Good-bye to the Plough Horse.

Page 8

Page 9

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

An Exclusive Account of a Remarkable Demonstration of a Self-contained Motor-propelled Plough, costing £75 only, which can Travel Alone over the Land and do its Allotted Work Accurately.

In the course of the editorial routine of this journal, as may imagined, we are constantly being brought into touch with new phases of application of the motor to all kinds of special industrial uses. We can safely say, however, that in very few cases have we been so interested in a series of tests as we were one day last week when we witnessed, arid assisted at, a special series of trials of an entirely new form of motor plough.

Our readers will readily concede that we have not, in the past, been hopeful of the industrial future of the horse, however much he may have appealed to us from a sentimental point of view. The plough horse was, perhaps, almost the last of his race which one would have expected to have been defeated on economic and practical grounds. The symbol of peaceful occupation, and, as a rule, of ultra-conservative methods, he has shared with the bullock employment in front of the plough-share for many hundreds of years in all parts of the world. To-day we have to record our impression that his occupation in this respect is seriously threatened.

The Problem of the Plough.

Ploughing by motor is, of course, not a new thing by any means. Many clever minds have been at work on the problems connected therewith for a number of years past, and a considerable measure of success has attended the efforts of designers and constructors in this respect. To a certain extent, however, there has been a tendency, with one or two notable exceptions, to specialize in. regard to the heavier type of independent tractor or of cable-hauled ploughs operated by stationary mechanism at the ends of the furrows.

The recently-completed trials at Reims and, before that, at Bourges, showed us that there is now a tendency for constructors to experiment with the self-contained plough. Some examples of these recent tests were with the self-contained variety, in which the ma

chine, with its ploughs, both of the ordinary and rotary types, attached to it, travelled over the ground en bloc. That this was a move in the right direction many interested people have conceded.

The Need for a Smaller Type.

Those who read our columns carefully may remember that we have, on a number of occasions in the past, pleaded for the immediate development of a smaller type of machine than. those which have already been tested—for a plough or cultivator, in short, which should be suited for use as well between trees in orchards and in vineyards, and between the rows of root and ground crops in market gardeners' plantations, as in the stubble of the open field. Such a machine, we have urged, must be cheap to purchase, and must yield operating costs of a favourable nature in comparison with other mechanical means already well developed. This, we felt, was a problem to which our designers in this country might well turn their attention. A Design Evolved from Know

ledge.

It was therefore with pleasurable anticipation that we journeyed to Evesham last week to see for ourselves the result of the labours of Messrs. Wyles Bros., of 48, Windsor Road, in that town, who have now, after a very considerable period of hard practical experiment, evolved two small types of machines which are full of interest, and with which criticism may confidently be challenged. Last week we saw both the Wyles motor plough and the cultivator, and we were very considerably impressed with both machines. They will undoubtedly create a. very great deal of interest amongst agriculturists in this and other countries, as they are so obviously the result of a keen and perceptive knowledge of farmers' and market gardeners' requirements. Already, we are permitted to say, one of the most important manufacturers of agricultural plant in this country is in negotiation with Messrs. Wyles Bros. for the manufacture, on a large scale, of these machines, and that in itself is sufficient, we consider, to set the seal of approval upon both models.

"It's so Simple."

The simplicity of the designs of both the 'plough and the cultivator is remarkable, and the machines are of that type of which one so readily says, "Why hasn't it been done before " They owe their concep

tion and development to Mr. Albert Wyles, Junr., who was trained as an engineer, but who for reasons of health had temporarily to abandon that profession and to engage in market gardening. This latter, however, was not much to his taste, and it was not long before. he set to work to try and do some of his tasks by machinery. The Wyles motor plough, as well as the cultivator, are therefore the results of a combination of practical knowledge on both sides of the problem. That is undoubtedly the reason why such success has been achieved with so simple a machine.

The Adjustable Wheel Height.

Early experiments in regard to ploughing were made by Mr. Wyles with a machine which had a simple motor drive by clutch, arid spurgear reduction to a live axle, with a differential gear. These experiments were partially successful, but considerable trouble was encountered owing to the difficulty of steering the machine while both wheels were mounted on a common axle. Many ways out of the difficulty were considered, and some were put to practical tests, but the final solution was reached in the method that has now been permanently adopted, a method which has wisely been patented very fully. This new design permits the vertical relative adjustment of the two driving wheels independently of each other, alteration of height in the two wheels being effected, in the machine which we inspected, by mounting them on short radius brackets which are pivoted around the spur driving pinion& The spur wheels, into which these engage, necessarily follow the radius arms round, and so maintain constant mesh depth in engagement with their respective pinions. These radius arms are moved up and down by a simple arrangement of levers, one on each side of the machine, the operating handles of which are situated close to the steering handles of the plough proper. The vertical adjustment of the two driving wheels may be rapidly and simply effected, to any extent desired, while the machine is at work. It is this adjustable device, together with the skilful balancing of the mechanism of the little machine, which has solved the problem of automatically cutting a straight furrow with this little machine.

But Little Mechanism.

Of the other mechanism there is little to say. On the plough, a small water-cooled engine, which in future examples is always to be magneto-ignited, drives through a simple metal cone clutch, a chain, and two spur-gear reductions to the driving wheels proper. The cultivator is arranged on much the same lines, with the exception that it has not been found necessary to abandon the concentric mounting of the two driving wheels on the axle. The engines are governed in both cases, so that nothing is left for an attendant to operate except the clutch on both models, with the exception that on the plough there is, of course, the adjustment of the two driving wheels also to consider.

The Pioneer Construction.

Successful as these two first examples have been—and their tests have been most strenuous at the hands of practical agriculturists of all kinds, they have been built throughout by Mr. Wyles without the chance to pick and choose very much with regard to the material which he has embodied. Nevertheless, he tells us, the alterations which he will make when the machines, as they soon will be, are made in large numbers, will be very few indeed. The radiator is obviously not quite of the type which will be adopted finally, but this is a small detail.

For Scuffling or Skimming.

The frame of each machine is so constructed that any of the ordinary agricultural tools for scuffling, skimming, hoeing, cultivating and drilling, may be bolted direct to the main frame behind the driving wheels, so that the farmer is not. asked to use special tools but can employ those to which he is always accustomed.

There is no more to be said with regard to the design. Our readers will be able readily to gather an impression of the machines in question from the excellent photographs which we are able to reproduce, and which were taken specially for this journal last week.

Tests under Severe Conditions.

When we decided to make our tests, the whole of the Evesham district was almost a sheet of water. The floods were up, and it was pouring with rain. Arriving at a field several miles from the town, a heap of sodden sacking in the middle of the field was designated as our objective. Plodding across the sodden ground, and with apologies for not having better material for an exhibition of the machine's powers available, Mr. Wyles flicked off the sacking, tickled the carburetter' and with a couple of turns of the handle the plough was ready for operations. We were told that, in order that these early trials may be as useful as possible, the machines are not taken indoors, but. are left about in the fields in the neglected way which is common to most agricultural machinery! Cutting to a depth of between 5A in. and 6 in., the firSt furrow was split open with both wheels adjusted to the same level, and the machine was st cored in the ordinary way in order to cut straight. On its return

trip the share was tilted out of the ground, the machine was easily swung round about its centre, and, with practically no headland remaining, the offside wheel was regulated down into the furrow which had already been cut., and the machine was started on its return journey. This was repeated without a hitch several times, while Mr. Wyles demonstrated the manner in which the peculiar sus pension of the machine rendered ploughing such an easy matter with it.

Ploughing Without Man or Horse. A 4 h.p. engine enabled a furrow nearly 6 in. deep to be cut at a speed well over 3 m.p.h. When a few furrows had been cut, Mr. Wyles said, "Now we will show you how the machine can look after itself. I will start it on its next furrow, and it will plough it entirely unattended." Seldom have we witnessed a test of quite so striking a character. The manner in which the little plough went straight down the field, with its lower wheel running as in a rail in the furrow that had been previously cut, was almost uncanny ; from headland to headland it went without a hitch. When it came across a little bit of stubborn ground, whichever wheel was getting less grip than the other slipped slightly, but the share was kept up to its work and gradually it worried its way through, with almost human pertinacity, and without any deviation to the right or left, be it. noted, in spite of the sodden ground and the difficulty of adhesion. No horse could have ploughed under such sodden conditions.

Crossing the Field Alone.

Both wheels are fitted with diagonal adhesion strips, and in place of a differential there is a simple free-wheel ratchet device inserted inside each driving pinion. Arriving at each headland, the machine was turned ; it then came back up the field in the same way, quite unattended. So the whole fieid might well have been ploughed, thus opening up a vista of a large area being ploughed by a number of these small machines, with just a couple of men at the headlands ready to turn them when they arrived. Demonstrations of the ease with which the machine could be tilted to just the right angle by means of the wheels, in order to correct any tendency to get away to the right or to the left, and of the ease of turning round at headlands, concluded our experiments with the Wyles motor plough.

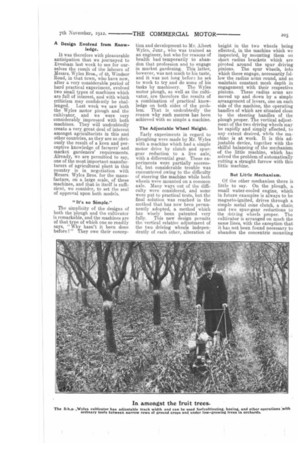

In Amongst the Fruit Trees.

We then drove to the other side of Eveshaan, and found a still smaller mael'ine, which is primarily designed for use as a cultivator, amongst root crops and orchards. Some of our illustrations show the machine thus employed. In this instance, of course, it is necessary to steer the machine. Its driving wheels are adjustable laterally, so that it is possible to use cultivator or tine blades in all sorts of hitherto inaccessible places, over ground on which manual digging, at about 50s. per acre, has previously been the only possible means of operation. Straddled across onion beds or rows of gilly flowers or the many other crops which are sown, in this and many other districts, at the foot of the fruit trees, it was possible to cut the soil in all the narrow channels between the crops. Fifteen in. width overall is the limit in which the Wyles cultivator can be used. Horses, of course, are impossible under such conditions, as also is any other known means of mechanical cultivation, not only on account of the narrowness of the

track but also because of the lowgrowing fruit-tree branches, In .Australia, Mr. Wyles senr. tells us, orchard trees are being grown with their branches much lower than is the practice at present in England, and therefore the difficulties of operation beneath them are increased with all means that have been hitherto employed.

6-cwt. for a Single Furrow.

We may, perhaps, now briefly refer to some of the perfectly

obvious advantages which these new machines offer. First of all in regard to the motor plough. It will be seen that the great factor making for economy is the reduction of dead weight in the operating mechanism. The whole singlefurrow self-propelled plough weighs just over 6 cwt. There is no fuel tax to pay, and it will plough, Toughly, an acre and a half a d,ay. With a 9 in. width of furrow, this calls for 18 miles of travel. The engine, we have said, is of only Lhh.p., and this consumes well mder three gallons in the day, so at the cost of fuel should not be ore than 35. all told, on a gen rsoils estimate. A man will cost . a any. and interest on capital, depreciation and small stores may be another 35. a day, making 9s, for he day's work of an acre and a talf, ploughed 6 in. deep.

Remarkable Economy. Saving 10s. an Acre.

In the Evesham district the " Gee-oh" method of horseploughing, that is, with two horses s breast, is seldom or never used. As a rule, three horses tandem ave to be employed in that part of the country. It must be rememered that horses . are never . able t exert their full power on rough

ground, and when it is wet their capacity is still further considerably reduced. The cost of horseploughing in the Evesham district varies from 13s. to as much as Li per acre, so that the fact that the new method beats horses hollow on cost needs no further elaboration. The two-furrow Wyles plough should operate at the rate of 10s. a day, and of course will do twice the amount of work, tic, that the cost per acre will be reduced to about 3s. 4d.

Up Against the Horse.

In contrast with horses, there is no padding of the sub-soil; the effect of horses' hooves in this respect is only too well realized by advanced agriculturalists. The intensity of pressure from the average horse's hoof is something like 50 lb. per sq. in., -whilst that from either wheel of the Wyles plough is probably under 10 a per sq. in. This is a consideration

i which s of vital importance.

Plough horses, as a rule, are fed at 5 am. They must then rest from half an hour to an hour, and they generally start work in the fields at from 7 to 7.30 a.m. They will go on working until 3.30, when they are tired out. That is approximately eight hours for the field, and afterwards the ploughman has to feed and bed down the animals. The motor-plough, of course, requires no preparation and no subsequent attention. It can start straightaway in the morning, and can be left to its own devices directly the day's work is done.

Compared with the Tractor.

Now, with regard to a comparison between tractor-ploughing and the new method, first. of all there is the great consideration of relative weights. With a Wyles plough this works out at a maximum of 6 cwt. per furrow, whilst with an average tractor and a gang plough the weight is in the neighbourhood of one ton per furrow. The relative amount of dead weight which has to be hauled about to do the same work is obvious. The saving at headlands in regard to the little machine has, of course, no need of demonstration ; the tractor is invariably awkward in this respect, whereas the Wyles machine can, as we have already recorded, be swung round on its driving wheels, about which the weight is balanced. A tractor requires a man to drive it, and there must also be a man in charge of the gang plough. As a rule, single or double-furrow ploughs only are found to be most useful in this country ; abroad and in the Colonies the larger machines and tractors, of course, have matters much their own way.

First Cost per Furrow.

With regard to the initial cost, the small self-contained machine will be something in the nature of £60 per furrow, whilst the larger tractor plant, as a rule, will cost something between 2100 and 2150 per furrow. Something approaching 50 per cent. of the power of a tractor is absorbed in hauling its own dead weight over the rough ground. Mr. Wyles is proud of his claim that with his small machine he can plough a furrow 6 in. deep in heavy ground with 4 h.p., and he is of opinion that no other plant so far produced can approach this. We ask, can the horse ?

Summing Up.

In conclusion, we may summarize the advantages of these new machines as follow :—Their low gross weight, and consequently their low proportion of inoperative weight ; their handiness in operation I lack of need for skilled use their ability to go over marshy and bad ground where heavy plant dare not venture their low first cost, and their low cost of operation. Both the plough and the cultivator, of course, have their specific uses, but in general the advantages quoted above apply to both types of machines. Very many farmers are purchasing small stationary plant. The new Wvles machines are to have belt pulleys, so that .for a few pounds extra a farmer may have a combined plough, cultivator and stationary power plant. We welcome their introduction as opening a new era in connection with the cultivation of land as we find it in this country. We consider that Messrs. Wyles Bras. have tackled the problem from the end which we have persistently advocated, and wewish them every success in connection with it..