IMPROVING THE COACH CHASSIS.

Page 14

Page 15

Page 16

Page 17

If you've noticed an error in this article please click here to report it so we can fix it.

Efficiency, Silence, Better Appearance, Greater Safety and Comfort, and Lessened Wear and Tear are Features which Could, with Advantage, be Aimed at with Greater Persistency than is Generally"the Case

HOW often is the question asked in connection with motor vehicle design : "Have we reached finality ? " It is a futile question, becatise finality is the hardest thing in the world to attain, and we should all be,naiserable people if perfection were not always. ahead of us • and there was no hope of advancement towards the goal of promise. A better phrasing of the inquiry would be, "Have we attained the greatest possible perfection of design considering the present state of our knowledge ? " . If this question be applied to the motor coach, one has to. admit, in. reply, that many busy brains are at work devising, planning; and contriving to provide that acme of comfort, convenience and safety which the coach-travelling public demands or shows that it expects. But one may well narrow down the question so that it applies to the motor coach chassis, and then it will be found that not every maker has all the virtues and certainly none has

the monopoly thereof. Without looking very far ahead,' or expecting more than a reasonable amount of experimental and research work in connection with the design of chassis intended for passenger work, it is possible to put forward a series of suggestions which should make for the enhanced popularity of the motor coach, increasing the appreciation of the users and acting for the advantages of the owners of the vehicles.

Every suggestion that is herein referred to, with the exception of the drum-type of sprag, is based upon well-tried design, and there is no need for any doubt or fear of failure when considering its adoption. We' have not introduced the subject of more than two axles into this article, because, in the matter of supporting the coach' upon more than four wheels, a certain amount of experimental work must first be undertaken.

We have, therefore confined our attention to the engine, clutch, gearbox, brakes, sprag, universal joints, rear axle, wheels, springs, and radiator.. Appearance goes a long way with the potential passenger, particularly if the coach appears more like a car and less like a lorry.

Dealing first of all with the power unit, we advocate employing a six-cylindered engine as being the most suitable for motor coach purposes. With an

aluminium heart and.a.lighter flywheel than is possible with a four-cylinder type, it should not unduly increase the weight of the chassis. Two, blocks of three cylinders would seem to be the best model for the purpose. A drive for the dynamo should be provided, but a water pump seems to be unnecessary, as sueh good results are obtained with the rmosiphon circulation alone. There would be less to go wrong on the road, as even the best pumps give trouble now and then. Every care should be taken to reduce noise horn valves and timing gears. Pistons, with split skirts and a ring to force the skirt against the cylinder walls, might be used with advantage. Such pistons allow a more liberal supply of oil to all working parts without fear of too much passing the pistons and causing smoke.

Such an engine as described above would be appreciated by the passengers, and its more even torque should lessen wear and tear on all parts. .

A fierce clutch, or one of which no worse can be said than that it is not sweet in action, can make as many bad friends among coach passengers for the coach, to which it is fitted as all the other components of the chassis-put together. The most suitable form of clutch for such a vehicle would seem to be the now favourite single-plate dry clutch. Among its advantages is the fact that it is fairly smooth in action, requires practically no attention, and, working dry, there is no exact degree of lubrication to be maintained.

In the days when a chassis was primarily designed for a lorry, and only occasionally used for a motor coach, little trouble was taken to see that it ran

quietly on all gears. In those days, durability was the main feature aimed at. To-day it.is most essential that silence, in those gearboxes which are destined to he used in vehicles intended for carrying ,passengers, should be studied as 'keenly as in :pleasure car constru tion The design of,silent gearboxes is by no means an easy matter, even in lighter constructions, as many designers of. hikh-class pleasure cars know to their sorrow.

Silence in Gearboxes:

The motor coach gearbox has to transmit more power and has a greater reduction than obtains in the case of atpleasure car ; consequently, great care should be taken in the design ofevery detail that may in any way influence the creation of undue noise In the first place, We may take it that every manufacturerwill see that the teeth of the gears are of

the correct form and evenly cut. Unless this is attended to, it is hopeless to expect anything but noise. Having attained practical perfection in this matter there are several things which maycause undue noise. Among these are the following:— (1) Eccentricity; (2) spring in shafts; (3) bearings wearing loose in the aluminium housings; and (4) wear in the spigot, which throws the shaft out of line. With care in design, most of the troubles can be reduced to.a minimum or even eliminated. •

Eccentricity is largely due to the use of splined shafts, as, in spite of improved methods of manufacture, it is by no means easy to be sure that wheels will revolve truly on a shaft which cannot, without special means, be ground on the portion which gives

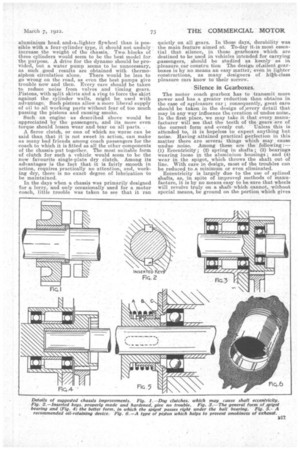

truth to the wheels which revolve with it. It is a question whether it might not be well to revert to the type of sbatf shown in one of the diagrams (Fig. 2), where the mating surfaces can easily besground in ordinary grinding machines to ensure the truth of the wheels. In this type of shaft, inserted keys are used and if properly made and hardened they should give no trolible.

There is another type, shown in Fig. 1, in which the gears are mounted on a shaft without splines or keys, and -rotary motion is imparted to theta by means of dog clutches. This construction is all right so long as the wheel bush remains a good fit on its shaft, but, when wear occurs, the dogs, which are seldom in alignment with the shaft, will influence the wheel and cause eccentricity. It may be asked "why not see that the dog teeth are true," but this is by no means easy, especially in a hardened wheel.

The springing of gearbox shafts is usually due to the shafts being too small in section, which can easily be remedied by enlarging the shafts and, if too heavy, making them hollow. Spring in shaft is also caused by placing the engaging wheels too far from the bearings. There are many gearboxes where all engaging wheels are close up to the bearings, when under load. Another alternative is the use of three bearings to each shaft.

Better Bearing Supports in Gearboxes.

For goods or motor coach chassis, all bearings are Defter ifshoused in a steel liner, the length of which should be considerably greater thansthe width of the ball bearings. The liners should have flanges to prevent movement taking .plece-and the wear which always follows movement, and be fixed to the aluminium case by means of bolts.

Many spigots are far too short and not well supported. It. is not difficult to see that wear in this place will cause the shafts toibe out of position and thus allow gears to stray apart. This will not only cause noise, but, when the spigots ,is rebushed and brought back to its proper position, there is -usually further trouble through the teeth having worn shoulders on their engaging faces, which will take some time to wear right again. Figs. 3 and 4 show two. different constructions of spigots. In Fig. 3 there is an overhangingsportion which is the only support to the spigot, whilst, in Fig. 4, the spigot passes rights under the ball bearing which supports the short shaft. Fig. 4 has been found to give the best, results as regards silent.running.

Efforts have been made to ensure the layshaft remaining still when running in top gear. This does; not seem to be a very necessary refinement, as there is nosparticular difficulty in constructing a .gearbox which is silent on top gear, whilst the stationary layshaft has the effect of making the change tco,a lower gear moreedifficult, owing to the fact that it has to be set going before the other gears can be engaged.

Recent experiences have shown that strains on a gearbox ' can cause it toilse noisy. It is therefore essential. that the well-tried plan of _providing only three,points of suspension to the. gearbox should he ,adhered to. Again, boxes composed of flat sides are not so rigid as those in which the sides are formed of curved surfaces.

Oil-retaining Devices.

The spilling of oil is not only wasteful, but should be avoided on the grounds that it leaves an unsightly mark behind the vehicles wherever they stand to pick up passengers: , This is always objectionable wherever it may happen, but in some surroundings it can even be repulsive. In most modern gearboxes it is necessary to have the oil level in the gearbox fairly high toeensure the spigot of the main shaft getting its proper lubrication.

In eases where difficulty is experienced in preventing leakage of oil, the device shown in Fig. 5 el8 has been found to be most efficient. The flange (B) revolves with the shaft by means of the key (A), and is a good sliding fit on the shaft. It bears against the face (C), which does not revolve. ,A spring is provided to exert the necessary pressure to prevent the escape of oil between the faces. A leakage may take place when the devioe is new, but, after a small amount of wear, no leakage whatever should take place.

Universal Joints.

A great deal of noise in many vehicles comes from the universal joints if they should happen to be worn and slack. Both in front of the gearbox and behind it the universal joint can he responsible for much noise, The tendency to fit only one universal between the engine and gearbox is undoubtedly an effort in the direction of simplicity, but it is doubtful whether it is not simplicity obtained at the expense of efficiency. Recent experiments show that noisY gearboxesean be produced by strains coming on the shafts and thereby forcing them from their right alignment. Two universal joints are, therefore, recommended between engine and gearbox. We now come to the old question as to whether there should be a torque tube or rod, or whether the torque should be borne on the springs. The fprmer plan, if adopted, should include a universal joint situated behind the gearbox, which can be relied upon for silence. For this purpose, the ball or roller bearing type would seem to be the most suitable. In cases where there is no torque tube or rod, the " rag" joint can be relied upon for silence. The ragjoint is composed of a disc of flexible material fixed between two members, each of which has three arms and is known as a spider. This class of joint has proved its suitability for use before the gearbox beyond all doubt, but, in larger vehicles, its use behind the gearbox is still open to doubt. It would seem, however, that it is only a matter of dimensions, as, if of ample size and well designed, there is no reason why it should not stand up to the work.

This joint has so many advantages that everything possible should be done to increase its usefulness. It is absolutely silent, it requires no lubrication, and it will allow of sufficient end-play to relieve the splined shafts of wear and consequent rattle when worn.

The back axle is usually the most difficult part of any chassis design. A light forged axle of the banjo type is suggested as the most suitable on account of its lightness, being an unsprung part. The forging should be of the highest quality of steel and no castings should be used except for the bearings of the worm and as oil retainers. All shoulders and sudden reductions of diameter should be avoided, as these are the primary cause of most axle breakages. Where a shoulder is needed it can be formed by a collar bearing against a slightly conical enlargement. Such a collar will form an efficient abutment for any purpose and bee of equal value to a collar formed integral with the axle. A well designed axle on these lines will save an appreciable amount of weight.

Brakes.

.eIt may be said that if a brake is good enough for a 'lorry, which carries a heavier load, it should be good enough for a motor coach. This is, however, not quite correct, for two reasons. Motor coaches usually operate in picturesque country, which is often of a more-hilly nature than that over which lorries usually travel. An accident with a lorry through inefficient brakes is not so eerious in its results as a . similar accident would i be with a load of human lives. These two reasons call for more attention to

design of brakes when applied to motor coaches.

In our issue of January 24th we illustrated a brake which should be of interest to the designers of motor coaches. This brake was designed primarily with the idea of preventing a rim away backwards, and it should be fitted to every passenger vehicle. With a Blight alteration it could also be used as a third brake for emergencies in either direction, and in this form should be a valuable adjunct to a chassis especially designed for carrying passengers.

It is well understood that the heavier the weight of the vehicle and the load it has to carry, the heavier the springs have to he made. There are, however, two distinct kinds of vibration which have to be dealt with. There is the. slow rise and fall due to an Uneven road surface, and there is the rapid

rattle coming from a road paved with stone setts, as commonly found in the North of England. The larger form of vibration cart be well dealt with by long and well-proportioned springs of the ordinary types. These springs, however, do not seem to deal with the finer form of vibration, which may bel described as being more of a tremor. Consequently, some form of supplementary spring is badly needed for this purpose. Some practical suggestions in connection with this point appeared in our issue of December 27th, which-might prove of value in solving the suspension problem.