Thanks to the Government's decision to keep VED rates for

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

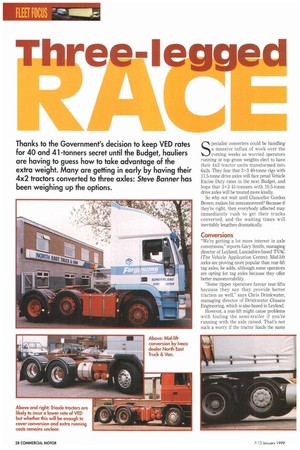

40 and 41-tonners secret until the Budget, hauliers are having to guess how to take advantage of the extra weight. Many are getting in early by having their 4x2 tractors converted to three axles: Steve Banner has been weighing up the options.

Specialist converters could be handling a massive influx of work over the coming weeks as worried operators running at top gross weights elect to have their 4x2 tractor units transformed into 6x2s. They fear that 2+3 40-tonne rigs with 11.5-tonne drive axles will face penal Vehicle Excise Duty rates in the next Budget, and hope that 3+3 41-tonners with 10.5-tonne drive axles will be treated more kindly.

So why not wait until Chancellor Gordon Brown, makes his announcement? Because if they're right, then everybody affected may immediately rush to get their trucks converted, and the waiting times will inevitably lengthen dramatically.

Conversions

"We're getting a lot more interest in axle conversions," reports Gary Smith, managing director of Leyland, Lancashire-based TVAC (The Vehicle Application Centre). Mid-lift axles are proving more popular than rear-lift tag axles, he adds, although some operators are opting for tag axles because they offer better manoeuvrability.

Some tipper operators favour rear-lifts because they say they provide better traction as well," says Chris Drinkwater, managing director of Drinkwater Chassis Engineering, which is also based in Leyland.

However, a rear-lift might cause problems with fouling the semi-trailer if you're running with the axle raised. That's not such a worry if the tractor hauls the same trailer every day because the conversion should have been engineered with this in mind; but it can be a headache if you're on traction-only work and pulling a variety of trailers, A rear-lift can also land you with overall length problems, and doesn't do much for the appearance of your unit, comments David Brain, operations director at Leighton Buzzard, Bucks-based converter Chassis Developments. "Bluntly, they don't look nice," he remarks.

On the other hand, if the conversion is not properly thought-out, a mid-lift can wallop the underside of your tractor's chassis. It might also be impossible to fit if your tractor has a low-height chassis with insufficient clearance. "In those circumstances it might be worth thinking about having a full-width refuse collection vehicle type mid-lift installed with 19.5in wheels," Drinkwater suggests. It will be about the same price as a standard mid-lift, but the wheels and tyres will be cheaper."

Running with a mid-lift down when unladen may reduce traction because less load will be imposed on the drive axle, warns Brain. Also, laden or unladen, the tyres might suffer from scrub.

Customer

Whichever route the customer chooses, prices range from £5,000 to as much as £9,000, not counting the cost of a set of wheels and tyres—and TVAC is among those happy to offer a two year/unlimitedmileage warranty.

Whether you're opting for mid-lift or rearlift, the weight penalty will range from 750kg to approaching 1,000kg. The extra weight is bound to affect fuel consumption and this work takes time. Smith warns: "You're looking at a minimum 40 hours, and it can be as much as 75 hours, so the guy can expect to lose the use of his truck for at least five days."

To ensure the unit spends as little time at TVAC as possible, Smith encourages hauliers to remove the fifth wheel themselves.

What about opting for a twin-steer conversion, or turning your 4x2 into a 6x4? That's really too complicated and too expensive to be a practical proposition for the average haulier.

Fitting a mid-lift can be a problem for hauliers on Continental work who want to install the largest possible fuel tanks so that they can fill 1.11) with as much cheap European diesel as possible. The additional wheels eat into tank space—a disadvantage a rearlift doesn't share—so some repackaging of the chassis may be required to create more room for tankage. This might entail fitting a vertical exhaust and moving the batteries, or installing creatively shaped alloy tanks that can make maximum use of every nook and cranny.

Even so, tank capacity can still be halved, Brain warns, so operators will have to balance the higher VED a 4x2 may pay against its ability to take greater advantage of the availability of low-cost fuel. And remember, even if the chassis hasn't been radically rearranged, an extra axle constitutes a notifiable alteration, so a VTGIO form will have to be completed.

Having gone to all the trouble of having a mid-lift installed and having his rig plated at 41 tonnes, an international operator travelling to or through France risks being clobbered by the French 40tonne weight restriction on sixaxle artics; a limit that, on past showing, the French are likely to enforce,

It's usually impossible to fit a mid-lift to a chassis with a wheelbase of less than 3.8m without having the wheelbase altered. "Even if it's 3.7m, it'll need lengthening," says Drinkwater.

Engineering

Iveco Ford operators looking for a mid-lift are likely to be pointed in the direction of dealer North East Truck & Van, which has an extensive engineering operation. "We don't like rear-lifts because of the weight distribution problems, and because of the danger of damage being done to the trailer," says an Iveco Ford spokesman.

Mercedes-Benz fits mid-lifts at its Wentworth Park, I3arnsley site, and might have one available as a line-fit option by the middle of next year.

Leyland Daf doesn't approve particular conversions, but may issue a letter of no objection to at least one independent mid-lift conversion during 1999. It doesn't favour aftermarket rear-lifts.

Cleverly, ERF has been running an advertising campaign telling hauliers that if they buy an ERF 4x2 now, and find the VED rates punitive come March, then they can have a mid-lift installed at no more than they would have paid had they bought a 6x2 in the first place. "Our standard wheelbase is 3.8m, and we pre-drill the chassis to make it easier to fit a lift axle," says marketing manager Matt Thompson. Dealers are supplied with the necessary kit to carry out the conversion work.

Even though they may want to get their trucks converted as soon as possible, operators should be wary about rushing into adding axles until they have the March Budget figures in front of them, says Leyland Daf marketing director Tony Pain. They should also consider all the extra running expenses generated by an additional axle—and Pain warns that some of these aren't immediately obvious.

"You've got higher maintenance costs, more tyre wear, although clearly a lift axle isn't down all the time, and more tyres to replace," he points out. One more axle is one more axle that can become misaligned, he adds, increasing fuel consumption. "Start taking some of these things into consideration, plus the cost of having the axle fitted, and you start to realise that a conversion may not be worth while if the difference in VED is only, say, £2,000 a year," he concludes. "But it does make more sense if the difference is £5,000."