COMMER'S LATEST ACHII

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

VEVIENT-a 30 m.p.h. 5-tonner Full and Exclusive -Details of Two Entirely New Commer

Chassis Expressly Built to Carry, with Economy and Safety, 4-5-ton Pay-loads

'k TOT so long ago, the suggestion that four-wheeled vehicles could be built to carry, with safety and

efficiency, pay-loads up to 5 tons on an unladen weight of under 24 tons would have been met with some thinglike incredulity, but we have for some time held the opinion that this would eventually be achieved. It is meet that the pioneer in this connection should be one of the earliest-established concerns in the conamerrialvehicle industry, and one which, through excellent management and organization, has won a remarkable reputation for its products.

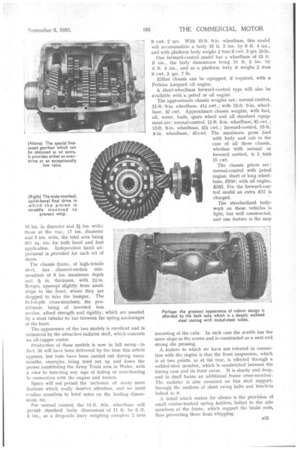

The two new 4-5-ton chassis produced by Commer Cars, Ltd., Luton, are not merely modifications of lighter types, but designed throughout to meet the requirements of the heavier loads and more exacting conditions under which they will be enciployed. These chassis, when fully equipped with cabs and bodies, will weigh under 2i. tons and will, consequently, not only be taxed at the comparatively low figure of £30, but will be able to run at a legal speed of 30 m.p.h.

In view of their lightness, we made a close scrutiny of every part, but could find no unit or detail which did not appear fully capable of standing up to its work. This robustness applies particularly to such important parts as the frame, axles and steering, whilst the tyre equipment is generous, 34-in. by 7-in, heavy-duty pneumatics being fitted all round (those at the rear being twins), all mounted on stout steel disc wheels secured by eight bolts, the .spare wheel being accommodated in a horizontal position under the frame at the rear.

. In their Main characteristics the two chassis are alike, except that one is designed for normal control and the other for forward control, and the neat cabs which have B32

been designed for them permit -three persons to be seated in comfort in the former.

The two are actually rated to carry pay-loads of 4-5tons. With the lighter load, they will probably give -rather longer and more economical service, but the guarantee covers the higher figure, provided the maker's stipulated body weight be not exceeded.

The weight reduction has been attained by scientific

distribution of the materials and the employment of the finest alloy steels obtainable, whilst the opportunity has been taken to embody certain alterations in design, which experience with other models has shown would,. prove advantageous.

Perhaps the first point which appeals to the technical eye is the remarkable cleanliness of the chassis and the absence of "frills." Even the wiring leading to the instrument panel is all enclosed in a single, flexible aluminium conduit.

The only unit which is the same as on the 3-tonner is

the standard four-speed gearbox, because it has proved fully capable of the extra work, but a. five-speed gearbox with over-drive has been produced and can be supplied at a reasonable extra cost. This box has helical, constant-mesh and over-speed gears. An unusual feature is that, if required, a particularly row ratio can be obtained by merely changing two pairs of pinions.

Although the 78-mm.-bore engine used by the maker in certain other chassis has proved highly successful, it has been thought advisable to increase its power and redesign it for its additional task, and the new sixcylindered, side-valve model develops 70 b.h.p. and has bore and stroke dimensions of 85 mm. and 106 Mill. respectively, a compression ratio of 5.86 to 1 and a maximum torque of 1,890 lb.-in., the capacity being 3,609 c.c. Both the crankshaft and camshaft have four bearings, and the silicon-ehrorne--steel valves are in renewable cast-iron guides. White metal is run direct into the big

ends, and the .rods are drilled for forced lubrication. The cast-iron pistons have three compression and one uil-regulating rings, and steel cirelips retain the 24 mm. floating gudgeon pins.

Improvements include a duplicated water inlet from the pump to the cylinder block, and a detachable

cylinder head which, internally ; is slightly 'sloped in the direction of the water flow to obviate any tendency to Icorn steam pockets. . .

Cylinders and crankcase form a one-piece iron-alloy casting, and a Duplex roller . chain with automatic tensibner drives the auxiliaries, the dynamo and water pump being in tandem at the off side. 'Spiral gears on the dynamo driving shaft operate the distributor, and

g,n. eccentric on the shaft of the latter drives the petrol pump. The oil pump is driven from the camshaft, and the fan has an endless rubber V belt.

Petrol is supplied by an A.C. mechanical pump to the Solex Self-Starting carburetter, from a 14-gallon tank carried on brackets at the near side of the frame.

The starter is now flange-mounted on the castaluminium hell housing, and the brackets which 'support the rear of the unit constituting engine, clutch, pedaloperating gear and gearbox, are cast in one with this housing and are bolted to steel brackets secured to the frame side members.

Even the clutch is new, this being a special 12-in. heavy-duty, type, which requires no lubrication or atten tion other -than for wear of the liner, which is taken up by a simple external adjustment shown in one of our drawings.

A two-piece propeller shaft, with two Layrub flexible couplings and a

self-aligning ball-bearing support suspended from a tubular crossmember, carries the drive to spiral bevels with a ratio of 7.14 to 1.

The massive fully floating vertical-banjo back axle is a cast-steel casing with deep webs, reinforced

by nickel%steel. tubes, whilst the driVing shafts are of -Vibrac fatigue

resisting' steel with large splines at the inner ends and integral flanges • of large diameter at • the outer ends, the hubs being secured to these by fitted high-tensile bolts. It has been found that if studs once become loose they can never be tightened. Silico-manganese steel is used for the springs, in each of which the master leaf is double-wrapped at the eye, whilst the second leaf is half-wrapped around this. Renewable steel bushes take the wear.

The front axle is a stout nickel-chrome-steel drop forging with stub axles of the reversed Elliott type, and the kingpins are set to approximate closely to centrepoint steering.

Special attention has been giren to the steering layout. The rocker shaft is of 11-in. diameter and the 1i-in ball pins have dust-excluding rubber gaiters. The drop arm, drag link and track rod with its self-adjusting eccentric ends, are much stouter than in the 3-tonner and can be well compared in the photographs reproduced.

Braking with a vehicle of this capacity is of vital moment. The shoes are of the Bendix Duo-servo pattern, self-energizing in both directions. Those at the front are 16 ins in diameter and 24 ins, wide; those at the rear, 17 ins. diameter and 3 ins, wide, the total area being 38:i sq. ins, for both hand and foot application. Independent hand adjustment is provided for each set of shoes.

The chassis frame, of high-tensile steel, has channel-section side members of 8 ins, maximum depth

and 4 in. thickness, with 2/-in. fthnges, upswept slightly from amidships to the front, where they are

dropped to take the bumper. The full-depth cross-members, the penultimate being of inverted box section, afford 'strength and rigidity, which are assisted by a stout tubular tie bar between the spring anchorages at the front.

The-appearance of the two models is excellent and is enhanced by the attractive radiator shell, which, conceals an all-copper centre.

Production of these models is now in full swing-----in fact, 50 will have been delivered by the time this article appears, but tests have been carried out during many months, examples being tried out up and down the passes constituting the Army Trials area in Wales, with a view to detecting any sign of fading or over-heating in connection with the engine and brakes.

Space will not' permit the inclusion of many more features which really deserve attention, and we must confme ourselves to brief notes on the leading dimen.

se-ma, etc: , POInormal control, the 11-ft. 9-in. wheelbase will permit sta,ndard body dimensions of 11 ft. by 6 ft. 4 ins., as a drop-side lorry weighing complete 2 tons

9 cwt. 2 qrs. With 13-ft. 9-in, wheelbase, this model will accommodate a body. 13 ft. 3 ins. by 6 ft. 4 ins., and with platform body weighs 2 tons 0 cwt. 3 qrs. 20 lb.

One forward-control model has a wheelbase of 13 -ft. 9 ins., the body dimensions being 15 ft. 6 ins. by 6 ft. 4 ins., and as a platform lorry it weighs 2 tons 9 cwt. 3 qrs. 7 lb.

Either chassis can be equipped-, if required, with a Perkins Leopard oil engine.

A short-wheelbase forward-control type will also be available with a petrol or oil engine:

The approximate chassis weights are : nornial-control, 11-ft. 9-in. wheelbase, 411 cwt. ; with 13-ft. 9-in. wheelbase, 42 cwt. Approximate chassis weights, with fuel, oil, water, tools, spare wheel and all standard equipment are normal-control, 1.1-ft. 9-in, wheelbase,:45 cwt. ; 13-ft. 9-in. wheelbase, 45i cwt. ; forward-control, 13-ft. 9-in. wheelbase, 45-cwt. The maximum gross. load with body and cab in the case of all these chassis, whether' with normal or forward control, is 5 .„-toriS 15 cwt.

The chassis prices are: normal-control with petrol engine, short, or long wheelbase, £350; with oil engine, £535. For the forward-control model an extra £15 is charged.

The standardized bodywork on these vehicles is light, but well constructed, and one feature is the easy mounting of the cabs. In each case the scuttle has the same slope as the screen and is constructed as a neat and strong die pressing.

A feature to which we have not referred in connection with the engine is that the front suspension, which is at two points, as at the rear, is effected through a welded-steel member, which is sandwiched between the timing case and its front cover. It is sturdy and deep, and in itself forms an additional frame cross-member. The radiator is also mounted on this steel support, through the medium of short swing bolts and brackets bolted to it.

A detail which makes for silence is the provision of small rubber-bushed spring holders, bolted to the side members of the frame, which support the brake rods, thus preventing these from whipping.