Improved Benes Injection Pump

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

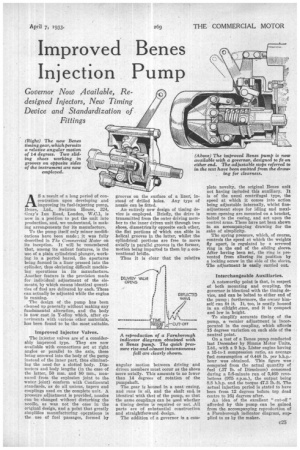

Governor Now 4vailable, Redesigned Injectors, New Timing Device and Standardization of Fittings

AS a result of a long period of concentration upon developing and improving its fuel-injecting pump, Benes, Ltd., Swinton House, 324, Gray's Inn Road, London, W.C.1, is now in a position to put the unit into production, and, we understand, is making arrangements for its manufacture.

To the pump itself only minor modifications have been made ; it was fully described in The Commercial Motor on its inception. It will be remembered that, among its salient features, is the use of a plain cylindrical plunger, working in a ported band, the apertures being formed in a liner pressed into the cylinder, thus obviating difficult machining operations in its manufacture. Another feature is the provision made for individual adjustment of the elements, by which means identical quantities of fuel are delivered by each. These can actually be adjusted while the engine is running.

The design of the pump has been cleaned up generally without making any fundamental alteration, and the body is now cast in V-alloy which, after experiments with various other materials, has been found to be the most suitable.

Improved Injector Valves.

The injector valves are of a considerably improved type. They are now available with connections set at right angles or parallel to the axis, these being screwed into the body of the pump instead of the inner part, thus eliminating the need for a slotted body. Diameters and body lengths (in the case of the latter, 50 nom. and 80 mm., measured from the explosion joint to the water joint) conform with Continental standards, as do all unions, tapers and couplings used on the complete unit. A pressure adjustment is provided, nozzles can be changed without disturbing the needle, as was not the case in the original design, and a point that greatly simplifies manufacturing operations is the use of fuel passages, formed by grooves on the surface of a liner, instead of drilled holes. Any type of nozzle can be fitted. • An entirely new design of timing device is employed. Briefly, the drive is transmitted from the outer driving member to the inner driven unit through two shoes, diametrically opposite each other, the fiat portions of which can slide in helical grooves in the latter, whilst the cylindrical portions are free to move axially in parallel grooves in the former, motion being imparted to them by a conventional bridle.

Thus it is clear that the relative

angular motion between driving and driven members must occur as the shoes move axially. This amounts to DO fewer than 14 degrees of rotation of the pumpshaft.

The gear is housed in a neat casing, and runs in oil, and the shaft end. is identical with that of the pump, so that the same couplings can be used whether a timing device is required or not. All parts are of substantial construction and straightforward design.

The addition of a governor is a com plete novelty, the original Benes unit not having included this auxiliary. It is of the usual centrifugal type, the speed at which it comes into action being adjustable internally, whilst fineadjustment stops for idling and maximum opening are mounted on a bracket, bolted to the casing, and act upon the control arms. These have not been shown in an accompanying drawing for the sake of simplicity.

The spring pressure, which, of course, controls the speed at which the weights fly apart, is regulated by a screwed ring in the end of the sliding sleeve. After having been set, the ring is prevented from altering its position by a locking screw in the side of the sleeve. The adjustment is easily carried out.

Interchangeable Auxiliaries.

A noteworthy point is that, in respect of both mounting and coupling, the governor is identical with the timing device, and can be bolted to either end of the pump ; furthermore, the owner himself can fit it. It, too, is neatly housed in an oiltight .case, and it is compact and low in height.

To simplify accurate timing of the pump, a vernier adjustment is incorporated in the coupling, which affords 15 degrees variation on each side of the neutral point.

On a test of a Benes pump conducted last December by Simms Motor Units, Ltd., with a 9 h.p. Lister engine having a 15-to-1 compression ratio, an average fuel consumption of 0.448 lb. per b.h.p.hour was obtained. This figure was computed from the actual quantity of fuel (.27 lb. of Diesoleum) consumed during a 5.6-minute run of 5,460 revolutions (975 -r.p.m.), the output being 8.8 b.h.p. and the torque 47.3 lb.-ft. The actual injection period is stated to have been from 12 degrees before top dead centre to 16* degrees after.

An idea of the excellent " cut-off " afforded by this pump can be gained from the accompanying reproduction of a •Farnborough indicator diagram, supplied to us by the maker.