GRASS IS GREENER IN BLETCHINGTON

Page 61

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

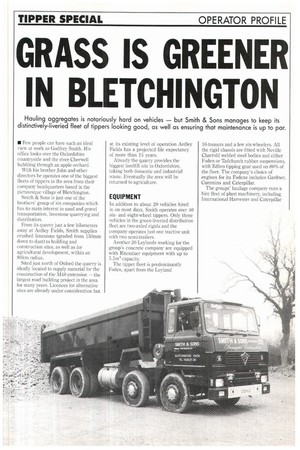

Hauling aggregates is notoriously hard on vehicles — but Smith & Sons manages to keep its distinctively-liveried fleet of tippers looking good, as well as ensuring that maintenance is up to par.

• Few people can have such an ideal view at work as Godfrey Smith. His office looks over the Oxfordshire countryside and the river Cherwell bubbling through an apple orchard.

With his brother John and other directors he operates one of the biggest fleets of tippers in the area from their company headquarters based in the picturesque village of Bletchington.

Smith & Sons is just one of the brothers' group of six companies which has its main interest in sand and gravel transportation, limestone quarrying and distribution.

From its quarry just a few kilometres away at Ardley Fields, Smith supplies crushed limestone (graded from 150mm down to dust) to building and construction sites, as well as for agricultural development, within an 80km radius.

Sited just north of Oxford the quarry is ideally located to supply material for the construction of the M40 extension — the largest road building project in the area for many years. Licences for alternative sites are already under consideration but at its existing level of operation Ardley Fields has a projected life expectancy of more than 15 years.

Already the quarry provides the biggest landfill site in Oxfordshire, taking both domestic and industrial waste. Eventually the area will be returned to agriculture.

EQUIPMENT

In addition to about 20 vehicles hired in on most days, Smith operates over 40 sixand eight-wheel tippers. Only three vehicles in the green-liveried distribution fleet are two-axled rigids and the company operates just one tractive unit with two semi-trailers.

Another 20 Leylands working for the group's concrete company are equipped with Ritemixer equipment with up to 5.5m3 capacity.

The tipper fleet is predominantly Foden, apart from the Leyland 16-tormers and a few six-wheelers. All the rigid chassis are fitted with Neville Charrold welded steel bodies and either Foden or Tadchurch rubber suspensions, with Edbro tipping gear used on 80% of the fleet. The company's choice of engines for its Fodens includes Gardner, Cummins and Caterpillar.

The groups' haulage company runs a hire fleet of plant machinery, including International Harvester and Caterpillar crawler and rubber-tyred loaders, as well as off-highway dump trucks and tracked hydraulic excavators. The big American Caterpillar truck engine is no stranger to the fleet workshop.

MAINTENANCE

The vehicles average around 64,000km a year and the company's replacement policy allows for up to eight years' operation, after which there is a queue of smaller operators waiting to pick them up privately. This says much for the condition in which the vehicles are maintained.

Godfrey likes "nothing better than to get among the spanners," but with a staff of 12 fitters maintaining both plant and road vehicles, he does not get the chance as often as he would like.

In an environment which is either very dusty, wet or gritty, he says: "We don't stint on oil or filters. Servicing is based on 8,000km intervals but never allowed to go longer than six weeks. We normally expect to change air filters, fuel filters and power assistance filters."

Except for the propshaft, manual greasing is no longer necessary because for the past four years every new vehicle in the fleet has been specified with Telehoist automatic lubrication, feeding up to 38 points on the vehicle and covering such items as slack adjusters, the body pivot and front springs. It works on a time basis and Godfrey considers grease to be cleaner then oil: 'You still get the occasional dropping but it doesn't spread like oil.

WORKSHOPS

Standards ot maintenance can often be indicated by the state of a workshop. Smith carries out major body repairs,

Godfrey Smith and his bmther John are main board directors of the family company which leas Ibunded in 1908. As well as servicing Smith's workshop carries out repairs to the vehicles' tipping bodywork.

including fitting replacement corner posts, top rails and pivots. Nonetheless the workshop floor and surrounds are immaculate. A new workshop is about to be commissioned for larger items of plant. It is equipped with an angled pit to minimise damage to the floor caused by turning tracked vehicles, electricallylowered exhaust and welding fume extractors, and a quiet, fast HPC Pulsar SK25 screw type air compressor.

A Ford Transit is fitted out as a mobile workshop and will soon be joined by another. Equipment includes welding gear, and 110V generator.

FUTURE

A three-axled Foden 6x4 tractive unit is on order. It is powered by a 261kW 3406B Cat engine, specified with a heavy-duty Spicer propshaft, for a dual function. It will haul both a low loader semi-trailer, for moving plant, and a 25.8m3 Wilcox Seadyke tipping trailer. Bodies used on the sixand eight-wheel rigids have capacities of 18m3 and 14m3, respectively.

ALTERNATIVES

While supporting Foden and Leyland the company does examine other alternatives. When approached recently by Iveco Ford to act as a proving agent for the 2421 Cargo powered by the latest Cummins C-series engine, Smith had no problem in fitting it into the group's operation: "Every little fault had to be recorded, but overall it has performed well," says Smith. Now it will consider buying one — but not yet. It will have to compete against the C-series-powered lightweight six-wheel Foden.

0 by Bill Brock.