For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OF TEN SHILLINGS is awarded each weeh to the sender ef the best letter which we publish, on this page ; all others are paid for at the rate of a penny a line, with an allowance for photographs All *des are edited before .being published. Mention your employer's name, in confidence, as evidence of good faith, Address, 1)., 31. and P., " The Commercial Motor," 7-15, Rosebery Avenue, London, E.G. 1.

Lamps Alight— Light your lamps at 5.35 in London, 6.2 in Edinburgh, 5.32 in Newcastle, 5.42 in Lives-pool, 5.40 in Birmingham, 5.45 in Bristol, and 6.26 in Dublin.

A Few Notes on Locknuts.

The sender of the following communication has been awarded the 10s. prize this week.

[1826] " (H. M. S. " Chatham ") writes :—" It

is remarkable how very few of the hundred-and-one locknut devices on the market are employed in general motive power engineering. It is quite probable for most cases the patent locknut .devices are not so much superior to the plain locknut as to warrant the extra expense entailed, and in any case the necessity for locknut S far muchmechanical work is over-estimated.

"It would be interesting tehave your 'D., M. and F.' readers' experiences in this connection. Even where a bolt or stud is .subject to violent vibration, the nut and locknut, if properly screwed up tightly ori an unyielding body, are little liable to slack back. Failure to hold is generally through carelessness in the first'instance.

"A case in point is in the nuts of bolts where the sharp edges of the bolt holes are not rounded off to accommodate the head. All bolts •have a fillet or radius where the shank meets the head, and this is often responsible for careless assembling. The bolt holes should be radiused ' to correspond, but this is quite commonly neglected, notably in pipe flanges ; so that'll. bolt might easily be screwed up tight and yet only be bearing on this radius at the sharp edge of the bolt hole and net on .the head of the bolt. With vibration the strain on the bolt soon causes the radius to find its bed on the edge of the hole by bruising it out, whence the nut soon becomes slack.

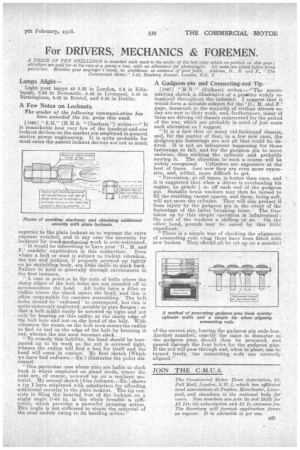

" To remedy this liability, the head should be hammered up to its work as the nut is screwed tight, whence the radius will find a bed for itself and the head will come in contact. My first sketch [Which we have had redrawn.—ED.1 illustrates the point discussed.

"One particular case where nuts are liable to slack back is where employed on gland studs, where the nuts are, of course, screwed up on a resilient material. My second sketch [Also redrawn.---En.] shows a tip I have erfiriloyed with satisfaction for affording 'additional security to the plain locknut. The tip consists in filing the bearing free of the locknut on a slight angle (1-64 in, in the whole breadth is sufficient), which provides a powerful jamming action. This angle is not sufficient to strain the •material of the stud unduly owing to its bending action."

A Gudgeon-pin and Connecting-rod Tip.

11827] "M.II(.". (Fulham) writes :—" The accompanying sketch ,is illustrative of a practice widely recognized throughout the industry. I suggest that it would form a suitable subject for the `D., M. and.F.' page, inasmuch as-the majority of civilian driver's today are new to their work, and, furthetmore, many of them are driving old chassis resurrected for the period of the war, which are probably in need of just some such alteration as I suggest. "It is a fact that on many old-fashioned chassis, and, for the matter of that, in a few 1.10i ones, the gudgeon-pin fastenings are not all that could be desired. It is not an -infrequent happening for these fastenings to fail, and for the gudgeon pin to move endwise, thus striking the cylinder and probably scoring it. The objection to such a course will be widely recognized. Cylinders are expensive at the best of times. Just now they are even more expensive, and, withal, snore difficult to get. " Prevention, at all times, is better than cure, and it is suggested that when a driver is overhauling his engine, he grinds in. off -each end of the gudgeon pin. Suitable brass washers may then be turned to fill the resulting vacant spaces, and these, being soft, will not score the cylinder. They will also protect it from injury by the gudgeon pin in the event a the fastenings of the latter breaking loose. The time taken up by this simple operation is infinitesimal ;

the cost of the washers a shilling or so. On the other hand, pounds may be saved by this little expedient.

" There is a simple way of checking the alignment of connecting rods when these have been fitted with new hushes. They should all be setup on a mandrel

of the correct size, leaving the gudgeon pin ends free. Another mandrel, exactly the same in diameter as the gudgeon pins, should then be procured, and passed through the four holes for the gudgeon pins. If the rod will pass through and, when in place, can be turned freely, the connecting .rods are correctly aligned."