MORE NEW MORRIS. COMMERCIALS

Page 48

Page 49

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

Six Models Equipped with Four-cylindered Power Units. Normal and Forward control Chassis for Pay-loads of 30-cwt., 2 tons and 3 tons. Exceptionally Low Prices and Comprehensive Specifications

WHEN a manufacturer of the importance of Morris Commercial Cars, Ltd., completely redesigns its range of medium-sized freight vehicles, it is obvious that the new products will be of outstanding interest to all classes of user. Small operators are just as keen as the owners of large fleets of vehicles to appreciate the finer points of up-to-date design and construction, whilst the knowledge that Ilie vast organization governed by Sir William Morris is being fully utilized in the production of the machines is, in itself, sufficient guarantee that, on a value-for-money basis, the various models offered are competitive in a world-wide sense.

A little more than a month ago we described a range of six-cylinder chassis we are now able to make the announcement that similar vehicles are available equipped with four-cylindered power units, in order to cater for those operators who have a decided preference for four-cylindered engines in commercial vehicles.

The new models are designated, 30 cwt., 2-tonners and a 3-tonner, the first and seoond being offered with alternative normal or forward-control cab arrangements. Except in the matter of minor details, the -chassis of both the sixcylinder and four-cylinder machines are identical, so that fleet owners could employ both types Of vehicle without complication arising in the spare-parts department As we have already indicated, prices are distinctly moderate considering the high-grade construction Nvhich characterizes the whole range. Before going into details, it might be mentioned that the 30-cwt. model is supplied as a chassis for 1198 (normal control) or 1206 (forward control), whilst the prices of lorries are £228 and 243 with the normal and forwardcontrol positions respectively.

There are two 2-ton models, varying in the wheelbase dimensions, the shorter type measuring 11 ft. 2 ins, between the axles, whilst the equivalent dimension for the long-wheelbase edition, available only with normal control, is 13 ft. 6 ins. This chassis costs 1221 and the lorry 1247.

c7P With normal control the chassis price of the short-wheelbase 2-tonner is £215 (as a tipping lorry £249), whilst with forward control the chassis is priced at 1221 and the complete lorry at £255. The 3-ton model is availablynly with forward control, £270 being... the price of the chassis and 1215 of the lorry. This vehicle has a wheelbase dimension similar to that of the 2-ton long-Wheelbase type Unquestionably, the most interesting feature of these models is the large body space permitted in the forward-control machines. Without cramping the cab or interfering with

engine accessibility to any marked extent, a clear platform of dimensions which should suit even the most exacting operator is provided. When it is realized that the 30-cwt. model has a platform area of 601 sq. ft., and the overall dimensions of the complete vehicle are bet 17 ft. 11 ins. and 6 ft. 1 in., the advantages offered will be more clearly understood. The 2-tonner has an even larger platform area (approximately 75 sq. ft.), whilst the platform of the 3-ton model measures 14 ft. by 6 ft. 6 ins. Naturally, the lengths of

ing the 3-tonner is worth noting, for it is claimed that it can operate at the maximum legal speed of 30 m.p.h., because the unladen weight does not exceed 2i tons, and the tax is therefore £28.

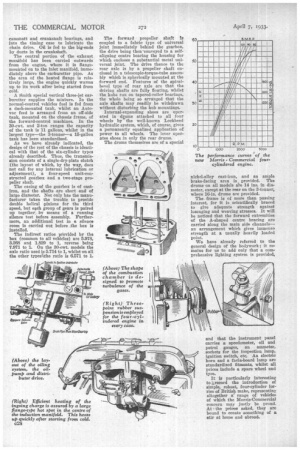

Turning now to a consideration of the power units, like the six-cylindered models, one design has been standardized throughout the range. A moderately large unit has been decided 'upon, the bore and stroke l of the cylinders being 100 mm. by 112 rum., which gives a capacity of about 3i litres ; rated at 24.8 h.p., the engine develops over 55 b.h.p. At 1,500 r.p.m. the torque is well over 1,600 lb.-ins., and, although, naturally the curve falls away somewhat after this maximum, there is no marked drop, as is evidenced by the fact that at 2,500 r.p.m. the torque figure remains at 1,400 lb.-ins.

The four cylinders a T e cast integrally

with the upper half of the crankcase, the walls of the latter component being continued downwards beyond the centre line of the crankshaft, in order to make the structure as stiff as possible and to give a perfectly flat sump flange. Internally, the crankcasecylinder-block casting is of robust construction, for substantial webs carry the main beatings and the whole structure is cross-braced to avoid weaving due to torque reaction.

Around each bore there is an ample water space, whilst at the side of the block is a detachable manifold designed so as to equalize the water flow throughout the block and head.

Following modern practice, the major part of each combustion chamber is located above the valves, the shape of the entrances into the cylinders being arranged to promote turbulence. The tappets are contained in two blocks, each of which is detachable—an arrangement that facilitates -replacement.

The three main bearings are 2i 'ins. iu diameter, whilst the corresponding dimension of the crankpins is 2 ins., the shaft being statically and dynamically balanced before assembly.

Particular interest attaches to the layout of the lubrication system, a notable feature being the absence of internal pipes in the supply line. The pump is of the gear type submerged in the sump. Oil is drawn by the pump through a detachable perforated-plate strainer, and fed into a large, renewable cartridge-type ipressure filter, whence it is delivered to the main duet running along the near side of the unit. From this channel it flows directly to the cam.shatt and crankshaft bearings, and into the timing case to lubricate the chain drive. Oil is fed to the big-ends by ducts in the crankshaft.

The central portion of the exhaust manifold has been carried outwards from the engine, where it is flangemounted on to the inlet manifold, immediately above the carburetter pipe. As the area of the heated flange is relatively large, the engine quickly warms up to its work after being started from cold.

A Smith special vertical three-jet carburetter supplies the mixture. In the normal-control vehicles fuel is fed from a dash-mounted tank, whilst an Autovac feed is arranged from an off-side tank, mounted on the chassis frame, of the forward-control machines. In the 30-cwt. and 2-ton ranges the capacity of the tank is 11 gallons, whilst in the largest type—the 3-tonner—a. 15-gallon tank has been standardized.

As we have already indicated, the design of the rest of the chassis is identical with that of the six-cylinder types already described. Thus, the transmission consists of a single-dry-plate clutch (the layout of which, by the way, does riot call for any internal lubrication or adjustment), a four-speed unit-constructed gearbox and a two-stage propeller shaft.

The casing of the gearbox is of castiron, and the shafts are short and of large diameter. Not only has the manufacturer taken the trouble to provide double helical pinions for the third speed, but each group of gears is paired up together, by means of a running silence test before assembly. Furthermore, an additional test in a silence room is carried out before the box is installed.

The indirect ratios provided by the box (common to all vehicles) are 5.978, 3.368 and 1.829 to 1, reverse being 7.971 to 1. On the 30-cwt. models the axle ratio used is 5.714 to 1, whilst on all the other typeeithe ratio is 6.571 to 1.

The forward propeller shaft Is coupled to a fabric type of universal joint immediately behind the gearbox, the drive being then.conveyed to a selfaligning centre bearing the housing for which encloses a substantial metal universal joint. The drive thence to the rear axle is by a propeller shaft enclosed in a telescopic-torque-tube assembly which is spherically mounted at the forward end. Features of the spiralbevel type of rear axle are that the driving shafts are fully floating, whilst the hubs run on tapered-roller bearings, the whole being so arranged that the axle shafts may readily be withdrawn without disturbing the hub mountings.

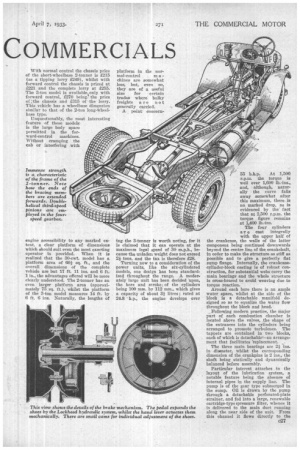

Internal-expanding shoes are operated in drums attached to all four wheels by the well-known Lockheed hydraulic system, which, of course, gives a permanently equalized application of power to all wheels. The lever operates shoes in only the rear drums.

The drums themselves are of a special nickel-alloy east-iron, and an ample brake-facing area is provided. The drums on all models are 14 ins, in diameter, except at the rear on the 3-tonner, where 16-in, drums are provided.

The frame is of more than passing interest, for it is scientifically braced to give adequate strength against lozenging and weaving stresses. It will be noticed that the forward extremities of the A-shaped centre bracing are carried along the main side channels— an arrangement which gives immense strength at a usually heavily loaded point.

We have already referred to the general design of the bodywork ; it remains for us to add only that a comprehensive lighting system is provided, and that the instrument panel carries a speedometer, oil and petrol gauges, an ammeter, sockets for the inspection lamp, ignition switch, etc. An electric horn and a facia-board lamp are standardized fitments, whilst all prices include a spare wheel and tyre.

It is particularly interesting to 4record the introduction of simple, robust, four-cylinder lorries of British make, representing altogether a range of vehicles of which the Morris-Commercial concern may justly be proud. At the prices asked, they are bound to create something of a stir at home and abroad.