HINTS ON MAINTENANCE.

Page 72

If you've noticed an error in this article please click here to report it so we can fix it.

Lubricating Driving Chains.

NEARLY all steam wagons are fitted with roller' chains for transmitting the power of the engine to the road wheels, but, strange to say, very few types embody any provision for efficiently lubricating these chains, it being left to the driver to smear them with oil or grease, when, actually, it would seem pre

ferable to provide some sort of oiling device which would save the driver from a messy and, consequently, often-neglected operation.

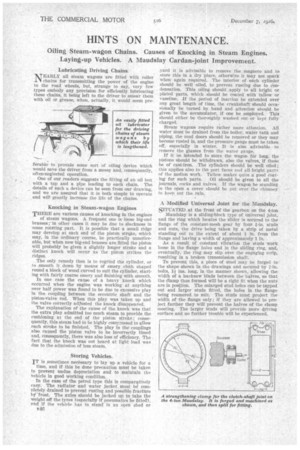

One of our readers suggests the fitting of an oil box with a tap and a pipe leading to each chain. The details of such a device can be seen from our drawing, and we are assured that it is both simple to operate and will greatly increase the life of the chains.

Knocking in Steam-wagon Engines THERE are various causes of knocking in the engines

of steam wagons. A frequent one is loose big-end brasses ;in other cases it may be due to slackness in some rotating part. It is possible that a small ridge may develop at each end of the piston stroke, which may, in the ordinary course, be practically unnoticeable, but when new big-end brasses are fitted the piston will probably be given a slightly longer stroke and a distinct knock will occur as the piston strikes the ridges.

The only remedy then is to regrind the cylinder, or to smooth it down by means of emery cloth shaped round a block of wood curved to suit the cylinder, starting with fairly coarse emery and finishing with smooth.

In one case the cause of a heavy knock which occurred when the engine was working at anything over half power was found to be due to excessive play in the coupling between the eccentric shaft and the piston-valve rod. When this play was taken up and the valve correctly adjusted the knock disappeared.

The explanation of the cause of the knock was that the extra play admitted too much steam to provide the cushioning at the end of the piston stroke; consequently, this steam had to be highly compressed to allow each stroke to be finished. The play in the couplings also caused the piston valve to be incorrectly timed and, consequently, there was also loss of efficiency. The fact that the knock was not heard at light load was due to the admission of less steam.

Storing Vehicles.

IT is sometimes necessary to lay up a vehicle for a time, and if this be done precaution must be taken to prevent undue depreciation and to maintain the vehicle in good working condition.

In the case of the petrol type this is comparatively easy. The radiator and water jacket must be completely drained to prevent rusting and possible fracture by frost. The axles should be jacked up to take the weight off the tyres (especially if pneumatics be fitted), and if the vehicle has to stand in an open shed or 1146 .yard it is advisable to remove the magneto and to store this in a dry place, otherwise it may not spark when again required. The interior of each cylinder should be well oiled, to prevent rusting due to condensation. This oiling should apply to all bright or plated parts, which should be coated with tallow or vaseline. If the period of inaction be extended over any great length of time, the crankshaft should occasionally be turned by hand and attention should be given to the accumulator, if One be employed. This should either be thoroughly washed out or kept fully charged.

Steam wagons require rather more attention. All water must be drained from the boiler, water tank and piping, the mud doors should he removed or they may become rusted in, and the pressure gauge must be taken off, especially in winter. It is also advisable to remove the glasses from the water gauge.

If it be intended to store the wagon for long, the pistons should be withdrawn, also the valves, if these be of cast-iron. The cylinders should be well oiled;• this applies also to the port faces and all bright parts of the motion work. Tallow makes quite a good coat ing for such parts. Oil should be given to all the journals, cocks and valves. If the wagon be standing in the open a cover should he put over the chimney to keep nut the rain.

A Modified Universal Joint for the Maudslay.

SITUATED at the front of the gearbox on the 4-ton Maudslay is a sliding-block type of universal joint, and the ring which locates the slider is secured to the flange of the constant-mesh gear by four a-in. studs and nuts, the drive being taken by a strip of metal standing out to the extent of about in. from the flange and having a width of approximately 1 in.

As a result of constant vibration the studs work loose in the flange holes and in the sliding ring, and, eventually, the ring may slip over I he engaging strip, resulting in a broken transmission shaft.

To prevent this, a piece of steel may be forged to the shape shown in the drawings and secured by a-in. bolts, 14 ins, long, in the manner shown, allowing the width of a hacksaw blade between the halves, so that the damp thus formed will be a tight fit when the nuts are in position. The enlarged stud holes can be tapped out and larger studs fitted, the holes in the flange being reamered to suit. The studs must project the width of the flange only ; if they are allowed to project farther they will prevent the halves of the clamp meeting. The larger Muds will provide more driving surface and no further trouble will be experienced.