One-piece Alloy Hoops for Economical Van-building

Page 76

If you've noticed an error in this article please click here to report it so we can fix it.

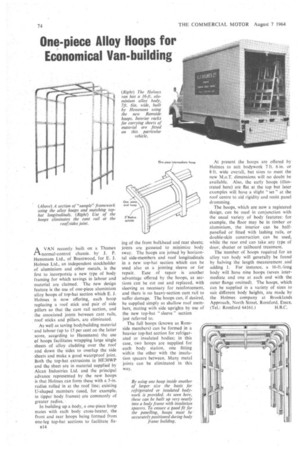

rtA VAN recently built on a Thames normal-control chassis. by J. P. Hensmans Ltd., of Brentwood, for E. J. Holmes Ltd., an independent stockholder of aluminium and other metals, is the first to incorporate a new type of body framing for which savings in labour and material are claimed. The new design feature is the use of one-piece aluminium alloy hoops of top-hat section which E. J. Holmes is now offering, each hoop replacing a roof stick and pair of side pillars so that the cant rail section, and the associated joints between cant rails, roof sticks and pillars, are eliminated.

As well as saving bodybuilding material and labour (up to 15 per cent on the latter score, accprding to Hensmans) the use of hoops facilitates wrapping large single sheets of alloy cladding over the roof and down the sides to overlap the side sheets and make a good waterproof joint. Both the top-hat extrusions in HE3OWP and the sheet are in material supplied by Alcan Industries Ltd. and the principal advance represented by the new hoops is that Holmes can form these with a 5-in. radius rolled in at the roof line; existing U-shaped members (used, for example, in tipper body frames) are commonly of greater radius.

In building up a body, a one-piece hoop mates with each body cross-bearer, the front and rear hoops being formed from one-leg top-hat sections to facilitate fix ing of the front bulkhead and rear sheets; joints are. gusseted to minimize body sway. The hoops are joined by horizontal side-members and roof longitudinals in a new top-hat section which can be used also as a jointing sleeve or for repair. Ease of repair is another advantage offered by the hoops, as sections can be cut out and replaced, with sleeving as necessary for reinforcement, and there is no heavy-section cant rail to suffer damage. The hoops can, if desired, be supplied simply as shallow roof members, mating with side uprights by use of the new top-hat " sleeve " section just referred to.

The full hoops (known as Romside members) can be formed in a heavier top-hat section for refrigerated or insulated bodies; in this case, two hoops are supplied for each body station, one fitting within the other with the insulation spacers between. Many metal joints can be eliminated in this way.

At present the hoops are offered by Holmes to suit bodywork 7 ft. 6 in. or 8 ft. wide overall, but sizes to meet the new M.o.T. dimensions will no doubt be available. Also, the early hoops (illustrated here) are flat at the top but later examples will have a slight " set " at the roof centre to aid rigidity and resist panel drumming.

The hoops, which are now a registered design, can be used in conjunction with the usual variety of body features: for example, the floor may be in timber or aluminium, the interior can be halfpanelled or fitted with lashing rails, or double-skin construction, can be used, while the rear end can take any type of door, shutter or tailboard treatment.

The number of hoops required for an alloy van body will generally be found by halving the length measurement and adding 1. For instance, a 16-ft.-long body will have nine hoops (seven intermediate and one at each end with the outer flange omitted). The hoops, which can be supplied in a variety of sizes to suit different body heights, are made by the Holmes company at Brooklands Approach, North Street, Romford, Essex.

(Tel.: Romford 64161.) H.B.C.