The Metallurgist Aids the Solution of Engine Troubles

Page 31

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

Surface Amelioration of Steel by Ni/riding, Carburizing or "Compressing," Constitutes Outstanding Means for Lengthening Service Life and Preventing Premature Breakdown

IMPROVEMENT has been effected in cast-steel heels by the adoption of chill castings, containing approximately 1e75 per cenf nickel and 0.5 per cent. chromium. Theseare claimed tn,Ire superior in all respects to wheels of ernalluyed iron. Another interesting advance-is the formation, by a modified Atrament process, of a phosphate coating on piston rings. This is claimed to be advantageous during the running-in period, particularly when graphite is employed for lubricatioe. It is claimed that wear is much less than with piston rings not subjected to this treatment, whilst satisfactory sealing is obtained after a brief period.

Iron and steel may be given a black finish by first degreasing the parts, and then colouring them by plunging successively into two baths made up of a water solution of proprietary powders. The period of immersion ranges from 8-30 mins: ,in each bath; depending on the quality 61 finish desired.

Nitrided-steel crankshafts have been found to haVe. a much higher fatigue strength than crankshafts iii the Usual steels, the improvement being in the region of 25-60 per cent. This is claimed to be due mainly to the compressive stresses induced by the nitriding process.

Value of NaCNO In Case-hardening

Interesting studies have been made of the effects of case-hardening in snit baths. It appears to be established that case-hardening is not so effective with approximately 1 per cent. sodium ,cyanate in the bath as when about 5 per cent. is present-. Coarse-grained steels case-harden more rapidly than do the fine-grained varieties, Oxide films have been removed from ferrous metals by the application of heat in a vacuum: carbon must be present. Oxidized-iron test-pieces, containing small amounts of carbon, Were brightened in from 15-20 mills. at 800 degrees C., the removal of the filth of oxide being marked by a lowering of the carbon percentage. Stainless, steels had their oxide films eliminated When heated to approximately 1,050 degrees C. Oxidized iron of; high purity, with below. 0.001 per cent, carbon, could not be brightened, even when heated to 1,250 degrees G.

'A process for giving steel a blue, oxide film comprises heating in a bath composed of a mixture of equal parts of sodium and' potassium nitrate, with some manganese dioxide, to approxiMately 480 degrees C. Black surfaces may be produced by heating within the 540-650 degrees C. ran-ge and quenching in oil.

A temporary protection of steel surfaces, :during transport and storage, may be given by a new, liquid, black in colour, known as carbozite. This dries quickly to a hard gloss, which

resists acids, alkalis, .moisture, sea air, and temperatures up to about 205 degrees C. :The liquid is manufactured from a bituMinous mineral.

The Russians have been experimenting with a high-speed steel, free from tungsten, and containing 1.46 per cent. carbon, 11.7 per cent. chromium, 0.7 per cent. molybdenum, 0.3 per Cent, nickel, 0:2 per cent. vanadium: The heat-treatment temperatures were found to be Very critical and, for some types' of machininge it is claimed that this steel is equal t6 the'normal 18 per cent, tungsten high-speed steel, It is interesting to note that an Italian concern used a steel of similar composition for exhaust valves running direct on light-alloy seats.

Decarburization .of the three normal forms of molybdenum high-speed steel in use to-day, containing 4-0.5 pet' cent, molybdenum, is peeventable,. it is claimed, by'heat-treatment in salt baths in a special atmosphere containing 20 per cent. CO; or by coating the surfaces with borax or a special paint for open furnace work.'

New Stainless Steel Contains Silver A stainless steel, highly resistant to corrosion in the form of pitting, has been developed and contains approximately 16-20 per cent. chromium, 8-12 per cent, nickel, up to approximately 4 per cent. molybdenum, and up to about, 1 per cent, silver, the balance being iron.

A new American-patented highspeed. steel contains 1,0-1.6 per cent, carbon, 1-6 per cent. chromium, 1-5 per cent. molybdenum, 2-6 per cent. vanadium; and 1-4 per cent. tungsten, together with iron and normal

impurities. • Experiments have been carried out with molybdenum, cast-iron for brake drums, and it, appears that, as compared with plain and alloyed cast-irons of other types, 'this alloy is fess likely to crack when heated.

A new process for tool tipping comes from a•British -firm.. The tool shank is cut to the desired' length, and one face is ground in readiness for the tip. On to this prepared face is scattered a :1/32-in.' layer Of a Special powder and The high-speed steel tip is laid upon this coating. The assembly is then inserted in the furnace "pre-heating

chamber, and raised to a temperature of approximately 370 degrees C. The tool is then removed' to the hightemperattere chamber and heated until the powder has melted. The tip is then firmly pressed on to the shank, and plunged into oil for hardening. Thus, both brazing and hardening are achieved _simultaneously, and if necessary, the tool may be rehardened, after use, without removal of the tip. Thus, recessing of shanks may be dispensed with.

A' new welding process comprises the automatic application of a granular, slag-forming powder along the seam, in front' of the welding reel, which is a copper-plated continuous bate wire. The weld takes place below -this film of powder, which is partly melted, thus forming a flux blanket protecting the liquid metal-from oxidation by the atmosphere. Intense heat is generated below the powder layer; and this melts the welding rod 'and the steel plate edges so' that-. they fuse t4ether. Much higher current densities may he employed. The powder, when melted, is a good heat insulator and retains the welding heat within -a comparatively narrow area. Distortion is thus minimized whilst slow cooling of the weld metal is another good -feature.

Harder Grade _ of Stellite Available'

A new form of Stellite has been produced, being somewhat harder than the previous type, and has, therefore, a wider range of employment. It ti specially adapted to the machining o' high-tensile steels, such as thost employed in the manufacture o:

commercial vehicles. It obtainablE only as toolholder -bits, tipped tools, milling cutter blades, and special form tools,. either rectangular or circular.

A completely automatic, submerged burner, has been developed for heating pickling baths, the control equipment for which can be set to maintain the bath ternperalure within an extremely

-close range. .

A plant has been laid down for removing and recovering oil from swarf. The swarf is 'Washed by water sprays as it is transported by conVeror, and the oil is regained from the washing water by a,eonahination of settling and centrifuging. The plant will clean 10 tons of swarf a day, from which as much as 300 gallons of oil may, in all, be recovered.

Two heat-treatments have been found to give good results on casehardening steel, to Air Ministry Specification, 5.82. The quicker and better of elle two comprises heating the parts in an Open furnace to 840 degrees C., soaking for 60 mins., transferring the charge to a' second furnace at 650 degrees C., soaking for an identical period, followed by aircooling. This treatment is said to givi a finer grain structure and to improve both machinability and surface finish:

Some important tests have been carried out in the United States on the aarhurizing properties of 0.2 per cent. carbon alloy and plain carbon steels. Eight of the common case-hardening steels were tested in five different commercial solid case-hardening cantpounds. Chromium steels, when treated in four of the compounds, produced cases with very high carbon content on the surface. Only one of the compounds tested gave a low surface carbon concentration for chromium steels. Nickel opposed chromium in its effect on surfacecarbon concentration and 'lower carburizing temperatures did not produce cases of higher carbon-surface content. A low carbon skin (0.0003-0.001 in. deep) was obtainable after 10 hours or longer of casehardening, at 925 degrees C., but was not produced by lower case-hardening temperatures.

Low Phosphorus Steel for Castings

A new steel, particularly intended fol castings, has been produced aud is termed Armasteel. It is manufactured from a white iron containing 2.65. siser cent. carbon, 1.35 per cent'. silicon, 0,4 per cent. manganese, 0.13 per cent, sulphur, and 0.05 per cent. phosphorus. The castings are heated to approximately 954 degrees C., maintained at this temperature for about 15 hrs., cooled to 970 'degrees C., and then air cooled, or oil quenched. They have admirable machinability, high damping capacity, a high shock resistance at low temperastares, and respond well to flame hardening and local hardening, They also possess a high fatigue strength.

Two methods have been evolved for sealing up the pores in faulty castings by means of bakelite solutions. . In one, for small castings, the solution in forced in by external pressure. In the other, the casting is placed in a strong container from which the air can be evacuated. The solution is permitted to run in from a storage vessel until the castings are covered. Pressure is then exerted, so that the solution is squeezed into the body walls of the casting, filling the pores, .On removal, the casting is baked at about 160 degrees C. to cure the resin.

An easy way of tipping carbon-steel shanks with scrap high-speed steel is to clamp the tip in place on the shank and to tack weld at one spot. Top and sides of the tip are then heated by the oxy-acetylene torch burning an excess of acetylene. The torch head is held a little distance away at the outset, the tip being heated slowly to 760-925 degrees C., keeping the shank 150-205 degree8 C. cooler. Welding is then quickly done, using a, mediumcoated low-carbon electrode, with a lower amperage than normal. Before the welded-end of the tool has cooled, it is placed in a hardening furnace or forge fire, or is torch heated to 1,260 degrees C., and cooled in air. blast or oil quenched.

Surface compression is being investi, gated as a means for increasing the fatigue strength of springs. All valve springs, for example, are dealt with in this way in Germany. As a rule, a patented process is employed, comprising a shot blast of steel balls directed against the surface to be treated. When valve springs are made from ductile steel wire, which has to be hardened, it is advisable to surfacecompress the hardened steel wire before it is coiled. The treatment appears to give a much higher fatigue strength to the metal Welding Process With Many Uses A low-temperature welding process is being introduced, and is said to produce welds of the same colons as the basis metal in grey iron and semi-steel, whilst a good match can be ms de with cast steel and malleable iron. The welds retain • their colour, and are not porous. When' welding iron and steel castings, a paste, in conjunction with special rods, is used. The paste breaks up the graphite, reduces the sselding temperature, and ensures deep penetration of the liquefied rod into the parent metal. By this process scored cylinders, worn valve seatings, etc., can he reconditioned and built up for remachining, whilst holes which have been incorrectly drilled may also be filled up in the same way.

A new alloy, specially suitable for lining cylinder sleeves for internal combustion engines, contains 8-16 per cent. nickel, 3-6.5 per cent. copper, 0.5-10 per cent. chromium, 0.5-4.0 per cent. molybdenum (chromium 'and molybdenum together being not less than 4 per cent.), 0,25-2.0 per cent. manganese, 0.25-3.0 boron, 1-3 per cent. Carbon, 0.5-2.5 per cent. silicon, , sulphur not above 0:5 per cent., and, phosphorus the same. The balance is iron.

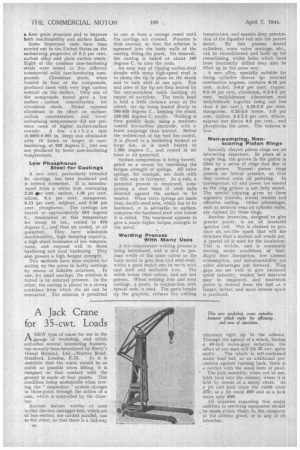

Non-pumping, Nonscoring Piston Rings Specially shaped piston rings are an interesting departure. In place -of a single ring, the groove in the piston is filled by a series of rings that flex in the groove. 'Normalpiston rings possess no lateral pressure, so that they cannot resist oil pumping. In consequence, oil and Power are wasted as the ring groove is not fully sealed. The special cupping given to these segments provides lateral tension and effective sealing. Other advantages, such as reduced wear on cylinder walls, are claimed for these rings.

Another invention, designed to give greater power, is an oil insulated ignition coil. This is claimed to• produce an . arc-like spark that will fire mixtures that a normal coil would not. A special oil is used for the insulation. This is mobile, and is constantly moving under conditions of heat. Rapid heat dissipation, low current consumption, and indestructibility. are other advantages put forward. Plug , gaps are set wide to give increased spark intensity, weaker, fuel mixtures may. be employed, and maximum power is derived from the fuel as a longer, hotter, and more intense spaik is produced.