Carrimore Introduces Simple Detachable Rear Axle

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

Securing Plate Which Unlocks When Lifted. Removal a 5 minute Operation AVISIT to Carrimore Six Wheelers, Ltd., North Finchley, London, N.12, rarely fails to produce something of interest, as the concern is always seeking to simplify and improve its existing designs of trailer and semitrailer.

The latest move in this direction. is the introduction of a new type of detachable rear axle for application to the concern's low-loading semi-trailers. The basis of the design lies in mounting the pins in the rear end of the springs in substantial cradles which are designed to slide into the tail end of the channel-section extension of the main frame of the semi-trailer chassis.

These cradles are located forward by an abutment electrically welded into the channel, and are restrained from upand-down movement by guide pieces, welded to the channel at such a height as to form a sliding fit for tongue pieces on the base of the cradles.

Locking Mechanism

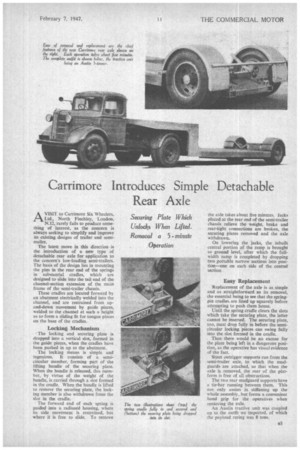

• The locking and securing plate is dropped into a vertical slot, formed in the guide pieces, when the cradles have been pushed in up to the abutment.

The locking means is simple and ingenious. It consists of a semicircular member, forming part of the lifting handle of the securing plate. When the handle is released, this member, by virtue of the weight of the handle, is carried through a slot formed in the cradle. When the handle is lifted to remove the securing plate, the locking member is also withdrawn from the slot in the cradle.

The forward end of each spring is guided into a radiused housing, where its side movement is restrained, but where it is free to slide. To remove the axle takes about five minutes. Jacks placed at the rear end of the semi-trailer chassis relieve the weight, brake and rear-light connections are broken, the securing plates removed and the axle withdrawn.

On lowering the jacks, the inbuilt central portion of the ramp is brought to ground level, after which the fullwidth ramp is completed by dropping two portable narrow sections into position—one on each side of the central section

Easy Replacement

Replacement of the axle is as simple and as straightforward as its removal, the essential being to see that the springpin cradles are lined up squarely before attempting to push them home.

Until the spring cradle clears the slots which take the securing plate, the latter cannot be inserted. The securing plate, too, must drop fully in before the semicircular locking pieces can swing fully into the slot formed in the cradle.

Thus there would be no excuse for the plate being left in a dangerous position, as the operative has visual evidence of the fact.

Stout outrigger supports run from the semi-trailer axle, to which the mudguards are attached, so that when the axle is removed, the rear of the platform is free of all obstructions.

The two rear mudguard supports have a tic-bar running between them. This not only assists in stiffening up the whole assembly, but forms a convenient hand grip for the operatives when rertioving the axle.

An Austin tractive unit was coupled up to the outfit we inspected, of which the payload rating was 8 tons.