How to Keep Your Lorry Fit.—XII.

Page 4

Page 5

If you've noticed an error in this article please click here to report it so we can fix it.

This Time We Deal Briefly with the Care of the Leyland Steam Chassis.

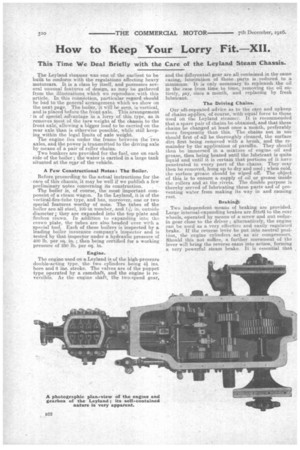

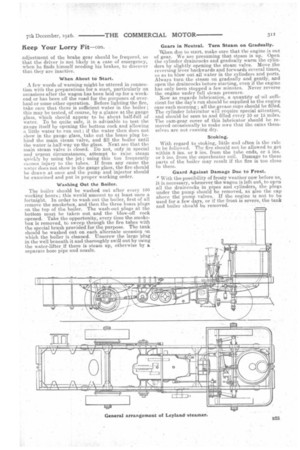

• The Leyland steamer was one of the earliest to be built to conform with the regulations affecting heavy motorcars. It is a class by itself, and possesses several unusual features of design, as may be gathered from the illustrations which we reproduce, with this article. In this commotion, particular regard should be had to the general arrangement which we show on the next page. The boiler, it will be seen, is vertical, and is placed before the front axle. This arrangement : is of special ad-vantage in a lorry of • this. type, as it removes most: of the tare weight of the chassis to the front axle; allowing a bigger load to becarried on the rear axle than is otherwise possible, while still keeping within the legal limits of axle weight.

The engine lies under the frame between the two axles, and the power is transmitted to the driving axle by means of a pair of roller chains.

Two bunkers are provided for the fuel, one on each side of the boiler ; the water is carried in a large tank situated at the rear of the vehicle.

A Few Constructional Notes: The Boiler.

Before proceeding to the actual instructions for the care of this chassis, it may be well if we publish a few preliminary notes concerning its construction. ,

The boiler is, of course, the most important component of a tteatn wagon. In the Leyland, it is of the vertical-fire-tube type, and has, moreover, one or two special features worthy of note. The tubes of the boiler are all steel, 1.05-in number, and 1-fe in. outside diameter; they are expanded into the top plate and firebox crown. In addition to expanding into the crown plate, the tubes are also beaded over with a special tool. Each of these boilers is inspectedby a leading boiler insurance company's inspector and is tested by that inspector under a hydraulic pressure of 400 lb. per sq. in. ; then being certified for a working pressure of 250 lb. per sq: in.

Engine.

The engine used on a Leyland is of the high-pressure double-acting type, the two cylinders being 4i. ins. bore and 6 ins. stroke. The valves are of the poppet type operated by a camshaft, and the engine is reversible. As the engine shaft, the two-speed gear,

and the differential gear are all contained in the same easing, lubrication of these parts is reduced to a minimum. It is only necessary to replenish the oil in the case from time to time, removing the oil entirely, ray, once a month, and replacing by fresh lubricant.

The Driving Chains.

Our oft-repeated advice as to the care and upkeep of chains applies, of course, with equal force to those used on the Leyland steamer. It is recommended that a spare pair of chains be obtained, and that these chains be changed at least once a month, preferably more frequently than this. The chains not in use should first of-all be thoroughly cleaned, the surface dirt first being removed with a brush, and the remainder by the application of paraffin. They should then be immersed in a mixture of engine oil and grease, then being heated until the lubricant is quite liquid and until it is certain that portions of it nave penetrated to every part of the chains. They may then be removed, hung up to dry and cool ; when cold, the surface grease should he wiped off. The object of this is to ensure a. supply of oil or grease inside the rollers and at the rivets. The double purpose is thereby served of lubricating these parts and of preventing water from making its way in and causing rust.

Brakinet Two independent means of braking are provided. Large internal-expanding brakes are fitted to the rear wheels, operated by means of a screw and nut reduein gear close to the driver ; alternatively, the engine can be used as a very effective and easily regulated brake. If the reverse lever be put into neutral position, the engine cylinders act as air compressors. Should this not suffice, a further movement of the lever will bring the reverse cams into action, forming a very powerful steam brake. It is essential that adjustment of the brake gear should be frequent. so that the driver is not likely in a ease of emergency, when he finds himself needing his brakes, to discover that they are inactive.

When About to Start.

A few words of warning might be uttered in connection with the preparations for a start, particularly on occasions after the wagon has been laid up for a weekend or has been .off the road: for the purposes of overhaul or some other operation. Before lighting the fire, take care that there is sufficient water in the boiler ; this may be tested, of course, by a glance at the gauge glass, which should appear to be abput half-full of water. To be quite safe, it is advisable to test the gauge itself by opening the bottom cock and allowing a little water to run out ; if the water then does not show in the gauge glass, take out the brass plug behind the main steam valve, and fill the boiler until the water is half-way up the glass. Next see that the main steam valve is closed. Do not, ody in special and urgent circumstances, attempt to raise steam quickly by using the jet ; using this too frequently ceases injury to the tubes. If from any cause the water does not show in the gauge glass, the fire should be drawn at once and the pump and injector should be examined and put in proper working order.

Washing Out the Boiler.

The boiler should be washet but after every 100 working hours.; this would amount to at least once a fortnight. In order to wash out the boiler, first of all remove the sinokebox, and then the three bvass plugs on the top of the boiler. The wash-out plugs at the bottom must be taken out and the blow-off cock opened. Take the opportunity, every time the smokebox is removed, to sweep through the fire tubes with the special brush provided for the purpose. The tank should be washed out on each alternate occasion on which the boiler is cleaned. Unscrew the large plug in the well beneath it and thoroughly swill out by using the water-lifter if there is steam up, otherwise by a separate hose pipe and nozzle. Gears in Neutral. Turn Steam on Gradually.

When due to start, make sure that the engine is out of gear. We are presuming that. steam is up. Open the cylinder draincocks and gradually warm the cylinders by slightly opening the steam valve. Move the reversing lever backwards and forwivds Several times, so as to blow out all water in the cylinders and ports. Always turn the steam on gradually and gently, and open the draincocks before starting, even if the engine has only been stopped a few minutes. Never reverse the engine under full steam pressure. Now as regards hibrication, a quantity of. oil sufficient for the day's run should be supplied to the engine case each morning; all the grease cups should be filled. The cylinder lubricator will require special attention, and should be seen to and filled every 10 or 15 miles. The cam-gear cover of this lubricator should be removed occasioeally.to make sire that the cams themselves are not running dry.

Stoking.

With regard to stoking, little and often is the rule to be followed. The fire should not be allowed to get within 8 ins. or 9 ins, from the tube ends, or 4 ins. or 5 ins, from the superheater coil. Damage to these parts of the boiler may result if the fire is too close to them.

Guard Against Damage Due to Frost.

With the possibility of frosty weather now before us, it is necessary, whenever the wagon is left outt.to open all the draincocks in pipes and cylinders, the plugs under the pump should be removed, as also the cap above the pump valves. If the engine is not to be used for a few days, or if the frost is severe, the tank and boiler should be removed.