Commer make a Thn Cylindered Oil Engir

Page 52

Page 53

Page 54

Page 55

Page 56

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

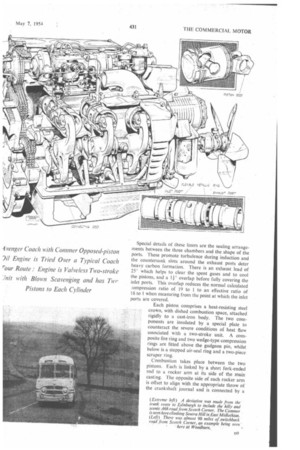

4 venger Coach with Commer Opposed-piston 7i1 Engine is Tried Over a Typical Coach rour Route : Engine is Valveless Two-stroke init with Blown Scavenging and has Twe

Pistons to Each Cylinder By Laurence J. Cotton,

M.1.R.T.E.

ATHREE-CYLINDERED . horizontally opposed two-stroke oil engine with blower scavenging is now being produced in quantity by Cormier , Cars, Ltd., 'Luton, for use in the Avenger chassis and the Harrington Contender and Beadle chassisless

.' construction passenger vehicles. It is the most unconventional British-designed compression-ignition unit offered for road transport use. It has such features as two opposed pistons to each cylinder bore, no inlet or exhaust valves, and the combustion space is formed between the crowns of each pair of pistons.

Opposed forces are balanced by this method of design. providing exceptionally smooth running and retaining

good torque at moderate engine speed. At the same time, the unit is no noisier than a petrol engine and its acceleration is as good. I formed these impressions during an 800-mile test on an Avenger coach equipped. with the oil engine.

The engine has a 3tlin bore and 4-in, stroke for each piston, giving a .total capacity of 3.261. litres (199 Cu. in.). It develops 90 b.h.p. at 2,400 r.p.m., the governed speed, and 250 lb.-ft. torque is available at 1,200 r.p.m.

In shape, the Commer engine is almost a cube. because the crankshaft is located centrally below the horizontally disposed cylinders and each pair of pistons is connected through sturdy offset rocker arms and a pair of connecting rods to a journal, the shaft having six throws and being supported by four main bearings. The cylinder block and crankcase form a single compact iron casting and cast-iron wet cylinder liners are employed. These are sealed at the water, inlet and exhaust chests by flexible metallic lips ground on the outer diameter, thus dispensing with conventional joints.

Special details of these liners are the sealing arrangements between the three chambers and the shape of the ports. These promote turbulence during induction and the countersunk slots around the exhaust ports deter heavy carbon formation. There is an exhaust lead of 25° which helps to clear the spent gases and to cool the pistons, and a I r overlap before fully covering the inlet ports. This overlap reduces the normal calculated mmpression ratio of 19 to 1 to an effective ratio of 16 to 1 when measuring from the point at which the inlet ports are covered.

Each piston comprises a heat-resisting steel crown, with dished combustion space, attached rigidly to a cast-iron body. The two components are insulated by a special plate to counteract the severe conditions of heat flow associated with a two-stroke unit. A composite fire ring and two wedge-type compression rings are fitted above the gudgeon pin, whilst below is a stepped air-seal ring and a two-piece scraper ring.

Combustion takes place between the two pistons. Each is linked by a short fork-ended rod to a rocker arm at its side of the main casting. The opposite side of each rocker arm is offset to align with the appropriate throw of the crankshaft journal and is connected by a

second fork-ended rod to the journal bearing.

Lead-bronze bushes are used throughout the connecting-rod linkage, but the big-end bearings employ copper-lead-indium-lined shells on the pressure side and babbitt-lined shells on the other half. The main bearings have whitemetal-lined shells.

Although there are more components to the piston-crankshaft link assembly than in a • normal power unit, no camshaft, valve gear, rocker shaft or cylinder heads are required. There is an addition in the Roots-type Wade blower, which is driven through a springcushioned quill from a triplex chain at the rear of the engine to supply air, at low pressure, to a chest in the cylinder block.

Low-pressure Blower

This blower is driven at 1.8 times engine speed and supplies air at 6 p.s.i. at governed engine speed. Air is passed through a triple oil-bath cleaner and silencer before entering the blower. A partial vacuum is created in the crankcase to prevent leaks at the oil seals or joints.

A C.A.V. pneumatically governed fuel-injection pump is mounted horizontally above the main casting, between the air cleaners and injectors and driven by the triple chain. A springloaded dog drive is incorporated, with 130° of movement to prevent crankshaft contrarotation under power.

The injectors, one per cylinder, are biased by 100 towards the inlet port piston and spray in the swirl stream, instead of against it, which is customary practice. The injectors are of single-hole pattern set to operate at 140 atmospheres.

A single chain drive is provided for the geartype lubrication pump at the front, which supplies full-pressure oil to the main bearings and through drilled passageways to the crank pins and connecting-rod rocker shaft. An intermittent supply is fed through drilled holes in the piston rods, whilst further holes and pipes connect the lubricant supply to the blower unit drive, injection-pump drive, the blower and the triplex chain.

A small aluminium two-stroke exhauster is provided for the brake servo system, the connecting rod being linked to. oneof the piston rocking levers. This auxiliary is attached to the side of the main engine casting and absorbs no power after exhausting the vacuum reservoir.

Weight compares favourably with that of contemporary four-stroke compression-ignition units, the engine weighing only 997 lb. complete with all auxiliaries, including the 24-volt starter and dynamo. The Commer petrol engine, which is an alternative underfloor unit in the passenger chassis, weighs 830 lb.

Conventional mountings are employed, with Metacone units outrigged from the clutch housing, but the Commer oil engine is not directly interchangeable in existing Avenger chassis, because different front and rear bearers are used.

The silencer is a double-muffle unit arranged to be free from back pressure and has a flexible section to the exhaust pipe to compensate for engine movement. In addition, the frame brackets of the exhaust system incorporate Harrisflex bushes to prevent vibration being transmitted to the chassis and body.

Although there is a difference in the mounting arrangements between the Commer six-cylindered inclined petrol engine and the new two-stroke oiler, the power unit occupies roughly the same position in the Avenger passenger chassis, that is, approximately below the driver's seat.

Because the three-cylindered oil engine is shorter than the petrol engine, it absorbs less body floor space, which was apparent in a Plaxton 33-seat coach body of the test vehicle. The space adjacent to the driving seat, over the engine bay, was allocated to a courier seat, a low door in

DIO

a waist-high, trimmed bulkhead separating the crew from

the passengers. . .

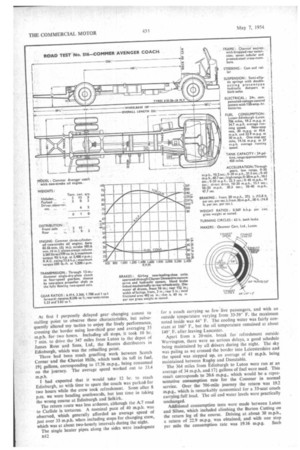

The body was 8 ft. wide and 27 ft. 6 in. long, affording comfortable seating for long-distance touring. The chassis was a standard Avenger, having the four-speed gearbox with • constant-mesh helical gears for the third ratio and vacuumservo braking, using a 6.87-in. servo motor. An Eaton twospeed axle, an optional unit, was fitted, the ratios of 5.33 and 3.83 to 1 being specially provided to mate with the engine performance and spread of the gearbox.

A Mann Egerton fuel test tank was fitted for local trials and remote-reading thermometers put into the engine top water pipe and in the base to record oil and water temperatures during a 700-mile consumption trial, staged-from Luton to Edinburgh and back.

Tested Fully Loaded

Ballast was added to bring the total weight to 8 tons 1 cwt., which allowed for the driver, courier, 33 passengers and 3 cwt. of luggage. The unladen weight of the coach, with the Plaxton body, was 5 tons 13 cwt._

All formalities, including measuring brake-shoe clearance at alt wheels and checking oil, fuel and water levels, were completed by 7.30 a.m., and 10 min. later we were heading towards the Al road and northwards to Scotland. The drivers, who took turns in chauffeuring the photographer in an accompanying car, were two Commer representatives, John F. Moon, of The Commercial Motor, and myself.

Alan HargeaVes, of the Commer experimental department, has driven the two-stroke-engined chassis over 250,000 miles and Dick Howard, the other Rootes representative, was also well versed in its characteristics. Moon and I. were the novices. Juclging by the performance of other vehicles equipped with two-stroke supercharged oil engines, • I expected that only the top end of the engine performance would be Used, and that frequent gear changes would be necessary. I also expected more than average noise from the power unit and a hearty roar from the 'straight-through" exhaust. None of these characteristics is, however, associated with the Cummer unit.

Up to about 2,100 r.p.m., the engine is quieter and certainly much smoother than the conventional four-stroke. The injection pump can be heard above all other components and the modulated blower whine can be distinguished. When changing to a lower ratio and using maximum engine revolutions, there is a marked blower rattle.

Elastic Performance

Low-speed torque down to 1,000 r.p.m. is exceptional and the characteristics are akin to those of many four-stroke oil engines. The exhaust note from inside the coach was about normal.

Alan Hargeaves, who was first driver, demonstrated the remarkable performance of the engine by averaging 36 m.p.h. in the first hour, mostly on minor roads, the A.1 route being joined about a mile south of Sandy. It took a quarter of an hour to raise the water temperature to normal working level (160° F.), but the oil-temperature rise was slower, reaching 145° F. in the first half-hour and peaking at 160° F. after two hours' hard driving. Day temperiture was 38° F.

A fuel-consumption test was run off between Stamford and Grantham, the road being mildly undulating and fairly clear for driving at 45 m.p.h. The consumption rate worked out to precisely 20 m.p.g. at 43.6 m.p.h. average speed.

This was the first indication that the Commer could combine fast travel with economy, because driving at 45 m.p.h. was not all full-throttle work. With high-fourth gear engaged, the engine is turning at a nominal 1,400 r.p.m. at 40 m.p.h., this point on the power curve providing the highest torque (250 lb./ft.) with the lowest consumption (0.38 lb./b.h.p./hr.). With the ratios provided the coach has a maximum speed of 68 m.p.h.

It is not surprising that with little hindrance on the road, 39 miles were covered in the second hour, which included a fairly slow passage through Stamford and a lowfourth-gear climb up Alconbury Hill. There were slight delays in Grantham, as there were in most of the towns along the A.1 route, but no stops exceeded a minute.

Changing drivers on the outskirts of Grantham enabled some slow-moving traffic to build up ahead and 29 miles were covered in the third hour. A race meeting at Doncaster enforced further nose-to-tail driving before and after the town, and although driving at a fair pace where conditions permitted, only 31 Miles were put by the fourth hour.

The Commer showed up well when climbing Wentbridge Hill, which has a I-in-101 gradient. There was one main change to third gear and, with the lower ratio of the axle in use, the hill was tackled in good style. John Moon, who was driving at the time, found that low-second gear gave a smooth take-up when starting from rest on the hill.

The second crew change was at Boroughbridge, where Dick Howard took control and notched up 38 miles in the next hour, which included stops totalling 2 min. It was planned that our route should leave A.I at Scotch Corner, to follow the favourite touring ground through Jedburgh and Corbridge to Edinburgh. Undoubtedly there is magnificent scenery along this route, but I was more concerned with the fuel used in almost continual hill climbing.

Arduous Territory

At first, attempts were made to record all the gradients and gears used, but with almost 90 miles of hills and dales, only those relatively few inclines requiring second gear were subsequently noted. The first time second gear was needed was on a steep incline just before West Auckland, which was soon followed b■ the descent of Bildershaw Bank.

The famous Toft Hill was climbed in lowthird, and within two miles there was a long second-gear climb at Wilton-le-Wear which raised the oil and water temperatures to 165° V. The water temperature peaked at this point, but the oil reading continued to rise slowly to 170° F. as hill followed hill. Nevertheless, an average of 33 m.p.h. was maintained between Pierccbridge and Corbridge.

My first spell of driving was from Corbridge to Edinburgh, and with 35 miles of hills before reaching the Cheviots and the Scottish border at Carter Bar I soon found that the engine pulled well at low speed. Its ability to "hang on" at 20 m.p.h. in low-fourth gear when climbing a moderate gradient was remarkable flir.4 a blown, otwo-,stroklAnakt, „the „air-ehest twessIlie ia • this siteeeigeing just,.over -I.

At first I purposely delayed gear changing almost to stalling point to observe these characteristics, but subsequently altered my tactics to enjoy the lively performance, crossing the border using low-third gear and averaging 35 m.p.h. for two hours. Including all stops, it took 10 hr. 7 min. to drive the 347 miles from Luton to the depot of James Ross and Sons, Ltd., the Rootes distributors in Edinburgh, which was the refuelling point.

There had been much gruelling work between Scotch Corner and the Cheviot Hills, which took its toll in fuel, 191 gallons, corresponding to 17.76 m.p.g., being consumed on the journey. The average speed worked out to 33.4 m.p.h.

I had expected that it would take 12 hr. to reach Edinburgh, so with time to spare the coach was parked, for two hours while the crew took refreshment. Soon after 8 p.m. we were heading southwards, but lost time in taking the wrong course at Edinburgh and Selkirk_

The return route was less arduous, although the A.7 road to Carlisle is tortuous. A nominal pace of 40 m.p.h. was observed, which generally afforded an average speed of just over 33 m.p.h. when including stops for changing crew, which was at about two-hourly intervals during the night.

The single heater pipes along the sides were inadequate Dl 2 for a coach carrying so few live passengers, and with an outside temperature varying from 33-39° F. the maximum noted inside was 44° F. The cooling water was fairly constant at 160° F., but the oil temperature remained at about 140', F. after leaving Lancaster.

Apart from a 20-min. break for refreshment outside Warrington, there were no serious delays, a good schedule being maintained by all drivers during the night. The sky was paling as we crossed the border into Leicestershire and the speed was stepped up, an average of 41 m.p.h. being maintained between Rugby and Dunstable.

The 364 miles from Edinburgh to Luton were run at an average of 34 m.p.h. and 17.",t gallons of fuel were used. This result corresponds to 20.6 m.p.g., which would be a representative consumption rate for the Commer in normal service. Over the 706-mile journey the return was 19.2 m.p.g., which is remarkably economical for a 33-seat coach carrying full load_ The oil and water levels were practically unchanged.

Additional consumption tests were made between Luton and Silsoe, which included climbing the Barton Cutting on the return leg of the course. Driving at about 30 m.p.h., a return of 22.9 m.p.g. was obtained, and with one stop per mile the consumption rate was 19.16 m.p.g. Such

results set a high standard in economy for coach or bus operation, especially as the vehicle was fully loaded.

As proof of lively performance, the time required to reach 30 m.p.h, from rest was 21.5 sec. when using the low ratio of the axle and 22.5 sec. with the higher ratio engaged. In the past I have found it impracticable to stage acceleration tests from 10 m.p.h. in top gear with a two-stroke oil engine, but it was possible with the Commer. With an air-chest pressure of 1 p.s.i. showing at 10 m.p.h., the coach pulled steadily to reach 20 m.p.h. in 15 sec. and 30 m.p.h. in 30 sec. Such top-gear acceleration is little below that of larger-engined four-stroke models.

When the brake-facing clearance was checked at the end of the Edinburgh trial no measurable wear was found at four shoes and only 0.001 in. difference was revealed on

the others. The brake tests were made without further adjustment, the stopping distances of 271 ft, from 20' m.p.h. and 58 ft. from 30 m.p.h. being indicative of the effective retardation.

Just on 800 miles' work with the coach convinced me that the Commer engine is extraordinary. It is as smooth running as most petrol engines, causes no annoyance to the passengers and can operate a high-speed schedule withou: being extravagant in fuel.