( From the Orekiinq Boer by Graham Montgomem

Page 84

Page 85

If you've noticed an error in this article please click here to report it so we can fix it.

DIAGNOSTIC is a term which has been misinterpreted by the CV industry in recent years, as it has tended to become associated with the dreaded computer.

Now, far be it for me to decry the computer, but the fact remains that as far as analysing faults in an engine go, then it can often be done quicker and cheaper by applying a little commonsense rather than resorting to complicated and expensive on-board circuitry.

As far as Seddon Atkinson is concerned, this commonsence is given some assistance by a couple of boxes — one containing a battery of pressure gauges and the other an electronic strobe/rev counter.

The eyes have it

The Seddon Atkinson faultfinding method owes more than a little to the system used by parent company International Harvester for fault diagnosis on the DT-466 and V-800 engines and presented in the form of a chart-cum-checklist.

According to Seddon Atkinson's service training manager, John Baxter -you can go a long way with the chart before you need any equipment at all''.

The first four tests merely involve someone using their eyes, checking for fuel leaks, and so on. John Baxter is keen on getting as much information as possible before any actual rand often unnecessary) work is done on the engine.

He delights in telling the story of art engine which was running badly due to a -fault in the fuel system-. The operator in question had replaced the nozzles and fuel filters and had even got round to switching pumps before the vehicle was sent round to Seddon Atkinson.

Point number one on the checklist is to see if there is enough clean fuel in the tank and a quick nose round revealed a plastic bag floating round inside. As far as this operator was concerned it was an expensive way of proving a point.

The correct operation of the throttle linkage is for it to override the governor at full throttle

when stationary and contact the high idle stop — or rather the "hi-idlestop in 1H vocabulary! If the linkage doesn't fulfil these requirements, then it will not operate the excess fuel device and cold-starting problems will arise.

Seddon has had cases of the 466 engine in the 300 being set at too low an idle speed The correct figure is 625rpm but, as John Baxter put it, -it sounds high at this speed-.. As the 466 engine can be made to tick over just like a Gardener, it is important to set this idle speed correctly using the electronic master tachometer as the one in the cab is not accurate enough at the bottom end. The same instrument is used to check the no-load high idle with the engine being at normal operating temperature for both these checks.

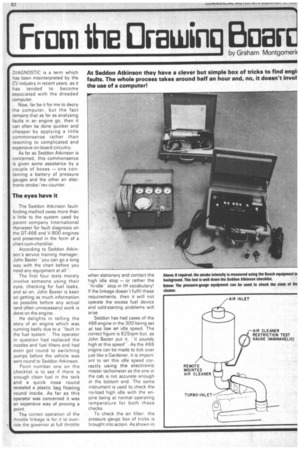

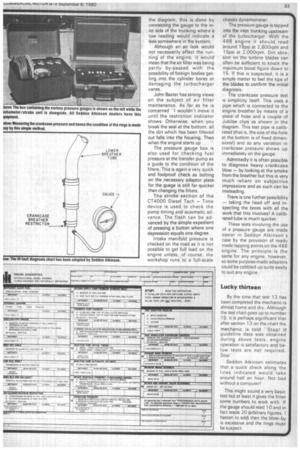

To check the air filter, the pressure gauge box of tricks is brought into action. As shown in the diagram, this is done by connecting the gauge to the inlet side of the trunking where a low reading would indicate a leak somewhere in the system.

Although an air leak would not necessarily affect the running of the engine, it would mean that the air filter was being partly by-passed with the possibility of foreign bodies getting into the cylinder bores or damaging the turbocharger vanes.

John Baxter has strong views on the subject of air filter maintenance. As far as he is concerned "I wouldn't move it until the restriction indicator shows. Otherwise, when you break the seal at the bottom, all the dirt which has been filtered out falls into the housing. Then when the engine starts up ..

The pressure gauge box is also used for checking fuel pressure at the transfer pump as a guide to the condition of the filters. This is again a very quick and foolproof check as bolting on the necessary adaptor plate for the guage is still far quicker than changing the filters.

The strobe section of the CT4000 Diesel Tach — Time device is used to check the pump timing and automatic advance. The flash can be advanced by the simple expedient of pressing a button where one depression equals one degree.

Intake manifold pressure is checked on the road as it is not possible to get full load on the engine unless, of course, the workshop runs to a full-scale chassis dynamometer.

The pressure gauge is tapped into the inlet trunking upstream of the turbocharger. With the 466 engine it should read around 19psi at 2,600rpm and 15psi at 2,000rpm. Dirt abrasion on the turbine blades can often be sufficient to knock the maximum boost figure down to 15. If this is suspected, it is a simple matter to feel the tips of the blades to confirm the initial diagnosis.

The crankcase pressure test is simplicity itself. This uses a pipe which is connected to the engine breather by means of a piece of hose and a couple of Jubilee clips as shown in the diagram. This test pipe is calibrated (that is, the size of the hole at the bottom is of fixed dimensions!) and so any variation in crankcase pressure shows up immediately on the gauge.

Admittedly it is often possible to diagnose heavy crankcase blow — by looking at the smoke from the breather but this is very much reliant on subjective impressions and as such can be misleading.

There is one further possibility — taking the head off and inspecting the bores with all the work that this involves! A calibrated tube is much quicker.

These tests involving the use of a pressure gauge are made easier in Seddon Atkinson's case by the provision of ready made tapping points on the 466 engine. The principle is the same for any engine, however, so some purpose-made adaptors could be cobbled up quite easily to suit any engine.

Lucky thirteen

By the time that test 13 has been completed the mechanic is almost home and dry. Although the test chart goes up to number 18, it is perhaps significant that after section 13 on the chart the mechanic is told "'Stop! If guideline data was obtained during above tests, engine operation is satisfactory and below tests are not required. Stop"

Seddon Atkinson estimates that a quick check along the lines indicated would take around half an hour. Not bad without a computer!

This might sound a very basic test but at least it gives the fitter some numbers to work with. If the gauge should read. 10 and in fact reads 20 (arbitrary figures, I hasten to add) then the blow-by is excessive and the rings must be suspect.