Ford fits Perkins V8 in D1000 range

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

by Tony Wilding

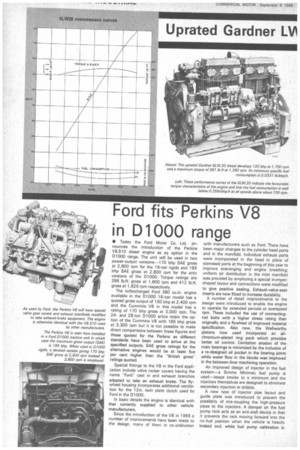

• Today the Ford Motor Co. Ltd. announces the introduction of the Perkins V8.510 diesel engine as ar) option in the 01000 range. The unit will be used in two power-output versions--170 bhp SAE gross at 2,600 rpm for the 16-ton rigids and 185 bhp SAE gross at 2,800 rpm for the artic versions of the 01000. Torque ratings are 396 lb.ft. gross at 1,600 rpm and 412 b.ft. gross at 1,625 rpm respectively.

The turbocharged Ford 360 cu.in. engine available in the 01000 16-ton model has a quoted gross output of 150 bhp at 2,400 rpm and the Cummins V8 in this model has a rating of 170 bhp gross at 3,000 rpm. The 24and 28-ton 01000 artics retain the option of the Cummins V8 with 185 bhp gross at 3,300 rpm but it is not possible to make direct comparisons between these figures and those quoted for the Perkins as different standards have been used to arrive at the specified outputs. SAE gross ratings for the alternative engines would be at least five per cent higher than the "British gross" ratings quoted.

Special fittings to the V8 in the Ford application include valve rocker covers having the name "Ford" cast in and exhaust branches adapted to take an exhaust brake. The flywheel housing incorporates additional ventilation for the 12in. twin plate clutch used by Ford in the D1000.

In basic details the engine is identical with that currently supplied to other vehicle manufacturers.

Since the introduction of the V8 in 1965 a number of improvements have been made to the design, many of them in co-ordination with manufacturers such as Ford. There have been major changes to the cylinder head ports and in the manifold. Individual exhaust ports were incorporated in the head in place of siamesed ports at the beginning of this year to improve scavenging and engine breathing; uniform air distribution in the inlet manifold was provided by employing a special trumpetshaped layout and connections were modified to give positive sealing. Exhaust-valve-seat inserts are now fitted to increase durability.

A number of detail improvements to the design were introduced to enable the engine to operate for extended periods at overspeed rpm. These included the use of connectingrod bolts with a higher stress rating than originally and a flywheel of improved material specification. Also new, the Wellworthy pistons now used incorporate an allchromium-plated ring pack which provides better oil control. Cavitation erosion of the main bearings is minimized by the inclusion of a re-designed oil pocket in the bearing joints while water flow in the blocks was improved in the between-liner machining operation.

An improved design of injector in the fuel system—a Simms Minimec fuel pump is used—keeps smoke to a minimum and the injectors themselves are designed to eliminate secondary injection or dribble.

A new type of injector pipe layout and guide plate was introduced to prevent the possiblity of mis-coupling the high-pressure pipes to the injectors. A damper on the fuel pump rack acts as an anti-stall device in that it prevents the rack moving forward into the no-fuel position when the vehicle is heavily braked and, while fuel pump calibration is

said to ensure good starting at temperatures down to minus 20deg F, Ford will offer coldstart equipment as an option.

Auxiliaries fitted for the Ford application include a gear-driven SC12 air compressor which has a capacity of 12 cu.ft.lmin at 1,200 rpm, a CAV AC5 alternator and CAV SL5 starter. The water pump is of the centrifugal type and is belt driven.

The VS engine for Ford will be built on the new production line at the fully automated factory that Perkins has recently opened in Peterborough. But an important aspect of the Ford use is that the Ford Motor Co. will be responsible for the guarantee, parts supply and servicing of the engines it uses.