GARAGE PLANT AND EQUIPMENT.

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

WEIE1Nt a vehicle is under repair it is often advantageous to be able to raise two wheels, to increase the ground clearance temporarily, so that

a fitter can work underneath, and inclined supports are frequently employed for the purpose. " G.A.L.," of Washington, D.C., advocates a simple type of device which retains a wheel in an elevated position without the aid of scotches or other objects. For this and the following suggestion this week's prize of .15. is awarded.

, The automatic support takes the form of a box without a lid, having one side slightly less in height than the other three and bevelled outwards, in order to accommodate the sloping plank. The material of which the box is oon,structed must be stout, as it has to bear a con siderable portion of the weight of the vehicle. The plank is bevelled at the end which rests upon the ground, and hinged to the box portion. That end of the plank which is within the limits of the box must be slightly shorter than the internal distance between the two ends of the box, in order to provide clearance for movement. As will be seen, when the vehicle is driven up the incline, the wheel reaches a point which is beyond the hinge, and the weight automatically tips up the plank, holding the wheel between the plank and the end of the box.

Care should be taken to see that the free end of the Plank is not too long, otherwise, it may rise and strike the underside of the vehicle. A stop is also advisable to prevent excessive movement of the plank. A pair of these devices is preferable to tire use of one only, as a serious stress may be thrown upon the chassis by lifting one wheel alone.

" G.A.L." also suggests a device for holding bolt-fixed disc wheels when tyre fitting is in progress. A stout wooden barrel is necessary, filled with a good quantity of earth or sand in order to keep it steady when force is applied to the wheel in position. Across the open end of the barrel are fixed wooden slats which are nailed in position ; across these slats are placed others, retained in position by coach bolts, the threaded ends of which project upwards. Upon these bolts are fixed the wheels.

USERS of blow-lamps" will appre ciate a series of "Dents " which are submitted by ".T.R.N.." of Stainford.

Don't fill the container without a funnel to filter the paraffin.

Don't use paraffin to heat the vaporizer ; methylated "spirit saves pricking out the jet.

Don't use a pricker without first removing the bur on it, or the let size will be increased and flaming will result.

Don't take the pump out of the container, if the spindle rises flue to a leaky valve. Withdraw the spindle and pour a little paraffin down the valve: another stroke of the plunger will clear the pump.

Don't pump continnonsly, if the flame be dim, without pricking out the jet. or the container may burst.

Don't replace the jet without smearing a little blacklead on the threads.

Don't despair if the pump will not work, but remove the cap and tighten up the nut holding the ileather washer on. to the bucket.

Don't leave methylated spirit lying about, as it evaporates rapidlyand is apt to disappear in other ways.

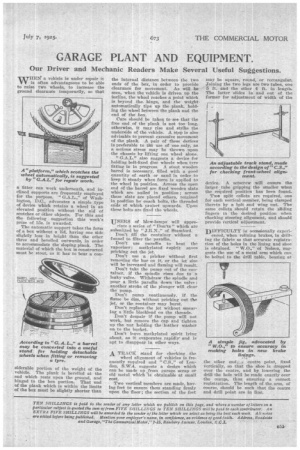

A TRACK stand for checking the

wheel alignment of vehicles is frequently required and "C..," of London, S.W.4, suggests a design which can be made up from garage scrap or old metal which is obtainable at small cost Two vertical members are made, having feet to ensure them standing firmly upon the floor ; the section of the feet may be square, round, or rectangular. Joining the two legs are two tubes,. one 5 ft. and the other 4 ft. in length. The latter slides in and out of the former for adjustment of width of the device. A setscrew will ensure the larger tube gripping the smaller when the required position has been found.

Two split collets are required, one for each vertical member, being clamped thereto by a bolt and wing nut. The same collets should retain the sliding fingers in the desired position when checking steering alignment, and should provide vertical adjustment.

DIFFICULTY is occasionally experi enced, when relining brakes, in drilling the fabric so that accurate registration of the holes in the lining and shoe is obtained. " W.O.," of Nelson, Suggests the use of a metal arm which can be bolted to the drill table, bearing at

the other endi centre point, fixed vertically, so that the shoe is dropped over the centre, and by lowering the drill the hole will he made exactly over the centre, thus ensuring a correct registration. The length of the arm, of course, should be such that the centre and drill point are in line.