Quiet package for Bristol's VRT/3

Page 60

Page 61

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

A MARK 3 version of Bristol's VRT double-deck bus chassis announced today will provide the major psv chassis interest at the Earls Court show in a fortnight's time. As well as engine encapsulation to reduce exterior noise levels to below 80dBA, a whole host of detail modifications to the chassis have been introduced. From now on the Leyland 510 engine in 127 kW (170 bhp) form is offered as a regular option to the Gardner 6LX and 61.XB units.

The standard specification of the VRT! 3, which will go into full production from next March, will include Leyland's close-ratio, fully-automatic G2 gearbox. Of 241 VRT/ 3s planned for production between March and September next year, 84 will have the Leyland engine. The majority of those will go to National Bus but their's will all be fitted with the conventional semiautomatic gearbox. Only 19 of the total built for Reading Corporation, will be tilted with the G2.

The major changes in the VRT/ 3's specification have been necessary to encapsulate the engine. This is an exercise which is becoming increasingly common these days as manufacturers try to meet stricter noise controls. However, Cyril Eyles, Bristol's chief engineer, had a rather more straightforward task than some of his competitors. The main problem created by encapsulation, of course, is the dissipation of the additional heat which is built up. The VRT is the only UK rearengined double-deck bus design which has its radiator at the front.

Suck and blow

To ensure an adequate air flow across the engine a large 559m (2 in) diameter eight-blade fan is mounted on the offside of the engine. This is driven from the engine by a short coupling shaft and a poly V-belt. The fan is overhung to avoid the usual problem of radial supporting struts which both impede the airflow and conduct noise and vibration. The fan itself is mounted in a grp moulding which connects with ducting inside the bodywork. Close cooperation between Bristol and Eastern Coach Works has resulted in a particularly impressive airflow pattern.

Air is sucked in through an inlet in the rearmost panel on the offside of the upper deck, a site chosen because air is forced against the side of the vehicle at that point during forward movement. After being blown across the engine by the fan the air is extracted by similar trunking on the vehicle nearside to an outlet grille on the rear corner of the upper saloon. At speed there is a natural tendency for a vacuum to form at that point, so air is literally dragged from the vent.

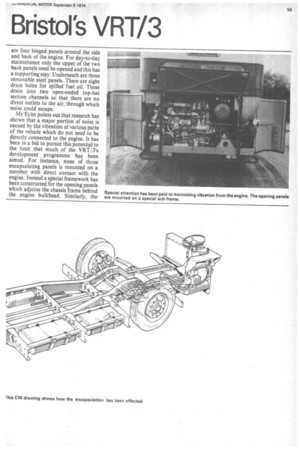

The quietened Bristol is unusual among vehicles with encapsulated engin-es in that the panels used for the purpose are not specially insulated. Instead they are formed of fairly thick grp but rely for their noise-deadening properties on their good sealing. There are four hinged panels around the side and back of the engine. For day-to-day maintenance only the upper of the two back panels need be opened and this has a supporting stay. Underneath are three removable steel panels. There are eight drain holes for spilled fuel oil, These drain into two open-ended top-hat section channels so that there are no direct outlets to the air, through which noise could escape, Mr Eyles points out that research has shown that a major portion of noise is caused by the vibration of various parts of the vehicle which do not need to be directly connected to the engine. It has been in a bid to pursue this potential to the limit that much of the VRT/ 3's development programme has been aimed. For instance, none of those encapsulating panels is mounted on a member with direct contact with the engine. Instead a special framework has been constructed for the opening panels which adjoins the chassis frame behind the engine bulkhead. Similarly, the are mounted on a special sub-frame. underpanels have two special subframes to support them.

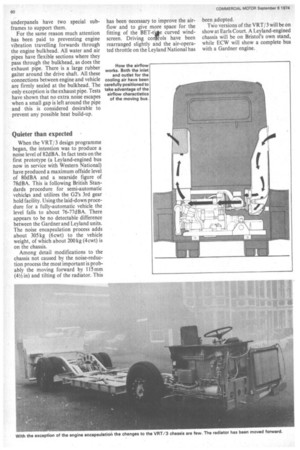

For the same reason much attention has been paid to preventing engine vibration travelling forwards through the engine bulkhead. All water and air pipes have flexible sections where they pass through the bulkhead, as does the exhaust pipe. There is a large rubber gaiter around the drive shaft. All these connections between engine and vehicle are firmly sealed at the bulkhead. The only exception is the exhaust pipe. Tests have shown that no extra noise escapes when a small gap is left around the pipe and this is considered desirable to prevent any possible heat build-up.

Quieter than expected When the VRT/ 3 design programme began, the intention was to produce a noise level of 82dBA. In fact tests on the first prototype (a Leyland-engined bus now in service with Western National) have produced a maximum offside level of 80dBA and a nearside figure of 78dBA. This is following British Standards procedure for semi-automatic vehicles and utilizes the G2's 3rd gear hold facility. Using the laid-down procedure for a fully-automatic vehicle the level falls to about 76-77dBA. There appears to be no detectable difference between the Gardner and Leyland units. The noise encapsulation process adds about 305 kg (6 cwt) to the vehicle weight, of which about 200 kg (4 cwt) is on the chassis.

Among detail modifications to the chassis not caused by the noise-reduction process the most important is probably the moving forward by 115 mm (41/2 in) and tilting of the radiator. This has been necessary to improve the airflow and to give more space for the fitting of the BET-t' e curved windscreen. Driving coWols have been rearranged slightly and the air-operated throttle on the Leyland National has been adopted.

Two versions of the VRT/ 3 will be on show at Earls Court. A Leyland-engined chassis will be on Bristol's own stand, while ECW will show a complete bus with a Gardner engine.