ERF FIRE APPLIANCE

Page 79

Page 80

Page 81

Page 82

If you've noticed an error in this article please click here to report it so we can fix it.

and appraisal of ERF/Simon Snorkel escape platform

FIRES cost the nation about £90m a year. While this represents less than £2 a head of population, it's a considerable sum nevertheless and indicates something of the scope there is for companies manufacturing fireprotection equipment. The latest entrant in the fire appliance chassis manufacturing scene—ERF Ltd.—has established a firm foothold in this market in just under four years. It co-operates to build fire engines with HCB-Angus of Southampton, and Snorkel escapes with Simon Engineering (Dudley) Ltd.

COMMERCIAL MOTOR arranged—for this municipal and public utilities issue —to test the ERF /HCB class B water tender. At the same time, through the courtesy of Warwickshire County Fire Brigade, we were able to carry out an appraisal of Warwick's latest acquisition, an 85ft Snorkel escape.

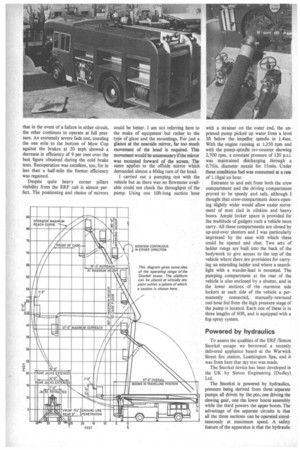

The ERF fire-appliance chassis has been specially designed for the job, having a downward-cranked forward section of the frame to allow for a low-level cabin. The power unit drives through a 15in. clutch to a full-power pto which is incorporated in the clutch bell-housing. A short shaft carries power from the main output shaft of this unit to a five-speed synchromesh gearbox remotely mounted mid-way along the chassis. From there the drive to the rear axle is through a conventional propeller shaft.

The pto can be supplied with either of two ratios, 1 to 2 or 1 to 1.455, and it will transmit a maximum power output of 150 bhp at 4.800 rpm or 100 bhp at 4,000 rpm. Both these figures are continuous ratings.

From its conception ERF made the requirements of after-sales service one of the major guiding lines for the design. Thus, the machine is equipped with standard truck components wherever possible, to provide spares availability from ERF distributor networks throughout the world.

The appliance tested had a wheelbase of lift and was powered by a Perkins 510 cu.in. V8 diesel engine. The Snorkel machine was of 17ft wheelbase, and was powered by the alternative engine, a Rolls-Royce B8I six-cylinder in-line petrol unit.

Putting the fire appliance through its paces in an area bounded .by Sandbach, Holmes Chapel and Scholar Green, Cheshire, my first impression was that it is extremely simple to handle. I was soon able to familiarize myself with the layout of the controls within a quarter-mile I had the feel of the vehicle. This is a most useful characteristic in a unit which might not be driven for long periods by any one man. It must also be recognized that a fire appliance must still be driven smartly under the most adverse conditions and therefore accurate and simple handling is a "must".

No anxiety

I carried out a simulated turn-out to a fire from Brereton Green on A50 over a route through Holmes Chapel to M6, south along M6 to the A534 turn-off and back to A50 and Brereton. This route covered a total distance of 8.6 miles of which one mile comes within the bounds of Holmes Chapel. The circuit was covered at an average speed of 49 mph at a fuel consumption of 8.8 mpg. Throughout this part of the test I found no need for anxiety because of the speed we were travelling. At all times the machine was under absolute control; the extreme flexibility of the Perkins power unit made constant gearchanging unnecessary,

only fourth and fifth gears being used after the start. The maximum speed in fourth gear was 40 mph and, as it was possible to accelerate quite smartly from 27 mph in this ratio, little time was lost through gear changing. To be able to cover a range of speeds from 27 to 62 mph in only two gears has obvious advantages.

Although the machine is not ultimately as fast as some petrol-engined fire appliances tested by this journal, its rapid acceleration —and the ability to hold on to top gear and still accelerate well—makes the driver's job a rewarding but not a tiring one. I did find the noise level on the high side, but as no single journey is likely to be longer than 15 to 20 miles, this is of no great consequence except where it interferes with messages over the radio link with headquarters.

For a hill-climb test I used Mow Cop which has a total length of one mile and an average gradient of 1 in 8. The last few hundred feet of this climb are beyond the capacity of most vehicles but the ERF made short work of it with a gear to spare. Simple starts were accomplished in first and reverse gears with no undue clutch punishment, but upward gear changes were not possible until the gradient slackened. Full results of the hill-climb test can be seen in the results panel.

Braking proved to be very good, but 400-gal of water washing about in the "firstaid" tank carried by the vehicle produced odd results at one time and, although this resulted in the vehicle going slightly off course, I was never concerned from a safety angle. Like other ERF vehicles, the chassis employs spring brakes for parking purposes. A dual-circuit air pressure system feeds independently piped front and rear axles so that in the event of a failure in either circuit, the other continues to operate at full pressure. An extremely severe fade test, coasting the one mile to the bottom of Mow Cop against the brakes at 20 mph showed a decrease in efficiency of 9 per cent over the best figure obtained during the cold brake tests. Recuperation was excellent, too, for in less than a half-mile the former efficiency was regained.

Despite quite heavy corner pillars visibility from the ERF cab is almost perfect. The positioning and choice of mirrors could be better. I am not referring here to the make of equipment but rather to the type of glass and the mountings. For just a glance at the nearside mirror, far too much movement of the head is required. This movement would be unnecessary if the mirror was mounted forward of the screen. The same applies to the offside mirror which demanded almost a 60deg turn of the head.

I carried out a pumping test with the vehicle but as there was no fiowmeter available could not check the throughput of the pump. Using one 10ft-long suction hose with a strainer on the outer end, the unprimed pump picked up water from a level 3ft below the impellor spindle in 1.4sec. With the engine running at 1,350 rpm and with the pump-spindle rev-counter showing 2,700 rpm, a constant pressure of 120 p.s.i. was maintained discharging through a 0.75in. diameter nozzle for 15min. Under these conditions fuel was consumed at a rate of 1.18gal an hour.

Entrance to and exit from both the crew compartment and the driving compartment proved to be speedy and safe, although I thought that crew-compartment doors opening slightly wider would allow easier movement of men clad in oilskins and heavy boots. Ample locker space is provided for the multitude of gadgets such a vehicle must carry. All these compartments are closed by up-and-over shutters and I was particularly impressed by the ease with which these could be opened and shut. Two sets of ladder rungs are built into the back of the bodywork to give access to the top of the vehicle where there are provisions for carrying an extending ladder and where a searchlight with a wander-lead is mounted. The pumping compartment at the rear of the vehicle is also enclosed by a shutter, and in the lower sections of the rearmost side lockers at each side of the vehicle a permanently connected, manually-rewound reel-hose fed from the high pressure stage of the pump is located. Each one of these is in three lengths of 60ft, and is equipped with a fog-spray system.

Powered by hydraulics

To assess the qualities of the ERF /Simon Snorkel escape we borrowed a recently delivered appliance based at the Warwick Street fire station, Leamington Spa, and it was from here that my test was made.

The Snorkel device has been developed in the UK by Simon Engineering (Dudley) Ltd.

The Snorkel is powered by hydraulics, pressure being derived from three separate pumps all driven by the pto, one driving the slewing gear, one the lower boom assembly while the third powers the upper boom. The advantage of the separate circuits is that all the three sections can be operated simultaneously at maximum speed. A safety feature of the apparatus is that the hydraulic circuit powering the main, or lower, boom is isolated until the Stabilizing jacks are extended and locked in position. The mechanical locks cannot be withdrawn until the main boom is fully lowered and parked.

The master control unit is mounted in the cage and this controls slave cylinders built into and powering the main valves. An overriding control allows an operator carried in the pulpit mounted on the turntable to take control of the boom, should the operator in the cage become disabled.

My appraisal of the Warwickshire machine was designed to see just how quickly I could complete a simulated journey to a fire and a "rescue" of two people from a 75fthigh building. A journey of 12.8 miles was run, starting from and finishing at Leamington fire station. The rescue—of two firemen—was made from the training tower.

Two journeys over the circuit and two rescues were carried out. On the first, I drove the vehicle on the road but left the operation of the Snorkel to Station Officer B. L. Fuller. On the second run Officer Fuller drove the vehicle and operated the Snorkel.

My purpose in taking the vehicle on the first trip was to ascertain just how quickly it could be mastered, a good test of handling qualities. Before the test run was started I had not even had the engine running but nevertheless was able to complete the circuit of 12.8 miles—through the centres of Leamington and Warwick, and a stretch Of by-pass—at an average speed of 29.6 mph. Back at the station, jacks were put down and the rescue effected in 4min. 14.8sec.

Being new to the machine I did not expect to make the best possible time and I looked forward to the second run with Officer Fuller at the wheel. My circuit was completed in 26min 11.6sec and the brigade man managed, in slightly worse traffic conditions, to cut 2min lOsecs off my time. However, by placing the vehicle in exactly the right position when we arrived back at the station, the rescue was completed in 2min 44sec. The total time for the first trip from the word "go" to having the rescued persons on the ground was 30min 25.5sec. The second run showed a result of 27min. 33.7sec.

Perfect behaviour

The vehicle behaved perfectly apart from some oversteer. Braking was certain, at no time giving rise to anxiety. I had, ample opportunity to assess its emergency qualities when a small car shot out of a side-turning less than 50ft in front when the ERF was travelling at 37 mph. The Rolls-Royce B81 petrol engine develops a net output of 197 bhp at 3,850 rpm and a net torque of 332 lb.ft. at 2,350 rpm and providing it is kept revving it can move the 15 tons of ERF Simon vehicle very smartly indeed. But as with the water tender interior noise was greater than I had anticipated. During our two runs with the Snorkel the radio link with headquarters was maintained in case the vehicle was needed elsewhere and I became aware of the difficulty in understanding messages being broadcast. As 1 mentioned earlier, this is the only really important reason for reducing the noise level.

When testing turntable ladder fire appliances in the past I have never plucked up courage to ascend the ladder. However, I did not need very much courage to be raised 85ft in the Snorkel and although I must admit to an empty sort of feeling on the ascent, I appreciated that it must be much easier to persuade an elderly lady for instance, on to the platform rather than on to the extremely narrow end of a tui niubI ladder.

I appreciated also the degree of safety offered to a fireman working in the freezing cold some 80ft up, playing water into an inferno below. Officer Fuller impressed on me just how much better it was to be able to stamp one's feet and change one's position when using the monitor jet under those conditions.

The Warwickshire Brigade asked me to make one thing clear and this I gladly do. The Snorkel type of appliance is not a replacement for the turntable ladder; it is complementary to it, and together they offer solutions to almost any task that can be envisaged.