A WEIGHTY MATTER

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

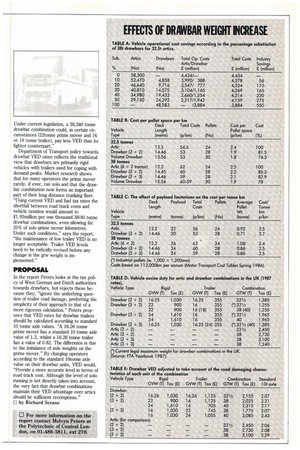

• Since maximum articulated vehicle weights were raised to 38 tonnes in May 1983, there has been a growing campaign for a similar increase for drawbar vehicles. Last November we carried a report on the first results of a study into the effects of a weight increase for drawbars. The report, by the Transport Division of the Environment Department at the Polytechnic of Central London, analyses the effects of a weight change on running costs, road wear and taxation.

RUNNING COSTS

Drawbar vehicles are cheaper to operate at any given weight than articulated vehicles, says the report. Though the purchase price of a drawbar combination can be between 25,000 and 210,000 greater than an equivalent articulated combination, it is cheaper to operate per kilometre. Savings come primarily from lower road tax, insurance premiums, wage rates, tyre wear and fuel consumption.

Drawbars also offer greater load volume. The report estimates the difference can be as much as 27% more volume in a drawbar than an articulated trailer, which can mean up to six more pallets. "A standard drawbar combination operating at 38 tonnes, reduces the cost per pallet mile by approximately 14-17% over a 38 tonne artic," says the report. "The use of specialist drawbars decreases the cost per pallet mile still further, ie by 22%."

Despite these advantages, the report predicts that 38 tonne drawbars would not replace existing 38 tonne artics "to any large extent" following an increase in maximum drawbar weights. This is because of the relatively high unladen weight of drawbars, with its consequent effect on payload potential. An increase to 38 tonnes for drawbars would raise maximum average pallet weights to 0.86 tonnes from 0.7 tonnes, but this is not enough to overcome drawbar payload disadvantages. "Typical articulated vehicles offer an additional two to three tonnes in payload over comparably weighted drawbar combinations," says the report. "As a result the cost per tonne mile is lower for articulated vehicles."

Research officer Melvyn Peters predicts that the main effects of the introduction of 38 tonne drawbars could be seen in the use of 321/2torine artics. "A wide scale substitution of artics at or below 321/2tonne by 38 tonne drawbars would significantly reduce the roadfreight industry's vehicle operating costs," he says. "For every 10% (5,830) of the 321/2tonne artic fleet replaced, savings of 256million could be realised." There would also be a reduction in the total population of 730 vehicles as the higher capacity drawbars replace the 321/2tonne artics.

The average road wear characteristics of drawbars have not been fully established, and Peters admits there is contradictory evidence. There are suggestions, for example, that drawbars can damage pavements more than artics of the same weight. By contrast, The Freight Transport Association claims that it should be relatively easy to achieve lower road wear characteristics with because the weight is spread more evenly along the vehicle's length.

"If average vehicle kilometres remain unchanged at 68,000km we know that a 10% substitution of 38/40 tonne drawbars will yield a road track cost saving of 25.47million," says the report. "However, at 80,000km per year, the track costs of replacement drawbars exceeds that of the 321/2tonne artics they have replaced by approximately .2250,000. Whereas if 38/40 tonne drawbar combinations follow the pattern set by 38 tonne artics, ie 85,000 vehicle tuns per year, with the same parameter values, then the road track costs for a 10% substitution will be 238.13 million, an increase of 25.25m over the 321/2tonne artics replaced."

Much of the eventual effect of drawbars on roadwear will depend on the proportion of solo running undertaken by the prime mover, predicts Peters. If the drawbar is used as a full unit on at least 75% of journeys then the savings in terms of road wear will be negligible. Also, the replacement of 321/2tonne artics by more capacious drawbars and the consequent drop in the number of trucks on the road will contribute to savings on road wear. However, the drawbars are likely to undertake longer journeys than the 321/2tonne artics they replace.

DRAWBAR TAXATION

The report suggests that drawbars "enjoy a significant vehicle excise duty advantage over similar weighted artics and this advantage would continue at 38/40 tonnes if the method of taxation is not amended. Under current legislation, a 38,340 tonne drawbar combination could, in certain circumstances (22tonne prime mover and 16 or 18 tonne trailer), pay less VED than its lighter counterpart."

Department of Transport policy towards drawbar VED rates reflects the traditional view that drawbars are primarily rigid vehicles with trailers used for coping with demand peaks. Market research shows that for many operators the prime mover rarely, if ever, ran solo and that the drawbar combination now forms an important part of their long distance trunking fleet. "Using current VED and fuel tax rates the shortfall between road track costs and vehicle taxation would amount to £1.93million per one thousand 38/40 tonne drawbar combinations, even allowing for 25% of solo prime mover kilometres. Under such conditions," says the report, "the maintenance of low trailer VED is no longer acceptable. Trailer VED levels need to be radically revised before any change in the gtw weight is implemented."

PROPOSAL

In the report Peters looks at the tax policy of West German and Dutch authorities towards drawbars, but rejects these because they, "ignore the underlying question of trailer road damage, preferring the simplicity of their approach to that of a more rigorous calculation." Peters proposes that VED rates for drawbar trailers should be calculated according to standard 10 tonne axle values. "A 16.26 tonne prime mover has a standard 10 tonne axle value of 1.2, whilst a 16.26 tonne trailer has a value of 0.82. The difference is due to the imbalance of axle weights on the prime mover." By charging operators according to the standard 10tomie axle value on their drawbar units, VED would, "Provide a more accurate level in terms of road track cost. Although the level of solo running is not directly taken into account, the very fact that drawbar combinations maintain their VED advantage over artics should be sufficient recompense."

D by Richard Scrase