• Despite the revolution that has swept through the British

Page 31

Page 32

Page 33

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

bus industry since deregulation in 1985, it seems that history is about to repeat itself.

In the early eighties the minibus was all the rage and hundreds of Ford Transits, Freight Rover Shcrpas and MercedesBenz 608s with 16-20 seats hit the roads to create an urban bus renaissance.

Since then routes have been consolidated and services rationalised. Customer demands and the need for efficient staff and vehicle utilisation have led many operators to look for slightly longer life and higher capacity minibuses. Companies like Optare and MCW responded with midibuses, at first with 25 and then 33 seats.

Then came the Dennis Dart; the midi with the engineering and passenger accessibility of the full-size bus. Not a truckderived compromise, but designed purely as a FSV. Available with 8.5, 9.0 or 9.8m chassis, the Dart can form the basis of a vehicle with seats for up to 43 passengers. Standing space pushes the capacity to 60 — just like the first mid-engined single-deckers of the 1950s.

Darts were originally offered as a onestop product with bodywork from Dennis's sister company Duple, but the sale of Du

ple to Plaxtons and the transfer of the Dart body rights to Carlyle Works has widened the options. Although the first 200 or so Darts in service are fitted with the Duple-designed Carlyle body, they are now available with the Wadham Stringer Portsdown body and a soon-to-belaunched new product from Plaxtons' Reeve Burgess subsidiary.

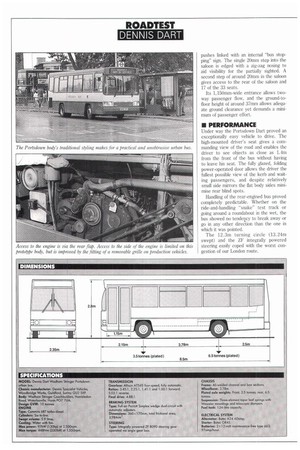

We have just taken the first Wadham Stringer Portsdown Dart over our arduous trans-London test route. Unlike the Carlyle option, the Portsdown body is conventional in its construction. Where the Carlyle body uses one-piece glued-in side panels, the Portsdown uses rivetted panels. Similarly, windows on the Portsdown are fitted by rubber gaskets and its styling is more traditional.

This, we found, did not work against the Wadham product, which matches the user friendliness of its main rival. It features a low entrance step; it is acceptably quiet inside; it is airy and draft free, with good visibility. The 33-seat 8.5m bus has been built to be as accessible and as attractive as possible to the elderly and disabled. Its saloon features well spaced vertical stanchions in conspicuous orange incorporating low-height palm-type bell pushes linked with an internal "bus stopping" sign. The single 20rrim step into the saloon is edged with a zig-zag nosing to aid visibility for the partially sighted. A second step of around 20mm in the saloon gives access to the rear of the saloon and 17 of the 33 seats.

Its 1,150mm-wide entrance allows twoway passenger flow, and the ground-tofloor height of around 37mm allows adequate ground clearance yet demands a minimum of passenger effort.

• PERFORMANCE

Under way the Portsdown Dart proved an exceptionally easy vehicle to drive. The high-mounted driver's seat gives a commanding view of the road and enables the driver to see objects as close as 1.4m from the front of the bus without having to leave his seat. The fully glazed, folding power-operated door allows the driver the fullest possible view of the kerb and waiting passengers, and despite relatively small side mirrors the flat body sides minimise rear blind spots.

Handling of the rear-engined bus proved completely predictable. Whether on the ride-and-handling "snake" test track or going around a roundabout in the wet, the bus showed no tendency to break away or go in any other direction than the one in which it was pointed.

The 12.3m turning circle (13.24m swept) and the ZF integrally powered steering easily coped with the worst congestion of our London route.

• DRIVER COMFORT The Dart is a difficult bus to crin iSt' from the driver's point of view. The instruments and controls, although simple and just adequate, are all well placed in the line of vision. The service brake and the Morse accelerator pedal are angled for driver comfort. The gear selector lever for the Allison automatic transmission and the air valve type parking brake are correctly placed. A multi-function stalk type control takes care of the horn, indicators, headlamp dip/flash and windscreen wash/ wipe. Operated by the left hand, this control was well placed on the test vehicle but had worn slightly loose and had to be treated with care.

The instrumentation consists only of a speedometer and air pressure gauges; warning lights are fitted for battery charging, oil pressure, low air pressure, the handbrake, low coolant level and high coolant temperature, turn signals, rear fog lights and headlight main beans.

"fhree banks of switches operate the interior and exterior lights and the saloon heater motors: slide controls direct air to the heating and demisting systems.

The full-air braking system brings the bus to a halt quickly and smoothly. Some squeaking was noticeable during light braking and this could prove a problem when operating at night in residential areas. During full-pressure simulated emergency stopping the rear wheels on the unladen vehicle did lock up, but the bus never deviated from a straight line. Some brake grab was felt through the steering during heavy braking but this did not impair control of the bus in any way.

Unlike its truck-based rivals the Dart is available only with fully automatic transmission. It uses the well-proven Allison AT545 box close-coupled to a turbocharged Cummins 6BT six-cylinder diesel with a rear-mounted offset radiator incorporating a thermostatically controlled magnetic-fan dutch assembly.

The ratios used give gear changes at 22, 36 and 58krn/h (14, 22 and 36mph): top speed is governed at 76km/h (47mph). A slight clunk is noticeable during the actual gear changes, but it is not serious enough to adversely affect the generally smooth ride.

• PASSENGER COMFORT Passenger ride on the Dennis bus is good despite the fact that holding down the chassis price and vehicle weight down precludes the fitting of air suspension.

With its three-element taper leaf springs and telescopic dampers the ride is soft enough for comfort and comparable to that provided by air on all but the worst road surfaces.

Body roll is minimal even during relatively harsh cornering, which is all the more important in a vehicle designed to carry more than a third of its passengers standing.

• BODYWORK

Like most modern purpose-built PSVs the Dennis Dart chassis is designed to be fully integrated with the body structure. It consists of an all-welded construction of channel and box sections with the body floor fitted directly to the chassis.

The rear engine, transmission and driveline are mounted in line to the rear of the conventional Eaton single-reduction hypoid rear axle. Chassis and body electries are fully integrated; the batteries are located to the front nearside of the frame.

The Wadham Stringer body is framed throughout of 25mm square hollow-section steel welded together to form a multiple ring structure. Full-length truss panels are welded to the inside of the main body structure, which is treated to prevent corrosion and electrolytic reaction between dissimilar metals.

The roof and body sides are all in aluminium sheeting rivetted to the main structural framing, with glass fibre moulding used for the front and rear body sections. A full-length rubber rail covers the joint between the upper and lower exterior body panels.

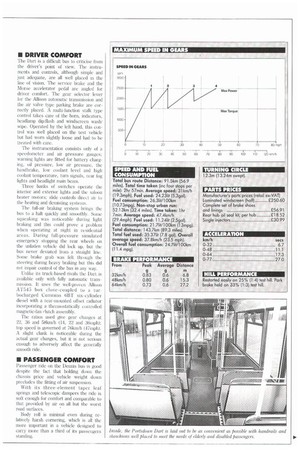

On our test vehicle access to the engine is through a flap at the rear of the body. A grille panel is rivetted in place at the rear off-side on production models this panel will be bolted in place to allow easier access to the side of the engine.

Daily engine oil checks are made by lifting the rear access panel. The water filler is fitted on the rear off-side corner; access is via a flap secured with a screwtype fastener.

Access to the vehicle electrics is via another flap, again secured by screw-type fastners, at the front of the saloon.

Glass fibre insulation is used in the cavities between the exterior and interior body panels, and extra sound deadening material is fitted above the engine compartment. On the test vehicle the interior below waist level is lined with carpet and the 33 seats are moquette covered. On production buses other materials will be offered to meet any special requirements.

One advantage that the Portsdown body has over its rival is that it comes with a good-sized destination display as standard. On our test vehicle the electronic digital display is programmed by a microchip and controlled by a combination device in the driver's cab. At the time of our test it was programmed with destinations served by various operators in Portsmouth and South Wales where the bus had previously been demonstrated.

We felt that the "sorry, not in service" message was most appropriate for a CM test. Despite this numerous would-be bus passengers waiting at bus stops on the route attempted to hail the Dennis throughout our mixed London route.

On our test route the 8.5-metre length and 2.35-metre width of the Dennis seemed the optimum size for the variety of road conditions. The route starts at the Heston service area on the M4, and although the midi is not designed for motorway operation the brief stretch of this type of running in fairly windy conditions did demonstrate that it is not adversely affected by cross winds.

On urban roads, whether in the city centre, or on the suburban housing estates towards the end of the route, the combination of size and turning circle allowed for easy negotiation of corners and on to and off bus-stop bays obstructed by the usual selection of badly and often illegally parked vehicles.

Fitted with its Wadham Stringer body the Dennis Dart as tested weighs 5.7 tonnes. It has a maximum gross vehicle weight of 10 tonnes; its rear axle capacity is eight tonnes and its front axle capacity is 4.3 tonnes. It is certified to carry 33 seated passengers and 14 standing so overloading is never a problem.

• SUMMARY

Moving with the traffic flow is a much more important feature for an urban bus than maximum or cruising speeds. Here the Dennis scored, taking a mere 11.14 seconds to reach our national built-up area speed limit. On the short stretches of Aroad the bus took a further 17 seconds to accelerate from 48km/h (30mph) to its top speed of just under 80km/h (50mph).

Overall the Dennis Dart Portsdown combination undoubtedly has all the ingredients for attractive public transport. It looks attractive, is easy to drive and is nippy; its fuel consumption is reasonable, it's easy and quick for passengers to get in and out of and it can accommodate enough of them to create a healthy amount of revenue.

It is a relatively new design, but is simply laid out and uses proven components to provide reliability.

Priced at around £55,000, the Portsdown Dart is more expensive than its front-engined rivals, but it has the life expectancy of a full-sized bus and should prove good value for money for operators confident enough.to plan for years ahead.

by Noel Millier