Crane Fruehauf goes into splendid insulation

Page 48

Page 49

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

Steve Gray looks into the state of the art of insulated tanker design

'OU CAN'T mistake a Crane .ruehauf insulated tanker. It's listinctive looks distinguish it rom the rest of the field. But the hap e owes nothing to a deigner's stylistic whim.

The insulated tankers are haped as they are for practical easons as I discovered when I isited CF at Dereham in Norfolk. Chief development and reearch engineer Geoff Cannon xplained how the tankers are -lade and how the final design as achieved.

As you might expect, one of le biggest problems is heat loss either direction (a load which heds heat getting cold or a cold Dad warming up).

Most insulated tanker makers imply follow the shape of the 3nk — be it round or elliptical — with thin insulation material and 3rget about the mountings. But -lose are a major source of temerature loss especially when le vehicle is moving and has an ir stream passing over it.

To combat this, CF fits a longiadinal side frame which encomasses the mountings. The tank barrel itself has steel rings welded round its circumference at intervals and insulation material is added between these, so the mountings are insulated as well.

A 51mm (2in) thick section is applied first and it is followed by a 25mm (1n) layer which is overlapped on the barrel rings. Not only does this insulate the rings, it also allows the cladding to be fitted without the danger of fretting.

Once the insulation is applied, the outer cladding is fitted. This is either stainless steel, grp or aluminium, depending on the requirements of the customer.

One edge of the 1295mm (51in)-wide strake, or panel, is riveted along the longitudinal rail. The panel is then stretched over the barrel and handwinched to compress the insulation over the rings slightly. It is then riveted to the other side rail.

Each strake is thus fitted in turn, with a 76mm (3in) overlap between each of the panels. A flexible water sealant is a between panels, but there is no riveting of one to another.

This, Geoff explained, is because a tank with a very hot cargo can expand or grow by up to 38mm (1.5in) overall. If the sections were riveted the 6.4mm (0.25in) movement of each would soon loosen them, and to allow movement of the longitudinal rails, expansion joints are incorporated. The entire tanker is thus not too highly stressed and it can expand or contract without any strain.

For the front and rear, specially formed caps are used. The tanks themselves are built from either carbon or stainless steel — alloy is too expensive, expands too much, and is weakened more quickly.

The rings are made from the same material as the tank itself, and usual practice is to have stainless steel cladding with stainless sheet barrel and alloy or grp with aluminium.

Most UK tanks are 3mm (0.121n) thick while for international work the thickness is 5mm (0.2in), although this latter specification is also used for bitumen work in Britain.

For the cladding, 18-gauge al Left: Standard CF trailer running gear is used on all tanks, insulated or not.

ay is used for the sides with 14gauge ends — twenty-two lauge stainless steel is also J sed but obviously such a tank .....osts more — but stainless steel s essential for transporting food stuffs and drink.

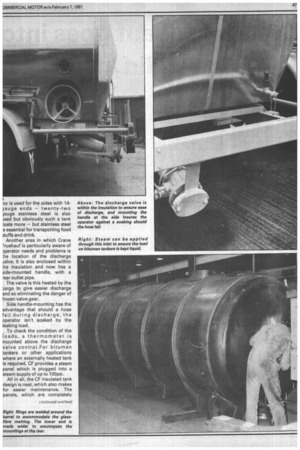

Another area in which Crane :ruehauf is particularly aware of )perator needs and problems is :he location of the discharge ralve. It is also enclosed within :he insulation and now has a side-mounted handle, with a rear outlet pipe.

The valve is this heated by the -..:argo to give easier discharge and so eliminating the danger of Frozen valve gear.

Side handle-mounting has the advantage that should a hose fail during discharge, the operator isn't soaked by the leaking load.

To check the condition of the (clads, a thermometer is mounted above the discharge valve control.For bitumen tankers or other applications where an externally heated tank is required, CF provides a steam panel which is plugged into a steam supply of up to 100psi.

All in all, the CF insulated tank design is neat, which also makes for easier maintenance. The panels, which are completely dyeatherproof, seal the glassfibre matting but are easily replaced if damaged — a new section is simply put over the :op of both its neighbours to avoid the need to remove every strake. But CF says this should Pe carried out by one of its serlice centres.

The CF system of tank insulaion is claimed to provide very ligh standards of heat retention, Put there are no BSI or ISO stanlards which are applied to tank nsulation, and none are immi Heat loss is to a degree dePendent on movement, but durng tests on stationary vehicles, rom a fairly high initial temperaure CF has recorded losses of /.5°F per hour over nine hours.

A tanker filled with water at 20°F lost as little as 0.1°F in an lour, but a more realistic loss, ays Geoff, and one which vould be acceptable, is a maxinum of 1° an hour.

I asked Geoff if CF had ever teen asked to fit refrigeration to :s tanks. Largely unnecessary, replied, as the products cared were never that temperaJre-critical and an insulated ank was more than capable of laintaining a required tempera Round tanks are used for liquids such as bitumen where a certain amount of pressurisation is required, but an elliptical shape is used on non-pressurised tanks. These too can be insulated, but are invariably only partly so for products such as heavy fuel oil where the lower section must be kept warm.

Crane Fruehauf builds around 150 insulated tanks during a normal year which constitutes about a third of its total tank production. It has virtually cornered the bitumen market, and makes about 80-90 out of its 150 tanks for this type of operation.