Molten Metal by Road

Page 70

If you've noticed an error in this article please click here to report it so we can fix it.

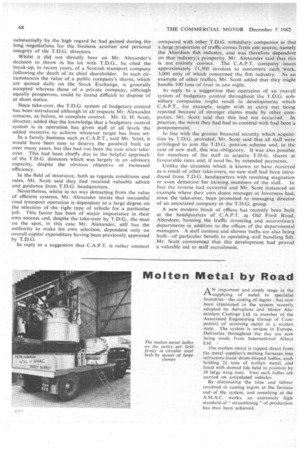

AN important and costly stage in the supplying of metal to specialist foundries—the casting of ingots—has now been eliminated in the system recently adopted by Aeroplane and Motor Aluminium Castings' Ltd. (a member of the Associated Engineering Group of Companies) of receiving metal in a molten state. The system is unique in Europe. Deliveries throughout the day are now being made from International Alloys Ltd.

The molten metal is tapped direct from the metal supplier's melting furnaces into refractory-lined drum-shaped ladles, each holding 21 tons of molten metal, and fitted with domed lids held in position by 10 large wing nuts. Two such ladles are carried on articulated vehicles.

By eliminating the time and labour involved in casting ingots at the furnace end of the system, and remelting at the A.M.A.C. works, an extremely high standard of " streamlining " of production has thus been achieved.