A Special and General-purpose 13-ton Trailer

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

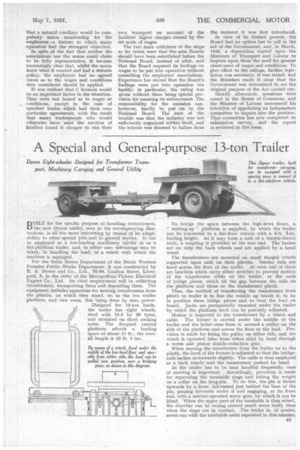

Dyson Eight-wheeler Designed for Transformer Transport, Machinery Carrying and General Utility BUILT for the specific purpose .of handling transformers, the new Dyson trailer, seen in the accompanying illustrations, is all the more interesting by reason of its adaptability to other special jobs and to general service. It can be employed as a low-loading machinery cirri6r or as a fiat-platform trailer, and, in either case, advantage may be taken, in handling the load, of a -winch with which the machine is equipped.

For the India Stores Department of the North. Western FrontierPublic. Works Department, it was constructed by R. A. Dyson and Co., Ltd., 76-80, Grafton Street, Liverpool, 8, to the order of the Metropolitan-Vickers Electrical Export Co., Ltd. Its chief employment will be collecting transformers, transporting them and depositing them. The equipment includes apparatus for moving transformers from the plinths, on which they stand, on to the low trailer platform, and vice versa, this being done by man power.

Designed for 13-ton loads, the trailer has eight wheels, shod with 10.5 by 20 tyres, and mounted on short rocking axles. The dropped central platform affords a loading space of about 11 ft.; the overall length is 23 ft. 5 ins. To bridge the space between the high-level floors, a " making-up " platform is supplied, by which the trailer can he converted to a flat-floor vehicle with a 4-ft, 5-in. loading height. As it may form a unit of a tractor-drawn train, a coupling is provided at the rear end. The brakes act on only the back wheels and are applied by a hand wheel.

The tranSformers are mounted on small flanged wheels supported upon rails on their plinths Similar rails are fixed across the floor of the trailer. At each end of these are brackets which carry either scotches to prevent motion of the transformer while on the trailer, or the ends of bridge pieces, which fill the gap between the rails on the platform and those on the transformer plinth.

Thus, the method of transferring the transformer from plinth to trailer is to line the vehicle up beside it, to fix in position these bridge pieces and to haul the load on board. Jacks are permanently mounted under the trailer by which the platform level can be precisely adjusted.

Motion is imparted to the transformer by a winch and cable. The former is carried under the middle of the trailer and the latter runs from it, around a pulley on the side of the platform and across the floor to the load. Provision is made for fixing the pulley on either side, and the winch is operated (also from either side) by hand through a worm and pinion double-reduction gear. When moving the transformer from the trailer on to the plinth, the level of the former is adjusted so that the bridge-. rails incline downwards slightly. The cable is then employed as a back steady and the transformer pushed by hand.

As the trailer has to be man handled frequently, ease of steering is important. Accordingly, provision is made for separating the turntable rings and taking the weight on a collar on the king-pin. To do this, the pin is thrust upwards by a lever, fulcrumed just behind the base of the pin, passing forwards under it and engaging, at its front end, with a ratchet-operated screw gear, by which it can be lifted. 'When the upper part of the turntable is thus raised, the drawbar can be swung around much more easily than when the rings are in contact. The trailer is, of course, never ran with the turntable units separated in this manner.