on trial: FORD NAM 4x 4

Page 33

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

1340N-GROSS

TIPPER by Trevor Longcroft

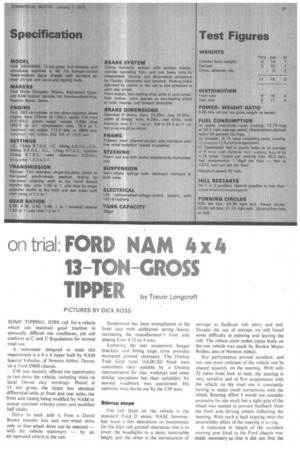

PICTURES BY DICK ROSS SOME TIPPING JOBS call for a vehicle which can maintain good traction in unusually difficult site conditions, yet still conform to C and U Regulations for normal road use.

A newcomer designed to meet this requirement is a 4 x 4 tipper built by NAM Special Vehicles, of Newton Abbot, Devon, on a Ford D800 chassis.

CM was recently offered the opportunity to test-drive the vehicle, including trials on local Devon clay workings. Plated at 13 ton gross, the tipper has identical differential units at front and rear axles, the front axle casing being modified by NAM to accept constant velocity joints and modified halfshafts.

Drive to each axle is from a David Brown transfer box and rear-wheel drive only or four-wheel drive can be selected — with the vehicle stationary — by an air-operated switch in the cab. Suspension has been strengthened at the front axle with additional spring leaves, increasing the manufacturer's front axle plating from 4.75 to 5 tons.

Lowering the rear suspension hanger brackets and fitting large tyres provides increased ground clearance. The Dunlop Trak Grip tyres (14.00-20) fitted were considered very suitable by a Dunlop representative for clay workings and other similar operations but their suitability for normal roadwork was questioned. His opinions were borne out by the CM tests.

Stirrup steps The cab fitted on the vehicle is the standard Ford D series. NAM, however, has made a few alterations to compensate for the high cab ground clearance; one is to lower the headlights to a more reasonable height and the other is the introduction of stirrups to facilitate cab entry and exit. Despite the use of stirrups we still found some difficulty in entering and leaving the cab. The robust scow ended tipper body on the test vehicle was made by Booker Motor Bodies, also of Newton Abbot.

Site performance proved excellent, and our one main criticism of the vehicle can be placed squarely on the steering. With only 2+ turns from lock to lock, the steering is very sensitive and at first acqaintance with the vehicle on the road one is constantly having to make small corrections with the wheel. Steering effort I would not consider excessive for site work but a tight grip of the wheel was needed to prevent feedback from the front axle driving wheels deflecting the steering. With such a high steering ratio the reversibility effect of the steering is strong.

A reduction in length of the standard steering arm fitted to the Ford chassis was made necessary so that it did not foul the

made necessary so that it did not foul the front suspension mounting on the front axle of the converted vehicle. I understand from NAM that future models will incorporate a modified steering arm assembly to remedy the situation and increase the turns from lock to lock.

For the tests on normal roads the NAM /Ford was running at more than 1 ton below its plated gross weight — a result of relying on the loader's weight assessment of payload. For the quarry part of the trial many loads were carried, the average being 8 tons, which put the gross weight well over the 13 tons permitted on the road.

On-site performance

No fault could be found with the on-site performance in either rear-wheel or four-wheel drive, in the worst conditions we could find. The slimy, wet mud was about a foot deep and I tried hard to bog the vehicle down. Whenever I managed to do so with only rear axle drive engaged, a simple change to four-wheel drive had the laden Ford NAM moving out with no sign of effort — in many cases rear axle drive was sufficient, and four-wheel drive did not have to be used very often.

When on site, traversing deep tracks made by previous vehicles, the vehicle seemed to lurch from side to side, but this did not cause discomfort in the cab. When standing looking at the vehicle crossing these tracks the roll appeared more severe than it felt from the cab but the vehicle showed no lack of lateral stabiliity.

Normal road operation with the vehicle laden was marred by vibration both through the steering column and through the chassis with an accompanying road noise not dissimilar to the drone of a propeller-driven aircraft. These characteristics were attributed to the tyres fitted which are not designed for prolonged road use. Such use would prove fatiguing, especially in causing the wrists to ache.

No braking figures were taken, the road being too wet and greasy to give any real indication of the vehicle's capabilities, Use of brakes throughout the day's trial gave me no reason to doubt their performance, although again the choice of tyre is not ideal for optimum braking results on metalled surfaces.

More conversions

NAM engineers are confident that this first model will find a market and they intend to undertake further conversions on Ford tippers up to 16 tons gross.

There certainly seems to be a demand for the more hardy type of tipper specifically designed with a bias to site operation, yet conforming to C and U Regulations for occasional on-the-road use, and it is here the NAM's 4 x 4 version of the Ford might well find its niche at £5339.