HINTS ON MAINTENANCE.

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

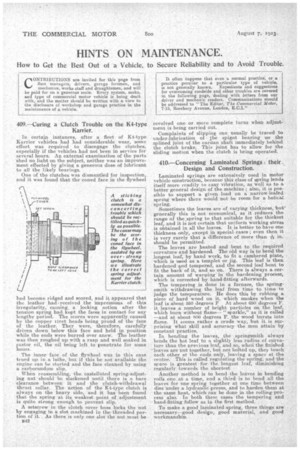

409.—Curing a Clutch Trouble on the .K4-type Karriet.

In certain instances, after a fleet of K4-type Karrier vehicles had ad considerable wear, some effort was required to disengage the .clutches, especially if the vehicles had not been in service for several hours. An external examination of the parts -shed no light on the subject, neither was an improvement effected, by giving a generous dose of lubricant to all the likely bearings.

One of the clutches was dismantled for inspection, and it was found that the coned face in the flywheel had become ridged and scored, and it appeared that the leather had :received the impressions of this irregularity; causing, a locking action after the tension spring had kept the faces in contact for any lengthy period. The scores were, apparently caused by the copper iiyet heads being proud of the face of the leather. They were, therefore, carefully driven down below this face and held in position while the ends were burred over anew. The leather was then roughed up with a rasp and well soaked in pastor oil, the oil being left to penetrate for some hours.

The inner face of the flywheel was in this case trued up in a lathe, but if this be not available the engine can be started and the face. cleaned by using carborundum slip.

When reassembling, the castellated spring-adjusting nut should' be slackened until there is a bare clearance between it and the clutch-withdrawal thrust collar. The action of the K4-type clutch is always on the heavy side, and it has been found that the spring Bt its weakest point of adjustment is quite strong enough to prevent slip.

A setscrew in the clutch cover boss locks the nut by engaging in a slot machined in the threaded portion of it. As there is only one slot the nut must be

B42 revolved one or more complete turns when adjustment is being carried out.

Complaints of slipping can usually be traced to under-lubrication of lhe spigot bearing on the .aplined joint of the cantan shaft immediately behind the clutch brake. This joint has to allow for the sliding motion when the clutch is being operated.

410,—Concerning Laminated Springs : their. ., Design and Construction.

Laminated springs are extensively used in motor vehicle construction, because this class of spring lends itself more readily to easy vibration, as well as to a better general design of the machine ; also, it is possible to support a given load on a narrow-leafed spring where there would not be room for a helical spring.

Sometimes the leaves are of varying thickness, but generally this is not economical, as it reduces the range of the spring to that suitable for the thickest leaf, and it is not certain that uniforin Working stress is obtained in all the leaves. It is better to have one thickness only, except in special. cases ; even then it is very rarely that a difference of more than in. should be permitted. The leaves are heated and bent to the required curvature and hardened. The old way is to bend the longest leaf, by hand work, to fit a cambered plate, which is used as a templet or jig. This leaf is then hardened and tempered, and the second leaf bent to

Et the back of it, and so on. There is always a certain amount of warping in the hardening process', which is corrected by hand-fitting afterwards.

The tempering is done in a furnace, the springsmith withdrawing the leaf from time to time to

judge the temperature. He does this by rubbing a

piece of hard wood on it, which smokes when the leaf is about 550 degrees F At about 650 degrees F. it leaves a number of bright particles on the leaf,

which burn without flame— "sparkle," as it is called —and at about 800 degrees F. the wood bursts into

game. It seems rather a crude way, but it is surprising what skill and accuracy the men attain by constant practice.

In bending the leaves, the springsmith always bonds the hot leaf to a slightly less radius of curva ture than the previous leaf, and so, wheri the finished leaves are put together, but not bolted up, they touch each other at the ends only, leaving a space at the centre. This is called 'regulating the spring, and the apace is greatest for the longest leaf, diminishing regularly towards the shortest Another method is to bend. the leaves in bending rolls one at a time, and a third is to bend all the

leaves for -one spring together at one time between dies under a hydraulic presss, and to harden them at the same heat, which can be "done in the rolling precess also. In both these cases the tempering and hand-fitting follow as in the first method.

To make a good laminated•spring, three things are necessary—good design, good material, and good workmanship.