A TIPPING GEAR of Australian Origin

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

Some Details of a Gear that Has Proved Efficient in Use.

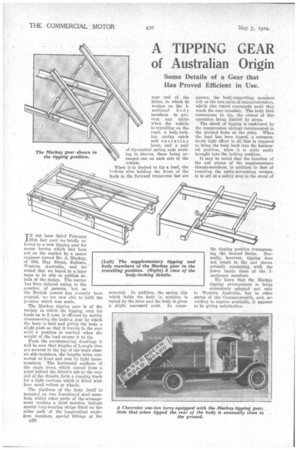

IN our issue dated February 2Stli last year we briefly referred to a new tipping gear for motor lorries which had been put on the market by a motor engineer named Mr. A. Mackay, of 344, Hay Street, Subiaco, _ Western Australia, and we stated that we hoped in a later issue to be able to publish details of the design. The matter has been delayed owing to the question of patents, but as the British patent has recently been granted, we are now able to fulfil the promise which was made.

The Mackay tipping gear is of the variety in which the tipping, even for loads up to 5 tons, is effected by merely disconnecting the locking gear by which the body is held and giving the body a slight push so that it travels to the rear until a position is reached when the weight of the load causes it to tip.

From the accompanying drawings it will be seen that lengths of L-angle iron are secured to the top of the main chassis side-members, the lengths being connected at front and rear by light crossmembers. The horizontal surfaces of the angle irons, which extend from a paint behind the driver's cab to the rear end of the chassis, form a running track for a light carriage which is fitted with four small rollers or wheels.

The platform of the body itself is mounted on two I-sectioned steel members, whilst other parts of the arrangement needing a brief mention include special long-wearing strips fitted on the roller path of the longitudinal angleiron members, special fittings at the rear end of the latter, in which fit wedges on the Isectioned body members to prevent any rattle when the vehicle is travelling on the road, a body-locking spring catch and operating lever, and a pair of tip-control spring rods working in sleeves, these being arranged one on each side of the , vehicle.

When it is desired to tip a load, the lockin.g nins holding the front of the body to the forward transverse bar are removed. In addition, the spring clip which holds the body in position is raised by the lever and the body is given a slight rearward push. In cease quence, the body-supporting members roll on the two pairs of eonnectedrollers, which also travel rearwards until they reach the rear crossbar. The body then commences to tip, the extent of this operation being limited by stops.

The shock of tipping is cushioned by the compression springs incorporated in the pivoted links at the sides. When the load has been tipped, a comparatively light effort is all that is required to bring the body back into the horizontal position, when it is quite easily brought into the locking position.

It may be noted that the function of the end pieces of the supplementary chassis-members, in addition to that of receiving the rattle-preventing wedges, is to act as a safety stop in the event of the tipping position transgress

ing the desired limits. Normally, however, tipping does not result in the end pieces actually contacting with the lower inside faces of the lsectioned members.

We learn that the Mackay tipping arran g,ement is being extensively adopted not only in Western Australia, but in other states of the Commonwealth, and, according to reports available, it appears to be giving satisfaction.