WAYS AND MEANS.

Page 73

If you've noticed an error in this article please click here to report it so we can fix it.

Repairing Leaky Radiator .

• Tubes.

ALEKAY radiator is an irritating defect in any bus or lorry, being unsightly and easily noticed by the general public. It is also comparatively expensive to repair, owing to the cost of dismantling and rebuilding the radiator and testing after repair. It is a common occurrence for tubes to be replaced and yet leak again after a few months' service. This is largely due to the difficulty in making the new solder adhere properly to the core plates, which are usually from A. in. to is, in. thick. Most failures of replaced tubes, when examined, show that the solder has made a good joint with the tube, but water leaks under the solder and runs down the outside of the tube.

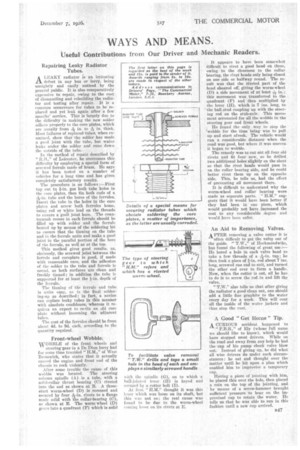

In the method of repair described by " MR.." of Leicester, he overcomes this difficulty by employing a special form of screwed ferrule made of brass. He says it has been tested on a number of vehicles for a long time and has given completely satisfactory results.

The procedure is as follows :—First tap out to fin, gas both tube holes in the core plates, then tin both ends of a A-in. tube and the bores of the ferrules. Insert the tube in the holes in the core plates and screw both ferrules home, using red or white lead on the threads to ensure a ko6a joint here. The countersunk recess in each ferrule should be filled up with solder and the ferrule heated up by means of the soldering bit to ensure that the tinning on the tube and in the ferrule unite and make a good joint in the parallel portion of the bore of the ferrule, as well as at the top.

This method gives good results, as, obviously, the screwed joint between the feriefle and coreplate is good, if made with reasonable care, and the adhesion of the solder to the tube and ferrule is somel, as both surfaces are clean and freshly tinned ; in addition the tube is supported for at least the fin, depth of the ferrule.'

The tinning of the ferrule and tube is quite easy, as is the final soldering-lip as described: in fact, a novice can replace leaky tubes in this manner with absolute confidence, whereas it requires an expert to re-tin an old core plate without loosening the adjacent tubes.

The cost of the ferrules should be from about 4d. to 9d. each, according to the quantity required.

Front-wheel Wobble. 'WOBBLE of the front wheels and steering-gear-in a De Dion lorry had for some time troubled " ELM.," of West Bromwich, who states that it actually enueed the engine and front end of the chassis to rock violently.

After some trouble the cause of this wobble was located. The steering column spindle (A) is a tube, with a solid-collar thrust bearing (C) riveted into the end as shown at B. A three. start worm-wheel (D) is recessed and secured by four -prin. rivets to a flange made solid with the collar-bearing (C), as shown at E. The worm wheel (D) gears into a quadrant (F) which is solid with the ;spinclic (G), on to which a hall-jointed lever (H) is keyed and secured by a cotter bolt (1).

At first " 11.M." thought it was this lever which was loose on its shaft, but thits was not so; the real cause was found to he due to the worm-wheel coming loose on its rivets at E.

It appears to have been somewhat difficult to rivet a good head on these, owing to the closeness to the collar bearing, the rivet heads only being closed on one side or halfway round. The result was that the riveted part of the head sheared off, giving the worm-wheel (D) a aide movement of at least 1.16in.; this movement was transferred to the quadrant (F) and then multiplied by the lever (H), which is 7 ins, long, to the ball stud coupling up with the steering rod on the stub-axle. This movement accounted for all the wobble in the steering gear and front wheels.

He found the only way to stop the /wobble for the time being was to pull up and start afresh. The vehicle would run a considerable distance when the road was good, but where it was uneven it began to wobble.

The remedy was to cut out all four old rivets and fit four new, so he drilled two additional holes slightly on the slant so that the rivet heads would pass in on the collar bearing side, and he could better rivet them up on the opposite side. This, he tells us, had the effect of preventing all movement there.

It is difficult to understand why the worm-wheel and collar bearing were made as separate parts. " H.M." suggests that it would have been better if they had been in one piece, which would probably not have increased the cost to any considerable degree and would have been safer.

An Aid to Removing Valves.

AFTER removing a valve cotter it is often difficult to get the valve out of the guide. "` T.W.," of Heckmondwike, has found the following of great use He bored a hole in each valve head to take a few threads of a fin, tap: ito then took a piece of fin. rod about 7 ins. long, screwed one end to suit, and turned the other end over to form a handle. Now, when the cotter is out, all he has to do is to screw the rod in and lift the valve.

" T.W." also tells us that after giving the radiator a good clean out, one shOuld add a little fine graphite to the water every day for a week. This will coat all the inside of the water jackets and thus stop the rust.

A Good "Get Home" Tip.

A. CURIOUS accident happened to " P.B.B.," of Ely (whose full name we should like to know), which would have stopped most drivers. While on the road and away from any help he had the cap of his pump cheek valve blow out. Instead of giving up, he did what all wise drivers do under such circumstances: he sat and thought over the matter until he hit upon a plan which enabled him to improvise a temporary cap.

Having a piece of jointing with him, he placed this over the hole, then placed a coin on the top of the jointing, and by means of a screw-hammer brought sufficient pressure to bear on the improvised cap to retain the water. He tells us that he was able to run in this fashion until a new cap arrived.