THE MERITS OF WEYMANN BODY CONSTRUCTION

Page 64

Page 65

Page 66

Page 67

If you've noticed an error in this article please click here to report it so we can fix it.

Explaining the Method of Constructien and How the Flexibility of the Framework Helps to Keep the Body Free from Reverberation and Drumming.

IT is surprising how many people there are who, although -familiar with names which are bywords of daily routine, would be surprised at their own ignorance if asked a few simple questions. Some of the most homely household -utensils, for example, are used by people who realize that the utensils actually do the work for which they are intended, but the why and wherefore of the principles embodied in the design of the articles in question are not appreciated. Few people, for instance, realize that the reason why an aluminium saucepan does not burn milk when placed over a fire is -due to the fact that the capacity for heat transference from molecule to molecule of the material is far greater in aluminium than in other common materials such as might be used for saucepans. This 'simple analogy can quite well be quoted as a preamble to a consideration of Weymann body construction. Practically everyone is conversant with the title "Weymann body," but how many fully understand what it implies? • The main principle involved in the Weymann patents has "flexibility" as the keynote. In other words, the whole structure is planned in such a manner that it will "give" when subjected to heavy road shocks or stresses caused by chassis distortion. No attempt is made to resist these powerful forces, but precautions are taken to avoid any relative movement between adjacent components. This might be stated in aslightly different way. The components which, by virtue the flexible nature of the structure must move in relation to one another, are so joined that the adjacent surfaces cannot come into. contact. The actual method of fixing will dealt with in detail later.

The march of progress in engine and chassis design has been extraordinarily rapid of late, and the modern commercial passenger vehicle now vies with the private car in so far as rapid acceleration and powerful braking are concerned.

STEEL FLITCH

C HASS IS fRAVIE Now it will be appreciated that the high speeds at which the modern coach. travels create difficulties for the coachbuilder, because that bugbear of engineers, " inertia," begins to take a controlling hand in the forces at work on both the body and the chassis.

The sponsors of the Weymann type of construction take the view that the easiest line of resistance is the best, so, discarding all attempts at obtaining rigidity, a definite effort is made to gain flexibility. To this end the Weymann principle provides seating on the chassis, whilst the body can be considered as a weatherproof shell which protects the occupants of the car from inclement weather conditions. No load is carried by the body, merely because the structure itself is -quite independent of the seating accommodation.

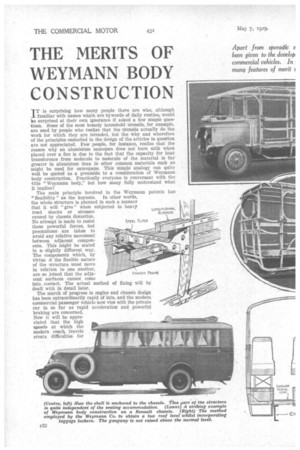

Let us now consider the constructional details of a typical Weymann body as applied to a 26-seater coach. The whole of the structure is built up in the form of cells, each of which is an entity. Each cell consists essentially of four members which are coupled together -by steel joints. The cells are bolted to the chassis through their base members and are joined together by other horizontal members at the roof line.

It would seem opportune here to give an outline of the method employed in making the joints. The framing is, of course, carried out in a high-grade hard wood. The ends of the wooden members, however, are coupled to one another by steel plates, and as all the members so joined are prevented from touching each other (merely by leaving a space between the two elements), the steel plates, form the only means of attachment. Now it is well known that steel can flex without creaking, and as there can be no friction between the timbers, the structure, although flexible, is, or should be if properly made, entirely devoid of squeaks and other similar irri tating noises.

As an indication of the care taken to avoid any possibility of noise emanating from the joints, it is interesting to note that a special greased paper IA interposed between the wood and the steel elements; thus, supposing that under excessive load slight relative movement should take place, the two contacting surfaces are perfectly lubricated.

It will be realized that if complete rigidity for the body shell ha not sought after, a structure which flexes under load can be made relatively light in weight without causing any overloading at vulnerable points. This feature of lightness is one of the main claims of the Weymann Company's design. Examination of the detail work of any Weymann botiy frame, however, shows that no stone is left unturned in the endeavour to provide proper and adequate strength where it is required. The accompanying drawings show how carefully the components have been planned to provide proper support for all parts used in the construction of the body.

How the Pillar-joints are Made.

One sketch, for example, shows the base member and the main pillar joint of one of the cells of a 26-seater coach body, and it will be seen that the base member incorporates an intOrnal steel flitch which runs throughout its length. This flitch plate is immensely strong in the direction in which it is loaded, i.e., vertically, whilst at the same time it provides proper location for the longi tudinal members in virtue of the fact that the attachment bolts for the members themselves pass through the plate. In another sketch a similar flitch plate can be seen fitted to the roof member, and this adds so much to the strength of the component that, despite its comparatively small dimensions it is amply strong.

The two drawings already referred to have really been included to show details of the cell construction. These cells are joined 1)5, a number of longitudinal members, but the only attachment to the chassis is effected through the medium of clips similar to the one shown. The floorboards are bolted to the chassis and fill up the intervening spaces between the base member for each cell. They do not touch the body frame at any point, however, there being a margin between the boards and the frame members. Naturally, the margin is not very big because the relative movement between the two elements must, even under severe conditions, be small, but sufficient space is allowed to preclude any possibility of rubbing.

The Arrangements for Locker Space.

Before passing on to a consideration of the exterior and interior finish of the bodies, reference should be made to an ingenious development in body construction which has as its object the provision of luggage lockers, without causing the gangway level to be raised. Among the illustrations will be found a drawing showing how this end is achieved. The luggage lockers are situated beneath the seats, which are raised on platforms on each side of the gangway. No inconvenience is felt by the passengers when occupying the seats because plenty of headroom is provided (for a sitting passenger), _ whilst the normal position for the gangway enables the passengers to walk erect throughout the whole length of the vehicle. It will be seen that the Weymann principles of construction are employed even for the runners for the luggage container.

As will be Seen from the photographs accompanying this article, .034 Weymann construction for the frame does not interfere in any way with line and design, for curves can be.carried out either by padding or by thin strips of metal panel which do not upset the flexible principle. This is particularly noticeable in the construction of the scuttle and dash. To obtain what is known as a "floating dash" which allows for movement of the scuttle and forward section of the body, a metal panel is often used at the scuttle rail, this being firmly fixed at the forward end but free to move at the rear end. The covering fabric is stretched over this panel and holds it into position, but allows it to slide freely backwards •and forwards under the fabric, thereby permitting distortion to take place without causing any extra load to be taken by the parts concerned.

Finally, the surface of the bodywork should be mentioned: Ordinary fabrics are universally known, so there is no need to describe them here, but it is thought that reference can be made with advantage to some of the special finishes which are now available. Grained fabrics are offered in every colour with every conceivable grain, both fine and coarse, and with shiny or matt finishes., There is, however, a further type of fabric which is now coming into prominence for spraying with cellulose.

Before concluding, some reference should be made to the claims of the sponsors of the Weymannteethod of body construction anent the vulnerability or otherwise of a "flexible" body. when. Involved in an accident. One cannot do better than quote from the Weymann handbook on this matte": "A Weymann body is a strong, resilient structure like a basket, giving a form of protection which a basket can give to its contents, and which one might say, for sake of comparison, a packing-case which tends to shatter cannot offer." Another claim made by the concern is that when a vehicle is involved in an accident there is always a remarkable preservation of glass. Only the glass which is actually struck is broken. There are no tricks in Weymann construction, but as Weymann's Motor Bodies (1925), Ltd., Addlestone, Surrey, has done much experimental work, it is advisable to consult, the company in the" first instance, whether it is to construct the body or not.

Lastly, prices are quite competitive, the bodies of the 26-seater Daimler coach illustrated in detail and the Leyland Tiger saloon shown as a complete vehicle cost well under 1600, despite the fact that luxurious equipment is prodded for the whole of the interior of the vehicle.