WORKSHOP

Page 129

Page 130

Page 131

If you've noticed an error in this article please click here to report it so we can fix it.

/ The Renault Master was introduced in 1981, and caused quite a stir among British van buyers at the time. Apart from its rather unconventional looks, the Master was unusual for a 3.5-tonne van in having front wheeldrive when virtually all competitors had drive going to the rear wheels (though just to confuse matters, the chassis-cab version of the Master did feature rear-wheel drive).

The Master came with both petrol and diesel engines, and in a number of variants including the choice of long-wheelbase and high-roof versions. The front-wheel-chive layout afforded a particularly low floor in the load area, and after a fairly slow sales start, the Master soon became popular with certain users, notably the replacement window companies.

Since its launch, the Master has remained fundamentally unchanged, though this year saw minor changes to the interior, as well as the option of a more powerful turbocharged direct-injection diesel engine.

As the sales of Renault vans such as the Master, Trafic and Extra have increased, so has the company's awareness of the needs of the market, and in recent years Renault has developed a network of specialist van dealers to serve its customers. We were therefore pleased to attend a service on a Master at one of these dealers — in this case, Renault London in Western Avenue. Fitter Peter Bolter, led us through the service, and finds the vehicle presents no particular problems.

by Peter Watt

/The Workshop ways in October featured the Leyland Daf 95-Series, caption 19 showing a small gauze filter fitted inside a banjo bolt. We incorrectly said the bolt held the pipe between the fuel filter and the injection pump. In fact it secures the fuel pipe from the tank to the priming pump. Failure to clean this filter could lead to fuel blockage. Our thanks to Michael Hustler for bringing the error to our attention. Our service is on a B-registered Master with the two-litre petrol en gine. Like many Masters it has been converted into a community

minibus — the body on our vehicle was by Atlas Conversions of Portsmouth — and had covered a modest 30,600km (19,100 miles). Its owners had reported it to be running extremely roughtly, and had therefore submitted it early for its 38,6001cm (24,000-mile) check.

Petrol-engined Masters have an A service every 9,600km (6,000 miles), with a larger B service every 48,000km (30,000 miles). The standard time for an A service is 1.5 hours, excluding additional time for replacing worn parts such as brake pads.

2 The Master is a semi-forward control van, which means that the engine is positioned roughly under the driver in the centre of the van. Access to the power unit is therefore through a panel in the cab floor, and this means that for any major work the passenger seat must be unbolted and removed to allow decent access. The next step is to unclip the main cover to reveal the top end of the engine. While older Masters have an inspection hatch in the engine cover to let the operator do basics like checking the oil level, the latest vans have a one-piece cover meaning that the whole cover must be taken off even for a simple job like looking at the dip-stick.

3 From the description of the engine's rough running fitter Peter Bolter predicted an electrical problem, and first set about removing the spark plugs and the distributor (only more recent petrol Masters have electronic ignition). To get at the plugs, Bolter finds it preferable to remove the intake trunking from above the nearside of the engine to give a bit more room and to protect the trunking from damage. On inspection, the plugs didn't seem in bad condition, but Bolter replaced them just in case. He also spotted that the advance/retard pipe to the manifold on the offside of the engine was split and also needed changing. 4 Before removing the distributor, Bolter paused to point out another potential cause of poor running which can be difficult to spot. When taking off the engine cover, it is easy to knock off the wire to an electric slow-running switch on the side of the carburettor (see above), thus preventing the engine from idling properly; care should therefore be taken whenever the cover is removed or replaced that the wire has not been damaged.

Bolter also took the precaution of disconnecting the battery under the bonnet flap before attempting to reach the distributor, to remove the possibility of a spanner shorting out against the starter motor.

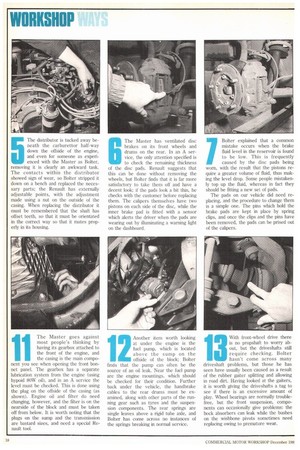

5 The distributor is tucked away beneath the carburettor half-way down the offside of the engine, and even for someone as experienced with the Master as Bolter, removing it is clearly an awkward task. The contacts within the distributor showed sign of wear, so Bolter stripped it down on a bench and replaced the necessary parts; the Renault has externally adjustable points, with the adjustment made using a nut on the outside of the casing. When replacing the distributor it must be remembered that the shaft has offset teeth, so that it must be orientated in the correct way so that it mates properly in its housing. GThe Master has ventilated disc brakes on its front wheels and drums on the rear. In an A service, the only attention specified is to check the remaining thickness of the disc pads. Renault suggests that this can be done without removing the wheels, but Bolter finds that it is far more satisfactory to take them off and have a decent look; if the pads look a bit thin, he checks with the customer before replacing them. The calipers themselves have two pistons on each side of the disc, while the inner brake pad is fitted with a sensor which alerts the driver when the pads are wearing out by illuminating a warning light on the dashboard.

Bolter explained that a common mistake occurs when the brake fluid level in the reservoir is found to be low. This is frequently caused by the disc pads being worn, with the result that the pistons require a greater volume of fluid, thus making the level drop. Some people mistakenly top up the fluid, whereas in fact they should be fitting a new set of pads.

The pads on our vehicle did need replacing, and the procedure to change them is a simple one. The pins which hold the brake pads are kept in place by spring clips, and once the clips and the pins have been removed, the pads can be prised out of the calipers.

BReplacing the disc pads simply requires reversing the procedure for removing them, but it helps to push the pistons back into the caliper before inserting the pads to give the necessary room.

Before moving on, Bolter pointed out another misunderstanding which can result when a pad does wear down to the sensor (as on the example shown above). When this happens, not only does the brake warning light illuminate the dash, but also the oil pressure light. In this instance, however, the oil pressure light only serves to warn the driver of a hazard, and does not indicate that there is a problem with the oil supply or its sensors.

9 In an A service, it is not specified to check the linings on the rear drum brakes unless the customer requires it. If it is necessary, inspection holes are provided in the drums, but as with the front brakes, Bolter prefers to remove the wheel just to make sure (the handbrake shoe is thinner than the leading shoe which makes judging the rates of wear difficult). Since the front brakes do most of the work, the rear linings generally last around 64,000km (40,000 miles) and don't need much attention. The drums are fitted with automatic adjusters, which work when the handbrake is applied, and which keep the shoes in position relative to the drum.

With the vehicle up in the air, the next stop is to attend to the checks underneath. The fan belt is located at the rear of the engine, the belt on our vehicle was beginning to crack in places and needed replacing. Fitting a new one is simply a matter of slackening off the arm holding the alternator, then slipping the replacement belt into place. Bolter recommended checking the tension of the belt a couple of thousand miles after fitment in case it had stretched. While under the engine it's worth having a kmk for any water or oil leaks, as well as examining the various pipes and hoses for condition and security.

11

The Master goes against most people's thinking by having its gearbox attached to the front of the engine, and the casing is the main component you see when opening the front bonnet panel. The gearbox has a separate lubrication system from the engine (using hypoid 80W oil), and in an A service the level must be checked. This is done using the plug on the offside of the casing (as shown). Engine oil and filter do need changing, however, and the filter is on the nearside of the block and must be taken off from below. It is worth noting that the plugs on the sump and the transmission are bastard sizes, and need a special Renault tool. Another item worth looking at under the engine is the fuel pump, which is located above the sump on the offside of the block; Bolter finds that the pump can often be the source of an oil leak. Near the fuel pump are the engine mountings, which should be checked for their condition. Further back under the vehicle, the handbrake cables to the rear drums must be examined, along with other parts of the running gear such as tyres and the suspension components. The rear springs are single leaves above a rigid tube axle, and Bolter has come across no instances of the springs breaking in normal service. With front-wheel drive there is no propshaft to worry about, but the driveshafts still require checking. Bolter hasn't come across many driveshaft problems, but those he has seen have usually been caused as a result of the rubber gaiter splitting and allowing in road dirt. Having looked at the gaiters, it is worth giving the driveshafts a tug to see if there is an excessive amount of play. Wheel bearings are normally troublefree, but the front suspension, components can occasionally give problems: the hock absorbers can leak while the bushes on the wishbone pivots sometimes need replacing owing to premature wear. Regular drivers of the Master will be familiar with the rather sloppy feeling of its gearlever, not only in the neutral position, but also when the lever is in gear. In extreme cases this can present gear selection problems, and Bolter explained that this is caused by wear in the plastic bush where the gear lever pokes through a hole in the gear selector rod (shown above). The offending bush is to be found on the selector rod which is just to the offside of the vehicle above the transmission casing.

There is no lubrication to be done before lowering the vehicle again, for the Renault has no grease points. There is not much to be found under the front bonnet panel of the Master apart from the air filter, the battery and various fluid reservoirs. The air filter housing is on the offside of the vehicle, and to replace the element (which is done every 19,300km/12,000 miles) you first need to move the windscreen washer reservoir which is held in place by a single nut. With the reservoir out of the way, the filter — which is a largish cylindrical element — can be manoeuvred into position. The battery is on the nearside, and with winter approaching, it received a thorough overhaul on our vehicle. The last item in the service is to tune the engine so that it is set up to perform efficiently. Renault dealers have purpose-built diagnostic equipment to enable them to do this, and the Master engine has a socket at the front of the block to connect it to the terminal; a clip is also attached to one of the high-tension leads. The screen display takes the fitter through a pre-programmed sequence of steps, and the dwell angle, timing, mixture strength and so on can be adjusted as indicated. Having optimised all the settings, the vehicle is taken out for a test drive to ensure that it behaves properly on the road.