For DRIVERS, MECHANICS Sz FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OF TEN SHILLINGS is awarded each week to the sender of the best letter which we publish on this page ; all others are paid for at the rate of a penny a line, with an allowance for photographs. All notes are edited before being published. Mention your employer's name, in confidence, aa evidence of good faith, Address, D., M. and P., "The Commercial Motor," 7-15, Bosebery Avenue, London, E.G. 1.

• Lamps Alight—

Light your lamps at 6.21 in London,. 7.1 in Edinburgh, 6.25 in Newcastle, 6.32 in Liverpool, 6.27 in Birmingham, 6.31 in Bristol, and 7.16 in Dublin.

Improvement to the Design of a Steamwagon Steering Pivot.

The sender of the following communication has been awarded the 10s. prize this week: [1835] " Steamotor " (Strood) writ-es : —"The central steering pivot of a steam wagon is subject., in my opinion, to two failings, it wears rather badly, and is liable to become stiff and difficult to operate. To

my mind, both of these failings are due to a defect in design, inasmuch as the flat bearing surface of the pivot is difficult to lubricate. ,

"The following simple remedy, which I have adopted with success, is applicable to almost any make of vehicle which is fitted with central pivot steering. It is simple and inexpensive,, and affords a marked improvement in respect of both of the two failings on which. I have remarked.

"Simply stated, it. consists -of the provision of a phospher-bronze washer, well grooved for oil, between the steering pinion and the flat surface against ' which it bears.

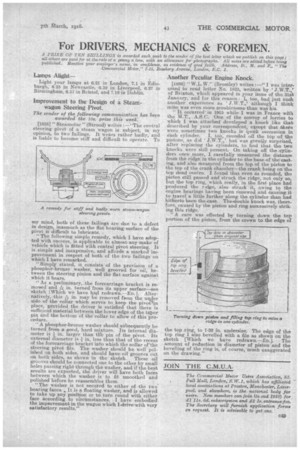

"As a preliminary, the foreearriage bracket is remoaed andu in. turned from its upper surface—see sketch [Which we have hittd redrawn.—En.]. Alter

natively,--this in. may be removed born the under side of the collar which eerves to keep the pivot in place, 'provided the driver is satisfied that there is sufficient material between the lower edge of the taper pin and the bottom of the collar to allow of this procedure.

" A phosphor-bronze washer should subsequently be turned from a good, hard mixture. Its internal diameter is in. larger than the pin of the pivot. Its

external diameter is. ?.y in, less than that of the recess of the forecarriage bracket into which the collar orthe steering pivot fits. The washer should be well p01ished on both sides, and should have oil grooves cut on both sides, as shown in the sketch. These oil grooves should be connected one to the other by small holes passing right through the washer, and if the best Results are expected, the driver will have both faces between which the washer is to fit smoothed and polished before he reassembles them.

"The washer is not secured to either of the two bearing faces.. It is a floating washer, arid is allowed to take up any position or to. turn round with either fate according to circumstances. I have embodied the impaovernent in the wagon which Iadrive-with very satisfactory results."

Another Peculiar Engine Knock.

[1936] " W.L.W." (Bromley) writes :—" I was inter. ested to rekl letter No. 1823, written by J.W.T.,' of Brixton, which appeared in your issue of the 31st January, and for this reason : I, too, had just such

another experience as although I think mine was even more trcnibleSome than was his.

"It occurredin 1915 while I was in France with the M.T., A.S.C. One of the convoy of lorries to which I was, attached developed a knock like that described by your correspondent, except that theta were sometimes two knocks in quick succession in each cylinder. I, too, rounded off the top of the pistons, as did but was greatk surprised, after replacing the' cylinders, to. find that the two knocks were still present. On taking off the .cylinders once more, 1 carefully measured the distance from the ridge' in the cylinder to the baseof the'casting, and also measured from the top of the piston to the top of the crank chamber----the crank being on the top dead centre. 1 found that even as rounded, the piston still passed and struck the ridge, not only so, but the top ring, which really, in the firstplace had produced the r5clge, also struck it, owing to the engine bearings having been renewed and causing it to-travel a little further along the cylinder than had hitherto been the case. Thedouble knock was, therefore, caused by the piston and ring successively striking this ridge.

" A cure was effected by turning down the top portion of the piston, from the crown to the edge of

*Th,

the top ring, to 1-32 in. undersize. The edge of the top ring I also bevelled with a file as shown on the sketch [Which we have redrawn.—En.J. The amount of reduction in diameter of piston and the bevelling of the ring is, of course, much exaggerated on the drawing."