LONDON'S SIX-WHEELED COVERED-TOP BUS.

Page 48

Page 49

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

The Passenger-carrying Capacity of London's Largest Bus Now Double what it was Eight Years Ago. The Latest Application of the Six-wheel Principle so Strongly Advocated by this Journal.

A S was briefly announced in last -week's issue, the „CI-London General Omnibus Co., Ltd., has now disclosed its intention (of which we have, of course, known for some Little time) to develop the use of the six-wheeled omnibus for' London, and we have been privileged to examine the fi.7st vehicle that has been constructed and to see chassis in course of manufacture.

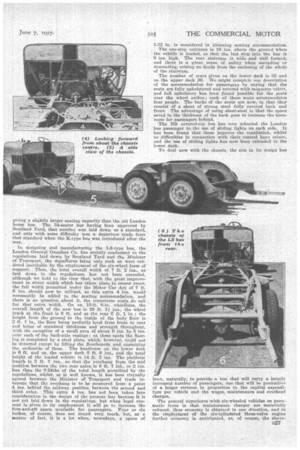

The illustrations which accompany this description will give a very close idea of the appearance of the bus, with the one exception that the three-quarter front view apparently somewhat elongates the engine bonnet and reduces its width. Generally, the vehicle is extremely shapely, the lines being very good indeed, and, with its six wheels, each equipped with large pneumatic tyres (36-in. by 8-in.), does not seem to be "over-wheeled." The enclosing of the rear staircase might tend to make the rear of the bus cumbersome, but the scheme of decoration, under which the window band is painted white, completely saves this and avoids any undue appearance of weight in the overhang.

The six-wheeled bus has been submitthd to the Public Carriage Department of Scotland Yard in the drawing form and, again, since its completion. When the drawings were submitted they were considered and finally approved for experimental construction, and with commendable expedition Scotland Yard's inspection—thorough as it was —was completed within a few days, and final approval for the vehicle to be placed on service was granted on Thursday afternoon last.

A decision as to the construction of further vehicles of the type will no doubt be come to very shortly, as experience with the K, S, and NS-types of bus, with their larger seating capacity, has definitely shown that the large bus (as distinct from the 34-seater B-type, which was the standard before and during the war) introduced no difficulties in traffic control; in fact, the position is rather the

opposite, in that it is better to carry, say, 68 passengers in one vehicle than in two vehicles, tending, as it must do, to the reduction of traffic congestion.

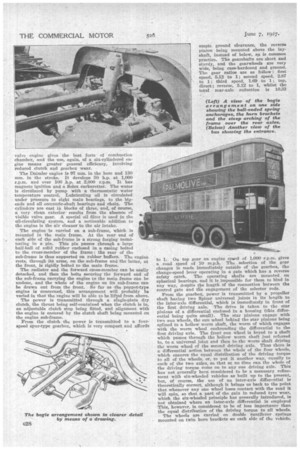

The new type is to be known as the LS (meaning "London Six"). No. 1 has been constructed on an 18-ft. 6-in, wheelbase to seat 68 passengers and is of the type which has been decided upon for London. It is equipped with a 60-120 h.p. six cylindered Daimler sleeve-valve engine, and, of course, has a covered upper deck equipped with upholstered seats.

LS2 and LS3, now under construction and which we have seen in chassis form, are being built on a 17-ft. 6-in, wheelbase, and will be engined with an 85 h.p. six-cylindered poppet-valve A.D.C. power unit. The wheelbase, although shorter, and, therefore, giving a smaller turning radius, will not involve any reduction in seating capacity, as both types—that for London and that for provincial cities—will each seat 68 passengers. This, as -will be seen, is exactly double the capacity of all the early types of motorbus used in London up to and ,including the B-type. The first motorbus that came over from Germany had 34 seats, giving a slightly larger seating capacity than the old London horse bus. The 34-seater bus having been approved by Scotland Yard, that number was laid down as a standard, and only with some difficulty was a departure made from that standard when the K-type bus was introduced after the war.

In designing and manufacturing the LS-type bus, the London General Omnibus Co. has strictly conforined to the regulations laid down by Scotland Yard and the Minister of Transport, the deparlures being only such as were rendered inevitable by the employment of the six-wheel form of support. Thus, the total overall width of 7 ft. 2 ins., as laid down in the regulations, has not been exceeded, although we held to the view that, with the great improvement in street width which has taken place in recent years, the full width permitted under the Motor Car Act of 7 ft8 ins. should now be utilized, as this extra 4 ins. would necessarily be added to the seating accommodation, and there is no question about it, the transverse seats do call for that extra width. On an 18-ft. 6-in. wheelbase, the overall length of the new bus is 29 ft. II. ins., the wheel track at the front is 6 ft. and at the rear 6 ft. 1 in.; the height from the ground to the inside of the body floor is 2 ft. 1 in., the floor being perfectly level from front to rear and being of standard thickness and strength throughout, with the exception of a small area of about 6 ins. by 5 ins. over each of the back-axle casings ; at these spots the flooring is completed by a steel plate, which, however, could not be detected except by lifting the floorboards and examining the underside of them. The headroom on the lower deck is 6 ft. and on the upper deck 5 ft. 9 ins., and the total height of the loaded vehicle is 14 ft. 3 ins. The platform length is 3 ft. 7 ins., so that the overhang from the mid position between the two rear axles.' is 8 ft. 7 ins., or 2 ins. less than the 7-24ths of the total length permitted by the regulations, whilst, as is well known, it has been virtually agreed between the Minister of Transport and trade interests that the overhang is to be measured from a point 4 ins. behind the midway position between the second and third axles. This extra 4 ins, has not been taken into consideration in the design of the present bus because it is not yet laid down in the regulations, but when legal consent is given to its employment it will go to increase the fore-and-aft space available for passengers. Four or six inches, of course, does not sound very much, but, as a matter of fact, it is a lot when, nowadays, a space of

1-32 in. is considered in planning seating accommodation.

The one-step entrance is 16 iris above the ground when the vehicle is loaded, so that the last step into the bus is 9 ins. high. The rear staircase is wide and well formed, and there is a great sense of safety when ascending or descending, arising no doubt from the enclosing of the whole of the staircase.

The number of seats given on the lower deck is 32 and on the upper deck 36. We might complete our description of the accommodation for passengers by saying that the seats are fully upholstered and covered with moquette velvet, and full upholstery has been found possible for the seats over the wheel arches ; each of these scats accommodates four people, The backs of the seats are new, in that they consist of a sheet of strong steel fully covered back and front. The advantage of using sheet-steel is that the space saved in the thickness of the back •goes to increase the kneeroom for passengers behind.

The NS covered-top bus has now schooled the London bus passenger to the use of sliding lights on each side. It has been found that these improve the ventilation, whilst no difficulties in connection with their control have arisen, and the use of sliding lights has now been extended to the lower deck.

To deal now with the chassis, the aim in its design has

been, naturally, to provide a bus that will carry a largely increased number of passengers, one that will be productive of a larger revenue in proportion to the capital expenditure per vehicle and the wages, maintenance and overhead

charges. •

The general experience with six-wheeled vehicles on pneumatic tyres is that maintenance charges are materially reduced, thus economy is obtained in one direction, and in the employment of the six-cylindered three-valve engine further economy is anticipated, as, of course, the sleeve

valve engine gives the best form of combustion chamber, and the use, again, of a six-cylindered engine means greater general efficiency, involving reduced clutch and gearbox wear.

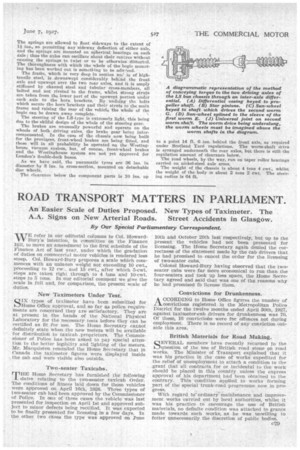

The Daimler engine is 97 mm. in the bore and 130 mm. in the stroke. It develops 50 h.p. at 1,000 r.p.m. and over 100 h.p. at 2,000 r.p.m. It has magneto ignition and a Solex carburetter. The water is circulated by pump with a thermostatic water temperature control. Lubricating oil is circulated under pressure to eight main bearings, to the bigends and all eccentric-shaft bearings and chain. The cylinders are cast in blocks of three, and, of course, a very clean exterior results from the absence of visible valve gear. A special oil filter is used in the oil-circulating system, and a noticeable addition to the engine is the air cleaner to the air intake.

The engine is carried on a sub-frame, which is mounted in the main frame. At the rear end of each side of the sub-frame is a strong forging terminating in a pin. This pin passes through a large half-ball of solid rubber enclosed in a casing bolted to the cross-member of the frame ; the rear of the sub-frame is thus supported on rubber buffers. The engine rests, through its arras, on the sub-frame and the latter, at the front, is rigidly bolted to the main frame.

The radiator and the forward cross-member can be easily detached, and then the bolts securing the forward end of the sub-frame carrying the engine to the main frame can be undone, and the whole of the engine on its sub-frame can be drawn out from the front. So far as the poppet-type engine is concerned, this arrangement will probably be varied in that the engine will be able to be lifted from above.

The power is transmitted through a single-plate dry clutch, the thrust being self-contained when the clutch is in, an adjustable clutch stop being fitted, and alignment with the engine is ensured by the clutch shaft being mounted on the engine sub-frame.

From the clutch the power is transmitted to a fourspeed spur-type gearbox, which is very compact and affords

ample ground clearance, the reverse pinion being mounted above the layshaft, instead of below, as is common practice. The gearshafts are short and sturdy, and the gearwheels are very wide, being case-hardened and ground. The gear ratios are as follow: first speed, 5.12 to 1; second speed, 2.87 to 1; third speed, L69 to 1; top, direct; reverse, 5.12 to 1, whilst the total rear-axle reduction is 10.33

to 1. On top gear an engine speed of 1,000 r.p.m. gives a road speed of 10 m.p.h. The selection of the gear changes is made immediately outside of the gearbox, the change-speed lever operating in a gate which has a reverse safety catch. The operating shafts are mounted on spherical bearings, and it is impossible for them to bind in any way, despite the length of the connection between the control gate and the engagement of the selector rods. From the gearbox, power is transmitted by a propeller shaft having two Spicer universal joints in its length to the inter-axle differential, which is immediately in front of the first driving axle. The drive is taken to the star pinions of a differential enclosed in a housing (this differential being quite small). The star pinions engage with two sun wheels, the sun wheel behind the star pinions being splined to a hollow worm shaft, the worm of which engages with the worm wheel enshrouding the differential to the first driving axle. The front sun wheel is keyed to a shaft which passes through the hollow worm shaft just referred to, to a universal joint and then to the worm shaft driving the worm wheel of the second driving axle. Thus there is a differential action between the whole of the four wheels, which ensures the equal distribution of the driving torque to all of the wheels, or, to put it another way, equally to each of the two axles, so that at no time can the whole of the driving torque come on to any one driving axle. This has not generally been considered to be a necessary refinement with six-wheeled vehicles as built up to the present, but, of course, the use of an inter-axle differential is theoretically correct, although it brings us back to the point that whenever any one wheel loses contact with the road it will spin, so that a part of the gain in reduced tyre wear, which the six-wheeled principle has generally introduced, is not obtained where an inter-axle differential is employed This, however, is considered to be of less importance than the equal distribution of the driving torque to all wheels.

The wheels are carried on double cantilever springs mounted on twin horn brackets en each side of the vehicle. The springs are allowed to float sideways to the extent of ins., so permitting any sideway deflection of either axle. and the springs are mounted on spherical bearings on each axle; thus the axles can oscillate about their centres without causing the springs to twist or to be otherwise distorted. The thoroughness with which the whole of the bogie mounting has been worked out is something to be adreired.

The frathe, which is very deep in section am is of hightensile steel, is downswept considerably behind the front axle and .upswept over the two rear axles, and it is amply stiffened by channel steel and tubular cross-members, all bolted and not riveted to the frame, whilst strong struts are taken from the lower part of the upswept portion under each axle to the horn brackets. By undoing the bolts which secure the horn brackets and their struts to the main frame and raising the rear of the vehicle the whole of the bogie can be drawn away complete. The steering of the LS-type is extremely light, this being due to the skilful design of the whole of the steering gear. The brakes are unusually powerful and operate on the wheels of both driving axles, the brake gear 'Wine. intercompensated. In the case of the chassis now being built for the provinces, front-wheel brakes are being fitted, and these will in all probability be operated on the Westinghouse vacuum system, but, of course, front-wheel brakes and the Westinghouse system are not yet approved for London's double-deck buses.

As we have said, the pneumatic tyres are 36 ins. in diameter by 8 ins, in cross-section, mounted on detachable disc wheels.

The clearance below the component parts is 10 ins, up

to a point 14 ft. 6 ins, behind the front axle, as required under Scotland Yard regulations. The worm-shaft drive is arranged underneath the rear axles, but there is still the regillation amount of clearance below.

The road wheels, by the way, run on taper roller bearings carried on nickel-steel axle arms.

The weight of the chassis is about 4 tons 4 cwt., whilst the weight of the body is about 2 tons 2 cwt. The steering radius is 64 ft.