Lamps Alight.

On Saturday, the 9th November, light your lamps at 4.49 in London, 5.15 in Edinburght 4.43 in Newcastle, 4.54 in Liverpool, 4.53 in Birmingham, 5.0 in Bristol, and 5.39 in Dublin.

An Ingenious Steering Gear Repair.

The sender of the following communication has been awarded the Ws. prize this week.

[1914] " A.S." (Bradford) writes :—" A short time ago I had the pleasure of describing for the benefit of your readers the good service which had been rendered by a 31--ton.. Seabrook chassis, and I also gave a few notes about lubrication. The chassis is still doing well, and has only had one overhaul in three

years. Accidents, however, will happen, and the relation of one which occurred recently in connection with this wagon will no doubt be of interest, particularly as the detail affected, the steering gear tie rod, is of similar design and construction on a large number of chassis of American make, so that other, readers may derive useful assistance from this description.

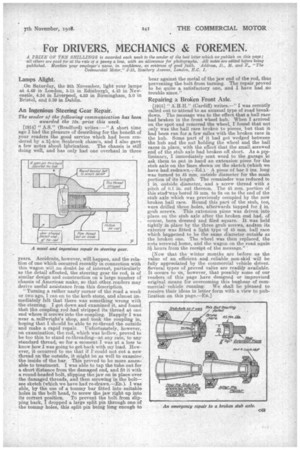

"Turning a rather nasty' corner of the road a week or two ago, I ran on to the kerb stone, and almost immediately felt that there was something wrong with the steering. I got down and examined it, and found that the coupling rod had stripped its thread at one end where it screws into the coupling. Happily I was near a_ millwright's shop, and took the coupling in, hoping that I should be able to re-thread the outside and make a rapid repair_ Unfortunately, however, on examination, the rod, which was hollow, proved to be too thin to stand re-threading—at any rate, to any standard thread, no for a moment I was at a loss to know how I was going to get back with my load. However, it occurred to me that if r could not cut a new thread on the outside, it might be as *ell to examine the inside of the bar. This proved to be more amenable to treatment. I was able to tap the tube out for a short distance from the damaged end, and fit it with a round-headed bolt, slipping the jaw on in place over the damaged threads, and then screwing in the bolt— see sketch (which we have had re-drawn.—En.). I WM able, by the use of a tommy bar fitted into suitable holes in the bolt head, to screw the jaw right up into its correct position. To prevent the bolt. from slipping back, I dropped a large split pin through one of the tommy holes, this split pin being long enough to

bear against the metal of the jaw end of the rod, thus preventing the bolt from turning. The repair proved to be quite a satisfactory one, and I have had no trouble since."

Repairing a Broken Front Axle.

[1915] " A.H.II." (Cardiff) writes.—" I was recently called out to atten&to an unusual type of road breakdown. The message was to the effect that a ball race had broken in the front wheel hub. When I arrived on the spot and removed the wheel, .I found that not only was the ball race broken to pieces, but that it had been run for a few miles with the broken race in the hub. Some part of it had got wedged between the hub and the nut holding the wheel and the ball races in place, with the effect that the small screwed end of the stub axle had broken off short. As a preliminary, I immediately sent word to the garage le ask them to put in hand an extension piece for the stub axle on the lines shown on the sketch (which we have had redrawn..---Ed.). A piece of bat 3 ins, long was turned to 45 rum. outside diameter for the main portion of its length. The remainder was reduced to 1 in. outside diameter, and a screw thread with a pitch of 0.1 in. cut thereon. The 45 mm. portion of this stud-was bored 35 mm. to fit on to the end of the stub axle -which was previously occupied by the now . broken ball race_ Round this part of the stub, too, were drilled three holes, afterwards tapped for I in.

• grub screws_ This extension piece was driven into place on the stub axle after the broken end had, of course, been dressed and filed square. It was held tightly in place by the three grub screws, andton its exterior was fitted a light type 'of 45 mm. ball race which happened to be the same diameter outside as the broken one. The wheel was then replaced, the nuts screwed home, and the wagon on the road again 3i. hours from the receipt of the message."

[Now that the winter months are before us the value of an efficient and reliable non-skid will be fully appreciated by the commercial vehicle driver. Several types of proved value are readily available. It occurs to us, however, that possibly some of our readers of this page have designed or improvised original means for overcoming this bugbear of commercial vehicle running. We shall be pleased to receive their ideas in letter form with a view to publication on this page.—En.]