The Army displays its versatility

Page 57

Page 58

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

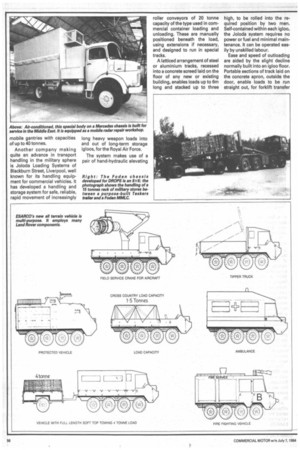

Working in close conjunction with Land Rover for example, CSC (Specialised Vehicles) Ltd, of Milton Keynes has developed a range of demountable bodies for Land Rover all-terrain vehicles. These made their debut at BAEE. CSC points out that the miniaturisation of a wide variety of equipment, particularly in the field of electronic engineering, has made it possible for much smaller enclosures to be used for housing equipment for mobile deployment than the standard containers and shelters previously built for use in conjunction with flatbed trucks.

As a result a wide variety of military applications, both within the British Army and land based forces overseas, is envisaged for the demountable bodies CSC is producing; from communications and weaponry control through to field maintenance and emergency relief. Here is a fuller list: 1. Radio relay; 2. Communications vehicle; 3. Command post; 4. Surveillance/di re ct i o n finding; 5. Electronic support and counter measures; 6. Artillery control; 7. NBC monitoring; 8. Electronic workshop; 9. Mechanical workshop; 10. Internal security roles; 11. Emergency relief control and co-ordination; 12. Ambulance; and 13. Office/check point control.

The demountable bodies developed by CSC are suitable for use in conjunction with Land Rover 110in and 127in wheelbase models. They can also be fitted on three-axle versions of the Land Rover.

Dimensions of CSC's new demountable Land Rover body are length: internal 1,960 mm; external 2,080mm. Width: internal 1,62 Omm; external 1,720mm. Height: internal 1,710mm; external 1,950 (including solar canopy). CSC says that the flexibility of the jointly developed system will provide

Below: As the result of a joint project with Land Rover, CSC has developed this demountable body on the Land Rover 110.

Land Rover fleet owners with a multi-body potential while at the same time retaining the cargo carrying and all-terrain capability characteristics of the Land Rover itself.

Two basic body units are available, one fitted within the standard Land Rover 110 high capacity pick-up body; and the second a body which is interchangeable with the standard pick-up unit and secured by a total of nine bolts.

The bodies are equipped with lifting rings at the top four corners to permit demounting by crane. There are jacking points available as an alternative method of demounting the bodies.

Another BAEE exhibit from CSC was a mobile radar repair workshop destined for a customer in the Middle East. It is part of an on-going contract for the supply of a fleet of field maintenance and repair workshops. The unit is of all aluminium construction and is mounted directly on to a Mercedes 4 x 4 bonneted 911 chassis. Equipped with air conditioning, the workshop is fitted with basic furniture, electrical circuits and a G & M Power Plant 15 KVA generator.

To handle the increasing number of containers in military use Modular Distribution Systems Ltd of Westwood, Peterborough, has developed a range of mechanical demount systems which can handle a wide variety of containers.

MDS emphasises that its transfer systems are all weight tested and ACTC certified. MDS has an 05-29 Defence Standard Approval.

Two light standard transfer systems are offered. One of these is the MDS88, a lift/lower systems in which telescopic support legs are inserted in each of the four corner posts on the body and then lowered manually using a ratchet control with lifting capacities from 21/2 to 8 tonnes. The second is the MDS205 a power operated system but one man controlled with lifting capacities from 11/2 to Iz tonnes. Then there are the MDS88/HH and MDS16 with lifting capacities of 20 to 30 tonnes and 20 to 40 tonnes respectively.

The company also makes road/rail container transfer systems, giant lift platforms and mobile gantries with capacities of up to 40 tonnes.

Another company making quite an advance in transport handling in the military sphere is Joloda Loading Systems of Blackburn Street, Liverpool, well known for its handling equipment for commercial vehicles. It has developed a handling and storage system for safe, reliable, rapid movement of increasingly long heavy weapon loads into and out of long-term storage igloos, for the Royal Air Force.

The system makes use of a pair of hand-hydraulic elevating roller conveyors of 20 tonne capacity of the type used in commercial container loading and unloading. These are manually positioned beneath the load, using extensions if necessary, and designed to run in special tracks.

A latticed arrangement of steel or aluminium tracks, recessed into a concrete screed laid on the floor of any new or existing building, enables loads up to 6m long and stacked up to three high, to be rolled into the required position by two men. Self-contained within each igloo, the Joloda system requires no power or fuel and minimal maintenance. It can be operated easily by unskilled labour.

Ease and speed of outloading are aided by the slight decline normally built into an igloo floor. Portable sections of track laid on the concrete apron, outside the door, enable loads to be run straight out, for forklift transfer to airfield vehicles. There is no equipment outside the building when the system is not in use, Joloda points out.

The Scammell vehicles for DROPS were described in detail in the June 16 issue of CM. Although the two main suppliers of the load racks for DROPS namely Multilift and MarshaIls, showed their equipment at the BAEE, a notable absentee was Foden, the alternative chassis maker to Scammell. The Foden vehicles for DROPS were, however, demonstrated in the week leading up to BAEE and both their designs are 8 x 6s, one a Medium Mobility Load Carrier (MMLC) and the other an Improved Medium Mobility Load Carrier (IMMLC). Both are powered by Rolls Royce 340 Eagle Diesel engines matched with Allison fully automatic transmissions. All axles are Kirkstalls, the second axle being the non driven unit.

The Foden IMMLC differs from the MMLC in that it is equipped with a crew cab, is wider at 9ft 61n (compared with 8ft 2.5in) and has larger tyres to improve its cross-country operating capability.

An eight wheeler of a rather different kind was also exhibited called the ESARCO, made by a relatively new company ESARCO Ltd, of Ludgershall, Wiltshire.

Built for a payload of 1.5 tonnes, it is basically designed as a military vehicle for operation over soft boggy surfaces. Accordingly it is equipped with fat, low profile 31 x 15.50-15STG tyres. It can operate with four of its wheels driven, or all eight of them driven. All its mechanical parts are Land-Rover One-Ten components and the chassis itself consists of two mild steel fabricated box section members with four box section crossmembers carrying brackets for the axle suspension, engine and body parts.

Powered by the Land Rover 3.5 litre V8 petrol engine producing 114bhp, it has either the Land-Rover four or five-speed gearbox plus two transfer boxes, one for numbers one and three axles and one for numbers two and four axles. There is differential locking on all wheels.

Built to travel on and off the road, it has a 4 tonnes towing capability.

As with the ESARCO, other specialist manufacturers rely heavily on Land-Rover components to produce their products. Hotspur Armoured Products Ltd of Neath is notable in this connection and its latest products were on show at BAEE.

Hotspur is a main producer of 6 x 4 and 6 x 6 Land Rover-based designs, both armoured and soft-skinned. Its range includes truck-bodied units, ambulances and fire appliances.

A company that does not rely on Land-Rover components is Gomba-Stonefield, the manufacturer that originated in Cumnock, Ayrshire, although still in residence in Scotland, Gomba seems to have located most of its vehicle production facilities at its Trans-Ax factory at Strood near Rochester in Kent.

After relying heavily for some years on the Chrysler V8 petrol engine and Chrysler automatic transmission the company is to offer its first diesel — a Deutz 160 bhp V8. This is the engine developed in Canada for the US Army's HMMWV programme. The engine is to be made in Germany and Gomba-Stonefield is to be one of the first manufacturers to fit it.

In terms of bigger vehicles the first appearance of the Bedford 6 x 6 drew some attention.

Developed from the current Bedford military 4 x 4, it fits the TM cab and is powered by a Bedford 8.2 litre turbocharged engine developing 206 bhp at 2,500 rpm. This is matched with a ZF S6-80 six-speed gearbox and Kirkstall two-speed transfer box. Axles are all GKN Kirkstalls with hub reduction. Designed to operate at a gross weight of 24,390 kg it offers a payload of 14,000 kg. There was a Bedford look to the Boughton 6 x 6 on display, not surprisingly as this mediummobility load carrier currently under trial with the US Army uses what is basically the Bedford cab. It is built for gross weight operation at 26,600 kg and a payload of 14,000 kg. A Rolls-Royce 450 bhp CVS engine provides the power and an Allison HT 750 DRD automatic the transmission.

Bedfords remain the "bread and butter" vehicle of the British Army and there were a number at BAEE being put to all kinds of uses; notably perhaps by Fairey Engineering where they were used for the base of a display of bridge sections.

Finally there were the tank transporters, notably Crane Fruehauf's Class 90 tank transporter. This is just going into service with the British Army. It has a capacity of 62 tonnes and is designed to carry the Chieftain and Challenger main battle tanks.

The basic construction consists of fabricated steel "I" beam main chassis members with welded "I" section and channel cross members. Track areas are fully decked with load bearing plates with lighter plating or grating elsewhere. The main bed has a flat length of 5.67m with a width of 3.46m. Two fabricated loading ramps are fitted, designed for one man operation. Safety devices are fitted to ensure complete security in the stowed position. Twin supports are provided at the front of the trailer and are mechanical/hydraulic in operation. They are capable of supporting the trailer and raising the trailer while fully loaded.

The trailer suspension is of an unsprung, walking beam, design with each end of the fabricated beam supporting a short oscillating axle pivoted on a grease packed nylon bush. There are four centrally pivoted transverse axles, in two lines, carrying offset disc wheels with tubeless tyres. Brakes are two line air with 419mm x 219mm 'S' Cam operated linings on all wheels. Parking is via spring chambers on the trailing bogie axle which also acts as a breakaway emergency system.

Then there was a new design of battle transporter (the D400RT) from DJB Engineering of Peterlee, Co. Durham, developed from the company's D400 off-highway articulated dump truck. It is a six-wheeled drive design featuring two independent front and rear chassis frames.