AEC's V8 Sabre for high-speed touring

Page 68

Page 69

If you've noticed an error in this article please click here to report it so we can fix it.

by A. J. P. Wilding, MIMechE, MIRTE

A COMPLETELY NEW passenger chassis is to be introduced by AEC Ltd. at the Commercial Motor Show. Called the Sabre, one of its principal uses is likely to be long-distance high-speed touring. The AEC BOO Series V8 is used—mounted longitudinally at the rear end—and the specification provides for speeds up to 75 mph with 12m-long, 53-seat bodies.

The Sabre has the V8 diesel with the full rating of 247 bhp gross (BS AU 141) at 2,600 rpm and this drives forward to the rear axle through a five-speed semi-automatic gearbox.

Compact installation

The engine and gearbox assembly makes a compact installation at the rear end of the chassis and electrical components are grouped in a weatherproof compartment on the side of the chassis close to the engine. The radiator is mounted on the right-hand side of the chassis at the rear end and the fan drive is through a right-angle transmission unit. On the Sabre to be featured at the Earls Court Show this drive will incorporate a small air-operated clutch. The equipment is made by Dynair Ltd. of Stroud, Gloucestershire, and the clutch is controlled through a temperature sensing unit fitted in one of the water hoses. Before a set temperature is reached the air pressure valve feeding the clutch is closed so that the drive is disengaged. But a further increase in cool ant temperature opens the air circuits and pressure is fed to the clutch to engage the drive to the fan.

Wheelbase of the Sabre is 2011 (6.096m) with the overall chassis length 3811 2in. (11.63m). Overall width is 8ft (2.44m) and the estimated kerb weight of the chassis is 5 ton 1.25cvvt.

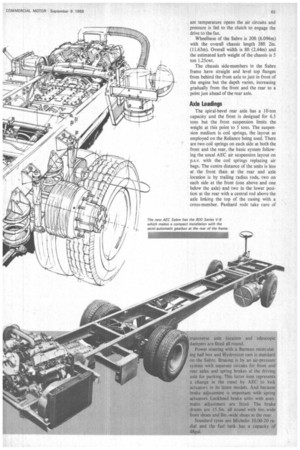

The chassis side-members in the Sabre frame have straight and level top flanges 'from behind the front axle to just in front of the engine but the depth varies, increasing gradually from the front and the rear to a point just ahead of the rear axle.

Axle bangs

The spiral-bevel rear axle has a 10-ton capacity and the front is designed for 6.5 tons but the front suspension limits the weight at this point to 5 tons. The suspension medium is coil springs, the layout as employed on the Reliance being used. There are two coil springs on each side at both the front and the rear, the basic system following the usual AEC air suspension layout on p.s.v. with the coil springs replacing air bags. The centre distance of the units is less at the front than at the rear and axle location is by trailing radius rods, two on each side at the front (one above and one below the axle) and two in the lower position at the rear with a central rod above the axle linking the top of the casing with a cross-member. Panhard rods take care of transverse axle location and telescopic dampers are fitted all round.

Power steering with a Burman recirculat tug ball box and flydrostcer ram is standard on the Sabre. Braking is by an air pressure system with separate circuits for front and rear axles and spring brakes at the driving axle for parking. This latter item represents a change in the trend by AE(' to lock actuators in its latest models. And because brake adjustment is important with spring actuators Lockheed brake units with auto matic adjustatent are fitted, The brake drums are I5.5in. all round with 6in.-wide front shoes and 8in.-wide shoes at the rear.

Standard tyres are Michelin 10.00-20 radial and the fuel tank has a capacity of 4Rgal.