The Latest in Motor Rollers.

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

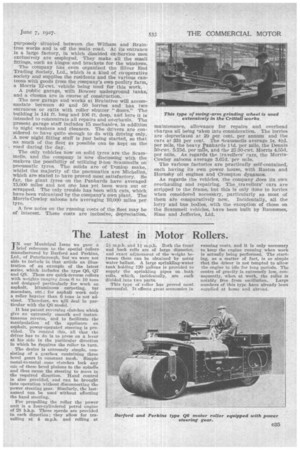

TN our Municipal Issue we gave a brief reference to the special rollers manufactured by Barford and Perkins, Ltd., of Peterberough, but we were not able to include in that article an illustration of an example of the latest series, which includes the type Q6, Q7 and QS. These are quick-reverse rollers with weights ranging from 6 to 10 tons and designed particularly for work on asphalt, bituminous carpeting, tar macadam, etc.; for asphalt work only a roller heavier than 8 tons is not advised. Therefore, we will deal in particular with the Q6 model.

It has patent reversing clutches which give an extremely smooth and instantaneous reverse, and to facilitate the manipulation of the appliance on asphalt, power-operated steering is provided. To control this, all that the driver has to do is to press on a lever at his side in the particular direction in which he requires the rollerto turn.

The device is extremely simple, consisting of a gearbox containing three bevel gears in constant mesh. simple metal-to-metal cone clutches lock any one of these bevel pinions to the spindle and thus cause the steering to move in the required direction. Hand control is also provided, and can be brought into operation without disconnecting the power steering gear. Similarly, the lastnamed can be used without affecting the hand steering.

For propelling the roller the power unit is a four-cylindered petrol engine of 28 b.h.p. Three speeds are provided in each direction ; they allow for travelling at 4 m.p.h. and rolling at

24 m.p.h. and 14 m.p.h. Both the front and back rolls are of large diameter, and exact adjnstment of the weight between them can be obtained by using water ballast. A large sprinkling-water tank holding 120 'gallons is provided to supply the sprinkling pipes on . both rolls, which, incidentally, are each -divided into two parts.

This type of roller has proved most successful. it effects great economies in running costs, and it is only necessary to keep the engine running when work is actually being performed. The starting, as a matter of fact, is so simple that the driver is not tempted to allow the engine to idle for long periods. The centre of gravity is extremely low, consequently, when at work, the roller is notably free from oscillation. Large numbers of this type have already been supplied at home and abroad.