PUNISHMENT for th,

Page 36

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

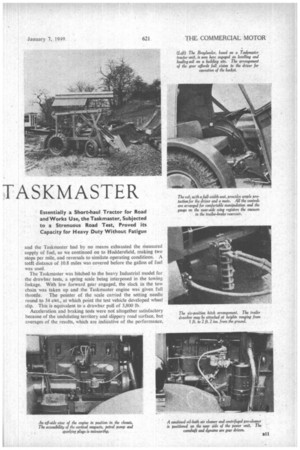

TASKMASTER

Essentially a Short-haul Tractor for Road and Works Use, the Taskmaster, Subjected to a Strenuous Road Test, Proved its Capacity for Heavy Duty Without Fatigue

By L. J. COTTON, M.I.R.T.E.

Y test of the latest Day,id Brown industrial tractor might be described as a case of the biter bit," for it was the turn of the Taskmaster to undefgo a gruelling—and it did so without flinching. It was taken over an exacting course over the Pennines, • and earned full marks for its untiring pulling in low gears.

With two independent braking systems, speedometer, lighting and all other detads required by the Road Traffic Act, the tractor was attached to a trailer for its trials, which were accomplished satisfactorily, and it showed notable economy in fuel consumption. The versatility of the prime mover was demonstrated during the day by an exhibition of soil moving and loading, Brayloader equipment being fitted to the basic tractor unit for this purpose.

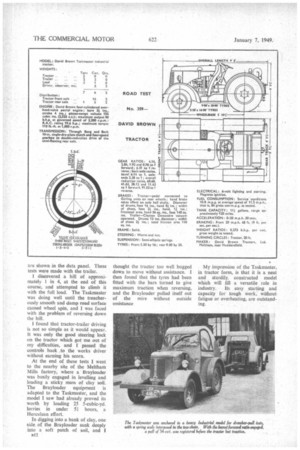

Overhead-valve Engine • The energetic power unit of this machine is a David Brown fourcylindered overhead-valve engine, which is of a modest capacity (2i litres) and develops 40 b.h.p. at the governed speed of 2,200 r.p.m. This unit is similar to that employed for the larger Industrial model, so that fitted to the smaller Taskmaster it • should have long life, with relatively small need for maintenance. As it forms part of the backbone • of the frame, the main crankcasecylinder-block casting is of generous proportions, and there is no lack of rigidity. It is equipped with renewable wet cylinder liners, oil-bath air , cleaner and centrifugal pre-cleaner. The crankshaft is retained in three wide white-metal shell bearings, and the big-end bearings are of similar construction.

• The camshaft and dynamo are gear-driven from the front of the crankshaft. Push-rods and rocker gear are employed in the operation of the valves. In the engine lubricaa 1 0 tion system full pressure fged is maintained to the crankshaft and crankshaft bearings and to the valve rocker shaft.

As part of the frame construction, the clutch housing fully encloses the friction member. A Borg and Beck single-dry-plate clutch of 10-in. diameter is used. The gearbox is a cast-iron structure 'housing straighttoothed gears for the forward and reverse speeds. Gearbox and axle share a common lubrication sump, and,..as usual in tractor practice, the gearbox mainshaft drives direct to the bevel gearing of the rear axle.

The bevel gearing affords a reduction ratio of 6.14 to 1, but a further reduction of 2.38 to 118 obtained by employing epicyclic gearing in the ends of the axle. The overall ratios provide a forward-speed range of 4-21.6 m.p.h. with the engine turning at governed speed.

In the braking system the pedal is connected mechanically toGirling units at the wheels, whilst the hand brake takes effect on internalexpanding shoes operating in drums attached to the axle half-shafts. Where used with a -1.7ctitim-braked trailer, the foot brake is also con

nected to an operating valve. A Clayton Dewandre' sYstem is employed.

Meltham, the birthplace of the Taskmaster, lies in a hollow on the fringe of the Pennines, so it was not difficult to find a course that would fully test the abilities of the tractor. I immediately headed towards the "Isle of Skye," a notable inn at the summit of the range of hills.

This provided a three-mile climb which enforced full use of intermediate gears. Third gear was engaged for the first two miles, and the road speed varied from 6-8 m.p.h., according to the gradient. Steeper inclines, towards the last mile of the climb, necessitated changing to second gear, and with full engine revolutions, the Taskmaster continued pulling steadily at 5-6 m.p.h This trial had lasted slightly over half an hour, and with the engine pulling at "full bore" the whole time, I expected the engine-oil temperature to be abnormally high. Nevertheless, it remained consistently at 140 degrees F., whilst the gearbox-axle lubricant registered a temperature of 105 degrees F. The cooling water settled down to a steady 173 degrees F., which I later found was 38 degrees above the normal service temperature.

Arduous Test Conditions In the shelter of the town, there was no wind, and the ambient temperature was 51 degrees F., but as we climbek it grew colder and the wind approached gale force. I was glad of the. shelter Of the Cab, especially in a fall ()train, when the temperature fell to 44 degrees F.

The consumption trials were started before reaching the summit, and for four miles we were running on reasonably give-and-take, territory. Then came the Sharp fall, including a 1-in-8 decline, into IVIeltharn, and the driver, Viking ,no chances, employed • inteiMicliate gear ratios.

A distance of six miles of the consumption test had been covered by the time we reached Meltham, and the Taskmaster had by no means exhausted the measured supply of fuel, so we continued on to Huddersfield, making two stops per mile, and reversals to similate operating conditions. A Mal distance of 10.8 miles was covered before the gallon of fuel was used.

The Taskmaster was hitched to the heavy Industrial model for the drawbar tests, a spring scale being interposed in the towing linkage. With low forward gear engaged, the slack in the tow chain was taken up and the Taskmaster engine was given full throttle. The pointer of the scale carried the setting needle round to 34 cwt., at which point the test vehicle developed wheel slip. This is equivalent to a drawbar pull of 3,800 lb.

Acceleration and braking tests were not altogether satisfactory because of the undulating territory and slippery road surface, but averages of the results, which are indicative of the performance, are shown in the data panel. These tests were made with the trailer.

I discovered a hill of approximately 1 in 4, at the end of this course, and attempted to climb it with the full load. The Taskmaster was doing well until the treacherously smooth and damp road surface caused wheel spin, and I was faced with the problem of reversing down the hill.

I found that tractor-trailer driving is not so simple as it would appear. It was only the good steering lock on the tractor which got me out of my difficulties, and I passed the controls back to the works driver without earning his scorn.

At the end of these tests I went to the nearby site of the Meltham Mills factory, where a Brayloader was busily engaged in levelling and loading a sticky mass of clay soil. The Brayloader equipment is adapted to the Taskmaster, and the model I saw had already proved its worth by loading 25 5-cubic-yd. lorries in under 51 hours, a Herculean effort.

In digging into a bank of clay, one side of the Brayloader sank deeply into a soft patch of soil, and I Is12 thought the tractor too well bogged down to move without assistance. I then found that the tyres had been fitted with the bars turned to give maximum traction when reversing, and the Brayloader pulled itself out of the mire without outside assistance My impression of the Taskmaster, in tractor form, is that it is a neat and sturdily. constructed model which will fill a versatile role in industry. Its easy starting and capacity for tough work, without fatigue or overheating, are outstanding.