DENNIS INTRODUCES A 12-T r RIGID SIX-WHEELED OILER

Page 30

Page 31

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

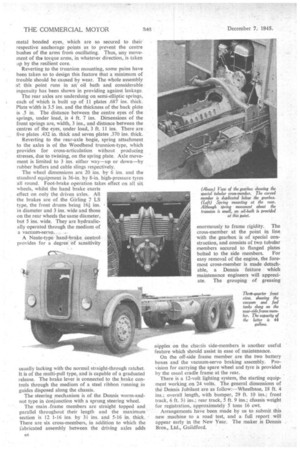

THE latest addition to the range of Dennis vehicles is a rigid six-wheeled, oil-engined 12-tonner, to which the maker has given the name Of Jubilant. A close examination of the chassis reveals the fact that it is a machine designed and built to perform its specific duty with a generous margin in respect of strength and engine power, rather than as a vehicle making an appeal from the low initial-cost point of view

It is powered by a six-cylindered direct-injection oil engine, known as the 06, a f Lilly detailed description of which was given in our issue dated June 29 last. The cylinder bore is 150 mm. and the stroke 146 mm., the swept cylinder volume thus being 7.5R litres.

The Treasury rating is 41.04 h.p. and the power curve shows 100 b.h.p. at the governed speed of 1,800 r.p.m. Maximum torque is 330 Lb-ft. at 1,100 r.p.rn. Wet-type liners . are used in the cylinder block; these have been found to offer excellent resistance to wear as the Maximum shown on any one liner after running the equivalent of 175,000 road miles was 0.01025 in.

A Toceo-hardened, seven-bearing crankshaft is fitted, the total projected area of the seven bearings

being 47.7 sq. ins. The big-ends of the chromemolybdenum connecting rods are split diagonally to enable the pistons and rod assemblies to be withdrawn from above The cylinder heads, on the combustion side, are flat, but in each piston there is a toroidal cup formed in the crown, a combustion system which more or less localize: the primary burning processes. There are two air inlervalves and two exhaust valves per cylinder, the inlet port diameter being 1 5-16 ins., and the exhaust 1 1-16 ins.

Large-diameter hollow tappets operate the push rods, the camshaft, which is mounted in four bearings, being at a high level on the off side of the cylinder block. The Dennis exhauster pump, dynamo and water pump are mounted in line on the near side of the engine and are driven at 14 times engine speed. Also on the near side are the fuel-lifting pump and the injection pump which are driven at half engine speed.

The engine is rubber-mounted in the chassis—at the rear end on trunnions secured to the frame members and, forward, on cradles so disposed as to give a floating effect.

From the engine, the drive is taken through a twoplate dry clutch having a friction area of 429 sq. ins. and provided with an adjustable stop, to a five-speed overdrive gearbox. The latter is so mounted that a straight-through shaft can be used from the gear lever to the selector box.

The gearbox ratios are:—overdrive, 0.69 to 1; fourth, 1 to 1; third, 1.66 to 1; second, 2.94 to 1; and first, 5.18 to 1; the reverse ratio is 6.66 to 1. In the case of the overdrive ratio, this gear can be pre-selected, the change being made merely by declutching. From the main gearbox, there is a short Layrub-jointed shaft running to a two-speed auxiliary box, which is bolted to one of the chassis cross-membeis.

This box, which is particularly robust, is of the con

stant-mesh type, and provides for a reduction of 1.396 to 1. The control for this box is also direct, and terminates in a lever arranged to the left and rear of the driver. The estimated torque on this box is 1,600 lb-ft.

From the auxiliary box to the first driven axle, the drive is by a Hardy Spicer shaft (series 1,600) with needle-roller bearings, a similar type of shaft, but of smaller capacity (series 1,500), running between the two axles. The latter are of the overhead worm-driven type, the forward axle incorporating a third differential to equalize the driving torque. The standard rear-axle reduction is 8.25 to 1, and, with this, an overall range of ratios from 5.70 to 1 to 59.60 to 1 is available. The • alternative back-axle ratio provides for a reduction of 7.25 to I. An interesting fea ture of the rear bogie is the use of a fabricated assembly between the main frame members, to which the torque reaction arms are anchored. This substantial structure is carried down to form the mounting base for the cross shaft, which is carried beyond the mounting to form trunnions for the rear springs.

Each of the torque arms has rubbLr4c

metal bonded eyes, which are so secured to theirrespective anchorage points as to prevent the centre bushes of the arms from oscillating, Thus, any movement of the torque arms, in whatever direction, is taken oP by the resilient core.

Reverting to the trunnion mounting, some pains have been taken so to design this feature that a minimum of trouble should be caused by wear. The whole assembly at this point runs in an oil bath and considerable ingenuity has been shown in providing against leakage.

The rear axles are underslung on semi-elliptic springs, each of which is built up of 11 plates .687 ins. thick. Plate width is 3.5 ins, and the thickness of the back pla;te is .5 in. The distance between the centre eyes of the springs, under load, is 4 ft. 7 ins. Dimensions of the front springs are, width, 3 ins., and distance between the centres of the eyes, under load, 3 ft. 11 ins. There are live plates .432 in. thick and seven plates .370 ins. thick.

Reverting to the rear-axle bogie, spring attachment to the axles is of the Woodhead trunnion-type, which provides for cross-articulation without producing stresses, due to twisting, on the spring plate. Axle movement is limited to 3 ins, either way—up or down—by rubber buffers and cable slings respectively.

The wheel dimensions are 20 ins. by 6 ins, and the standard equipment is 36-in. by 8-in, high-pressure tyres all round. Foot-brake operation takes effect on all siX wheels, whilst the hand brake exerts effect on only. the driven axles. All the brakes are of the Girling 2 LS

type, the front drums being 161 ins. in diameter and 3 ins, wide and those on the rear wheels the same diameter, but 5 ins. wide. They are hydraulically operated through the medium of a vacuum-servo.

A Neate-type hand-brake. control.: provides for a degree of sensitivity usually lacking with the normal straight-through ratchet. It is of the multi-pull type, and is capable of a graduated release. The brake lever is connected to the brake controls through the medium of a steel ribbon running in guides disposed along the chassis.

The steering mechanism is of the Dennis worm-andnut type in eonjunction with a sprung steering wheel.

The main -frame members are straight topped and parallel throughout" their length and the maximum section is 12 1-16 ins. by 3i ins. and 5-16 in. thick. There are six cross-members, in addition to which the fabricated assembly between the driving axles adds rt6 enormously to frame rigidity. The cross-member at the point in line with the gearbox is of special construction, and consists of two tubular members secured to flanged plates bolted to the side members. For easy removal of the engine, the foremost cross-member is made detachable, a Dennis feature which maintenance engineers will appreciate. The grouping of greasing nipples on the chaesis side-members is another useful feature which should assist in case of maintenance.

On the off-side frame member are the two battery boxes and the vacuum-servo braking assembly. Provision for carrying the spare wheel and tyre is provided by the usual cradle frame at the rear.

There is a 12-volt lighting system, the starting equipment working on 24 volts. The general dimensions of the Dennis Jubilant are as follow:—Wheelbase, 18 ft. 4 ins.; overall length, with bumper, 29 ft. 10 ins.; front track, 6 ft. 31 ins.; rear track, 5 ft. 9 ins.; chassis weight for registration, approximately 5 tons 16 cwt.

Arrangements have been made by us to submit this new machine to a road test, and a full report will appear early in the New Year. The maker is Dennis Bros., Ltd., Guildford_