Refuse skips reduce congestion on building sites

Page 87

Page 88

If you've noticed an error in this article please click here to report it so we can fix it.

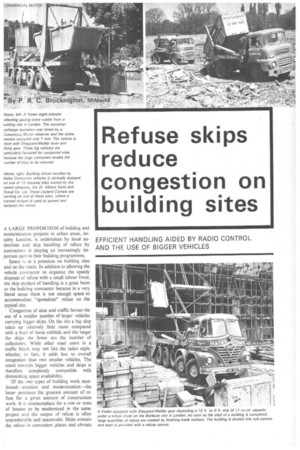

A LARGE PROPORTION of building and modernization projects in urban areas, no tably London, is undertaken by local authorities and skip handling of refuse by contractors is playing an increasingly important part in their building programmes.

Space is at a premium on building sites and on the roads. In addition to allowing the vehicle contractor to organize the speedy disposal of refuse with a small labour force, the skip method of handling is a great boon to the building contractor because in a very literal sense there is not enough space to accommodate "spreadout" refuse on the typical site.

Congestion of sites and traffic favour the use of a smaller number of larger vehicles carrying bigger skips. On the site a big skip takes up relatively little room compared with a load of loose rubbish and the larger the skips the fewer are the number of collections. While other road users in a traffic block may not like the laden eightwheeler, in fact, it adds less to overall congestion than two smaller vehicles. The trend towards bigger vehicles and skips is therefore completely compatible with diminishing space availability.

Of the two types of building work mentioned—erection and modernization—the latter produces the greatest amount of refuse for a given amount of construction work. It is commonplace for a row or rows of houses to be modernized in the same project and the output of refuse is often unpredictable and spasmodic. Skips contain the refuse in convenient places and obviate the serious "nuisance value" of loose refuse to the general public.

It is pertinent that local authorities (and private landlords) are being encouraged by Government grants to modernize rather than re-build older residences, because the houses are substantially constructed and modernization is often the more rewarding. New offices or residences are not often now erected on free spaces in an urban area; building is almost invariably preceded by demolition. The "refuse" of demolition is saleable hardcore and its disposal is therefore in a different category from the disposal of waste refuse.

Sub-centres

When the shell of a building has been erected, large quantities of rubbish are created by the finishing trade workers. For the purpose of refuse disposal, the building is divided into sub-centres for each of which a refuse service is provided. Rubbish is deposited in the chute and discharged to a skip at ground level. On many sites the volume of rubbish produced could not be accommodated in the space available on the ground if it were in loose form.

According to Hales Containers Ltd., Old River Works, White Hart Lane, London, N17, it is impossible to plan ahead by as much as a day in arranging refuse disposal from building and modernization sites in the London area. The amounts of refuse to be collected are variable and unpredictable.

All the company's fleet of more than 60 prime movers (which are used in conjunction with about 850 skips or closed containers on building-refuse and industrialwaste disposal) are equipped with two-way radios. Drivers keep in touch with one of the three depots of the company at Plaistow, Battersea and Tottenham Way where

full-time radio-operators are employed. This has increased vehicle utilization by at least 10 per cent, but of greater importance it has enabled a more efficient service to be organized and promoted customer goodwill.

The latest and biggest vehicles in the fleet comprise five 11 cu.yd. SheppardMeiller vehicles based on Foden eight-wheeled chassis while the remainder include 7+/8 cu.yd., 10-cu.yd. and 12-cu.yd. skip or container vehicles produced by Powell Duffryn or Sheppard Fabrications and based on Albion Cyldesdale 16-ton chassis, Leyland 8-ton Comets, Bedford 15-ton KMRs or on lighter Bedford chassis. Twelve Sheppard Meiller Rolonof 28 cu.yd. compaction containers are based on Bedford chassis and have a compaction ratio of 3/5 to 1. Hales Containers is a wholly owned company of the St. Albans Sand and Gravel Group and refuse is in the main dumped on disposal sites owned by the Group.