Purpose-built trailers for Nitrovit

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

by Gordon Murray

THAT part of the Diseases of Animals (Waste Food) Order 1973, which covers the transport of offals requires that vehicles built for that purpose should be drip proof, covered, and enclosed with material capable of being cleaned and disinfected.

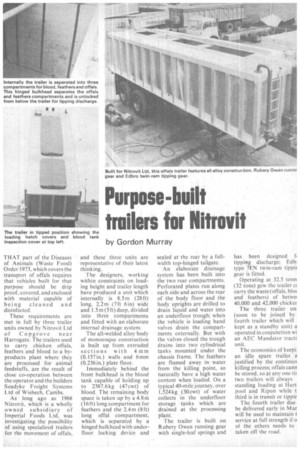

These requirements are met in full by three trailer units owned by Nitrovit Ltd of Copgrove near H arrogate. The trailers used to carry chicken offals, feathers and blood to a byproducts plant where they are processed for animal feedstuffs, are the result of close co-operation between the operator and the builders Seadyke Freight Systems Ltd of Wished'. Cambs.

As long ago as 1968 Nitrovit, which is a wholly owned subsidiary of Imperial Foods Ltd, was investigating the possibility of using specialized trailers for the movement of offals, and these three units are representative of their latest thinking.

The designers, working within constraints on loading height and trailer length have produced a unit which internally is 8.5m (28ft) long, 2.2m (7ft 6in) wide and 1.5 m (5ft) deep, divided into three compartments and fitted with an elaborate internal drainage system.

The all-welded alloy body of monocoque construction is built up from extruded sections with 4 mm (0.1571n.) walls. and 6mm (0.236 in.) plate floor.

Immediately behind the front bulkhead is the blood tank capable of holding up to 2387.6 kg (47 cwt) of blood. The remaining body space is taken up by a 4.8m (16ft) long compartment for feathers and the 2.4m (8ft) long offal compartment, which is separated by a hinged bulkhead with underfloor locking device and sealed at the rear by a fullwidth top-hinged tailgate.

An elaborate drainage system has been built into the two rear compartments. Perforated plates run along each side and across the rear of the body floor and the body uprights are drilled to drain liquid and water into an underfloor trough; when the vehicle is loading hand valves drain the compartments externally. But with the valves closed the trough drains into two cylindrical tanks mounted under the chassis frame. The feathers are flumed away in water from the killing point, so naturally have a high water content when loaded. On a typical 40-mile journey, over 1,524kg (30cwt) of water collects in the underfloor storage tanks which are drained at the processing plant.

The trailer is built on Rubery Owen running gear with single-leaf springs and has been designed fi tipping discharge; Edb] type 7EN twin-ram tippil gear is fitted.

Operating at 32.5 tonn (32 tons) gcw the trailer carry the waste (offals, blot and feathers) of betwel 40,000 and 42,000 chicker The three trailer um (soon to be joined by fourth trailer which will kept as a standby unit) a operated in conjunction wi an AEC Mandator tracti unit.

The economics of keepi. an idle spare trailer a justified by the continuo killing process; offals cann be stored, so at any one tir two trailers will always standing loading at Hart pool and Ripon while t third is in transit or tippir The fourth trailer due be delivered early in Mar will be used to maintain t service at full strength if o of the others needs to taken off the road.